A method to achieve cross-scale lithography or multi-resolution imaging by changing the beam expansion ratio

A multi-resolution, cross-scale technology, applied in the direction of microlithography exposure equipment, optics, optical components, etc., can solve problems such as alignment errors, and achieve the effect of simple operation, fast speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

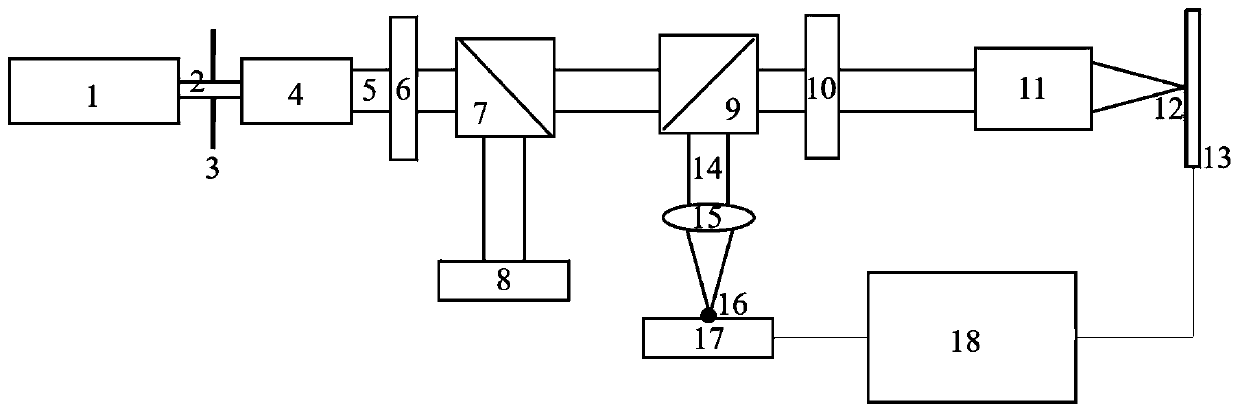

[0031] The present invention realizes the method of cross-scale lithography or multi-resolution imaging by changing the ratio of beam expansion. The single-beam point scanning lithography or imaging system sequentially includes a diaphragm 2, a beam expander, and a half-wave plate 6 along the output direction of the optical path. , beam splitter 7, polarization beam splitter 9, quarter wave plate 10 and objective lens 11, its steps include:

[0032] 1) Replace the beam expander with an electric adjustable magnification beam expander 4, whose magnification is continuously adjustable from 1 to 64 times;

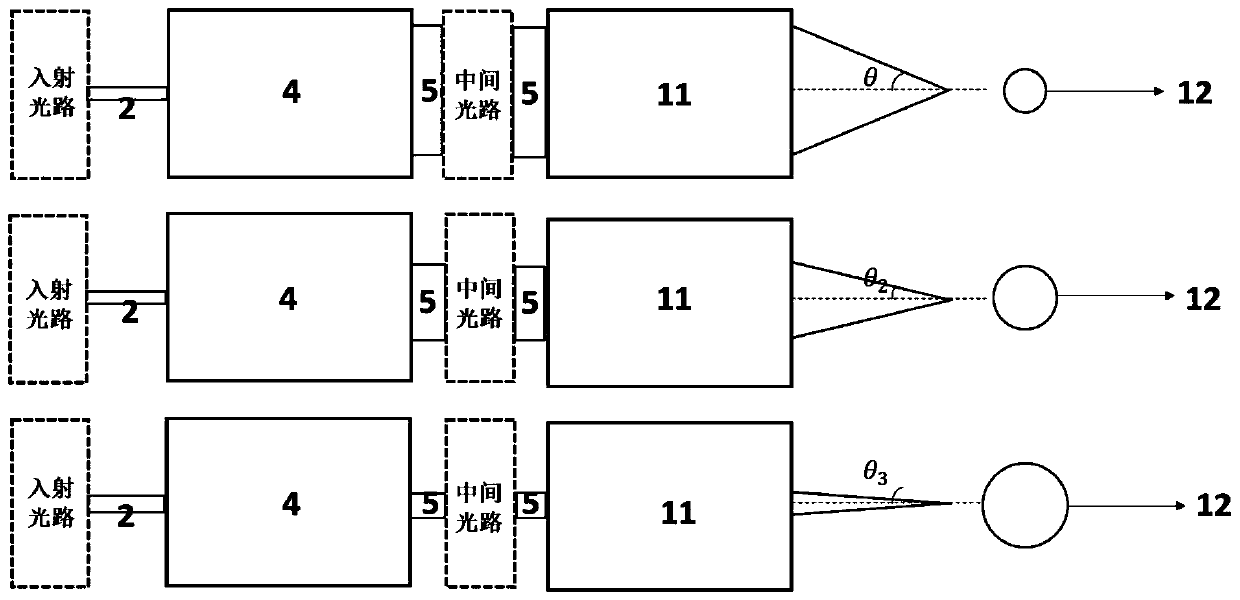

[0033] 2) Adjust the magnification of the electrically adjustable magnification beam expander 4 to m times, so that the beam 5 after the beam expansion is identical to the diameter of the entrance pupil of the objective lens 11;

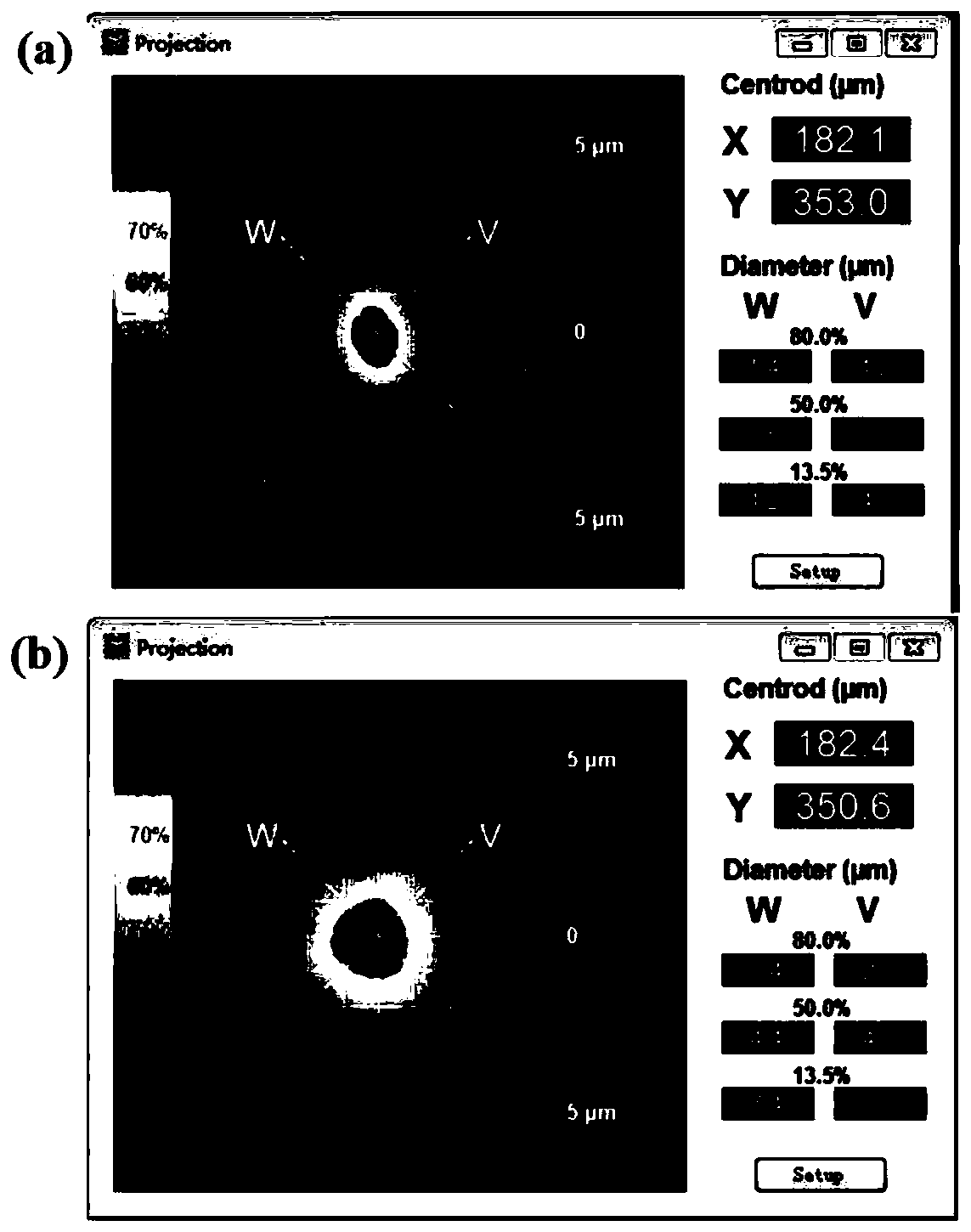

[0034] 3) according to formula D=1.22λ / NA, calculate the diameter D of focus light spot 12 after light beam 5 passes through objective lens 11 in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com