Wire tube fixing clamp

A technology of fixing clips and wire tubes, applied in the direction of electrical components, etc., can solve the problems of deviation and offset in the installation position of the distribution box, and the holes of the distribution box cannot match the pre-embedded wire tubes, etc., so as to increase the utilization rate , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

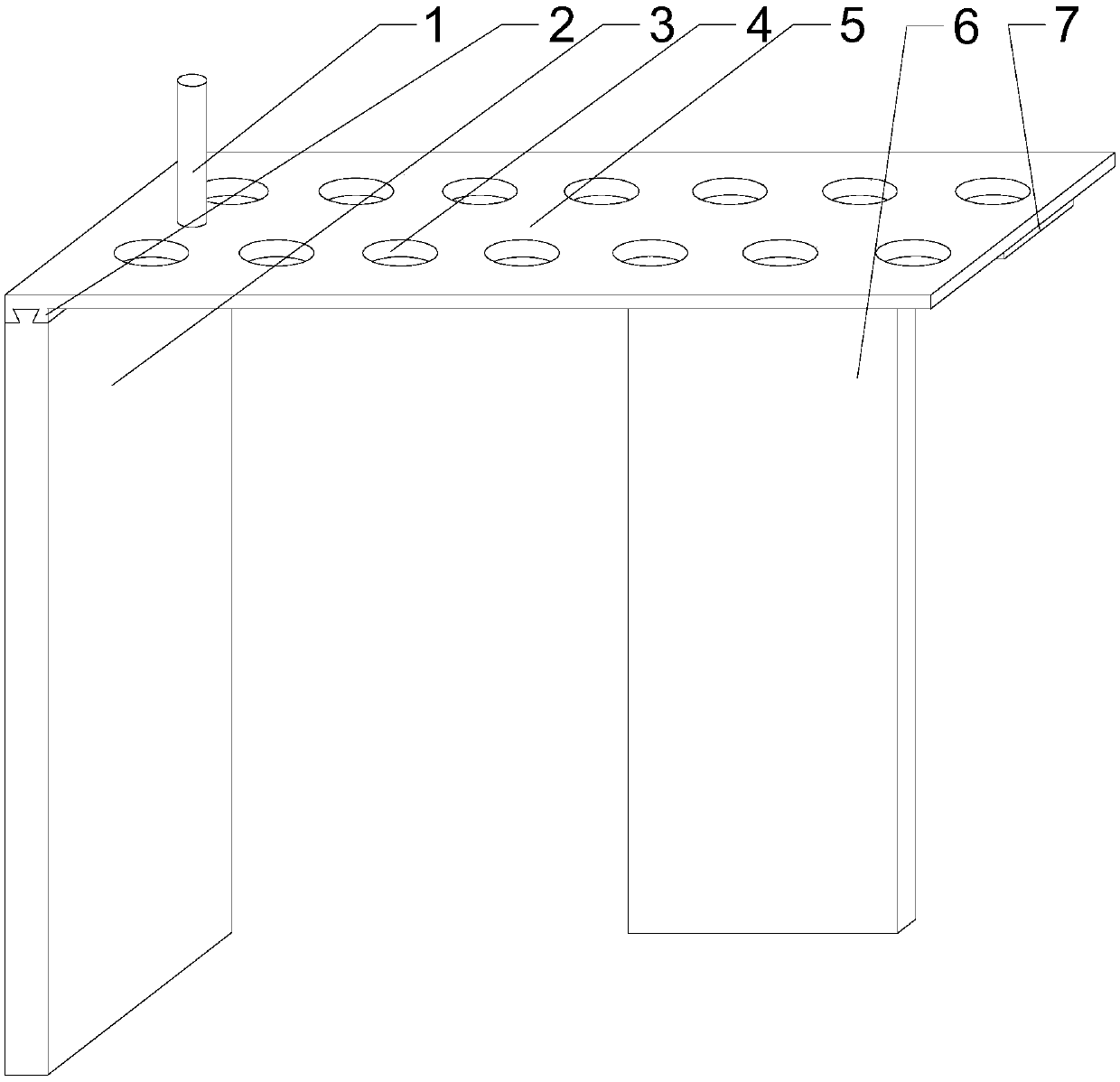

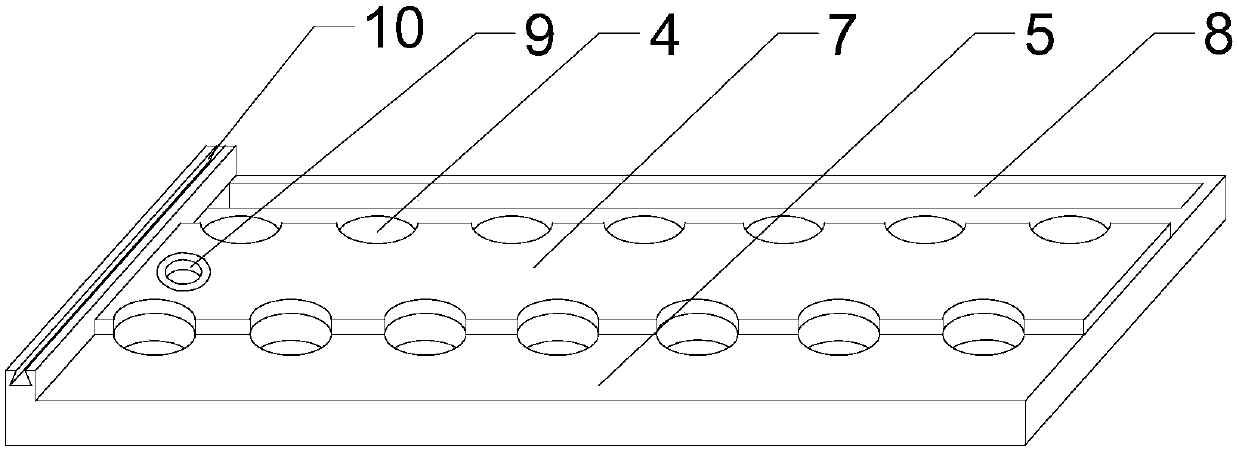

[0022] Such as Figure 1~2 As shown, the present embodiment includes a rectangular support plate 5 and a side plate 3, a plurality of limit holes 4 are opened on the support plate 5, and corrugated strips 2 are arranged on the lower surface of the support plate 5, and the corrugated strips 2 There is a trapezoidal groove 10 with a length equal to that of the corrugated strip 2, a protrusion matching the trapezoidal groove 10 is provided on the upper end surface of the side plate 3, and a vertical groove with the corrugated strip 2 is also provided on the lower surface of the supporting plate 5. chute 8, and both ends of the chute 8 are closed, the upper end of the movable plate 6 is slidingly arranged in the chute 8, and the support plate 5, the side plate 3 and the movable plate 6 constitute a limiting platform for fixing the pre-embedded pipe . In view of the existing technology, after the pre-embedded line pipe is deployed, it is easy to shift during the later civil brickl...

Embodiment 2

[0025] Such as Figure 1~2 As shown, in this embodiment, the plurality of limiting holes 4 are distributed into two groups along the long side of the support plate 5 , and the plurality of limiting holes 4 in the same group are distributed at equal intervals. The distribution of multiple holes on the distribution box is relatively uniform. In order to improve the centering efficiency between the pre-embedded wire pipe and the holes, the multiple limiting holes 4 on the support plate 5 are divided into two groups, and each group of limiting holes 4 is along the The long sides of the support plate 5 are evenly distributed to avoid excessive deformation when the pre-embedded wire tube passes through the limiting hole 4, and ensure that the cable enters the distribution box smoothly when the cable is deployed.

[0026] The present embodiment also includes a dividing plate 7 placed on the lower surface of the supporting plate 5, a screw hole is provided on the supporting plate 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com