Unsaturated coarse-grained soil permeameter and test method thereof

A permeameter and coarse-grained soil technology, applied in the field of geotechnical engineering, can solve the problems of limitation, not more than 10kPa, difficult to measure the inflow and outflow water, wide range of particle size of coarse-grained soil, etc. The effect of shortening the time required for testing and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

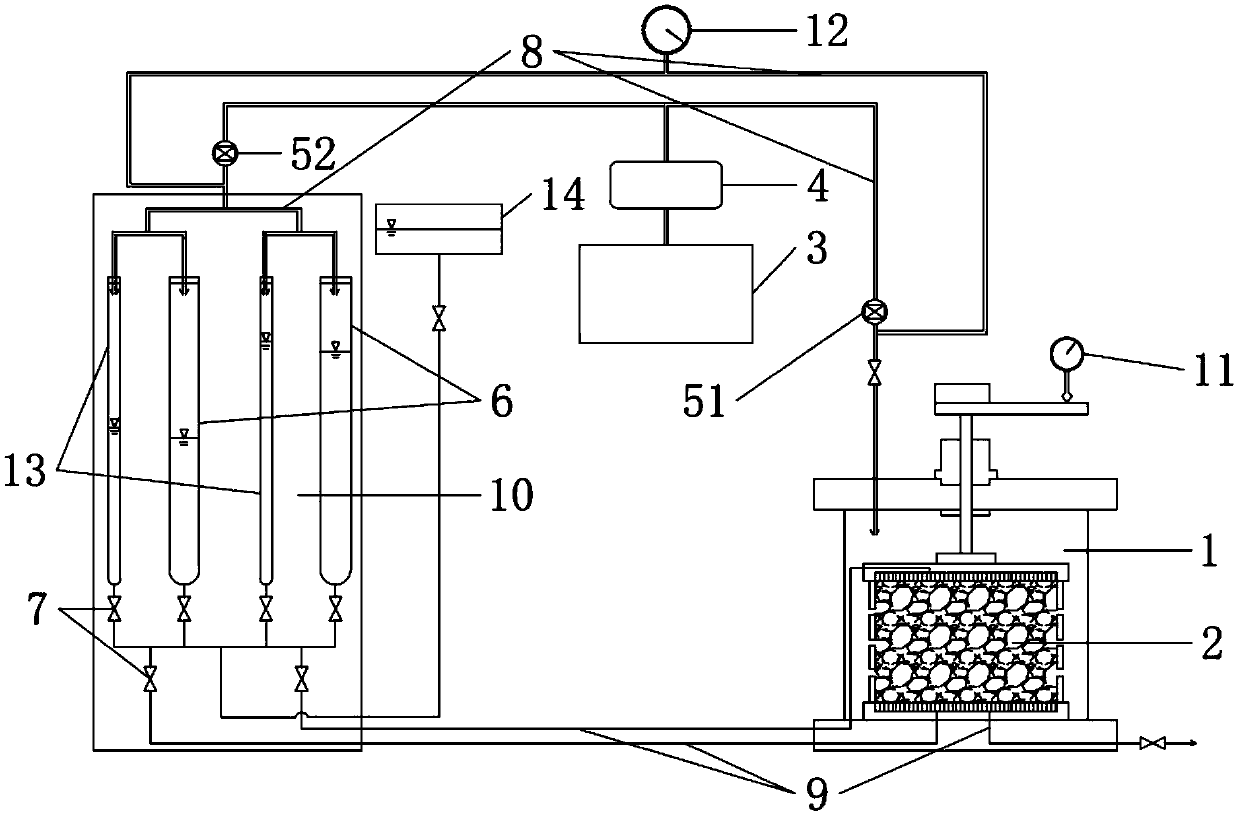

[0041] Such as figure 1 As shown, the unsaturated coarse-grained soil permeameter of the present embodiment consists of an outer chamber 1, an inner chamber 2, an air compressor 3, a filter bottle 4, and a pressure regulating valve 5 (comprising a first pressure regulating valve 51 and a second pressure regulating valve 52), pressurized pipe 6 (comprising upper pressurized pipe and lower pressurized pipe), valve 7, air guide pipe 8, water guide pipe 9, measuring platform 10, dial gauge 11, barometer 12, measuring pipe 13, water tank 14 composition.

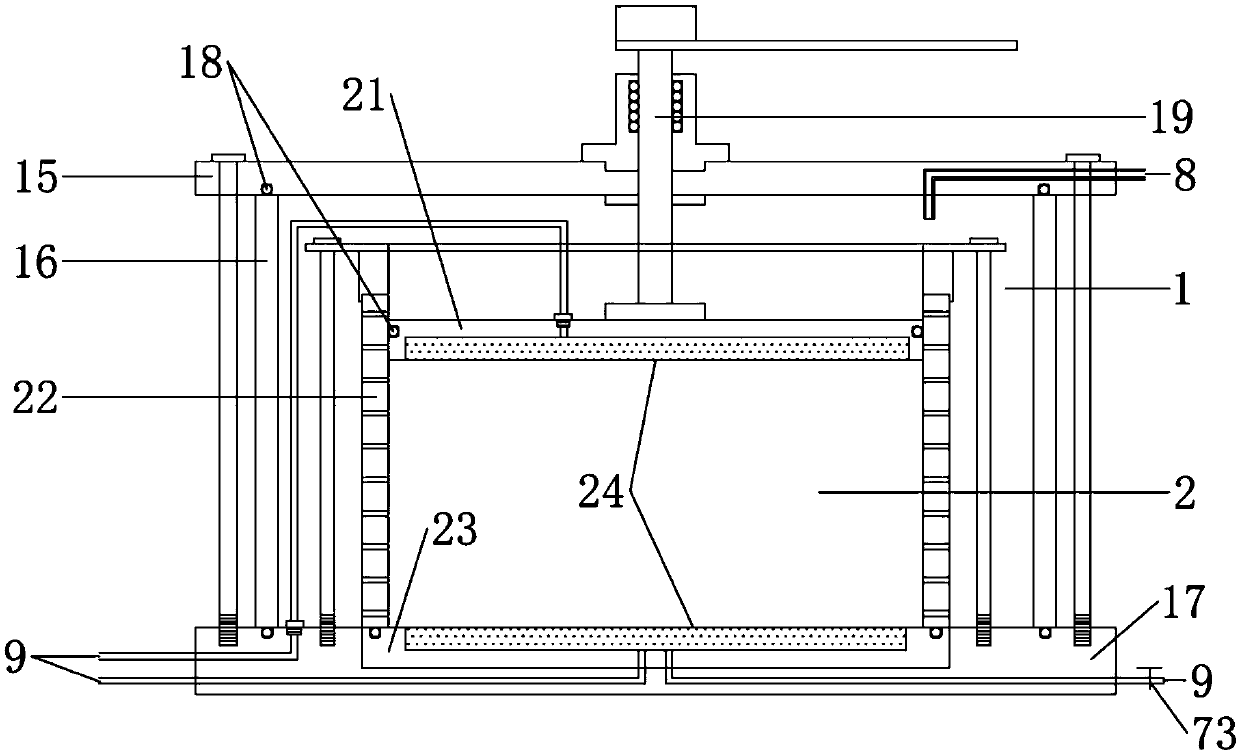

[0042] Such as figure 2 As shown, the sealed chamber is composed of an outer chamber 1 and an inner chamber 2; the top cover 15, the outer sleeve 16 and the base 17 are sealed with an O-ring 18 to form the outer chamber 1; a loading rod 19 is installed on the top cover 15, and It is connected with an air guide pipe 8, which is connected to the air compressor 3 through the air guide pipe 8, and is used to fill the outer chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com