Flexible shell and preparation method thereof

A flexible shell and shell technology, which is applied in the direction of casing/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, shell with display/control unit, etc., can solve the problem of easily damaged flexible shaft, shell, etc. Short service life of the body, dust and other problems, to reduce the risk of tensile fracture and meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

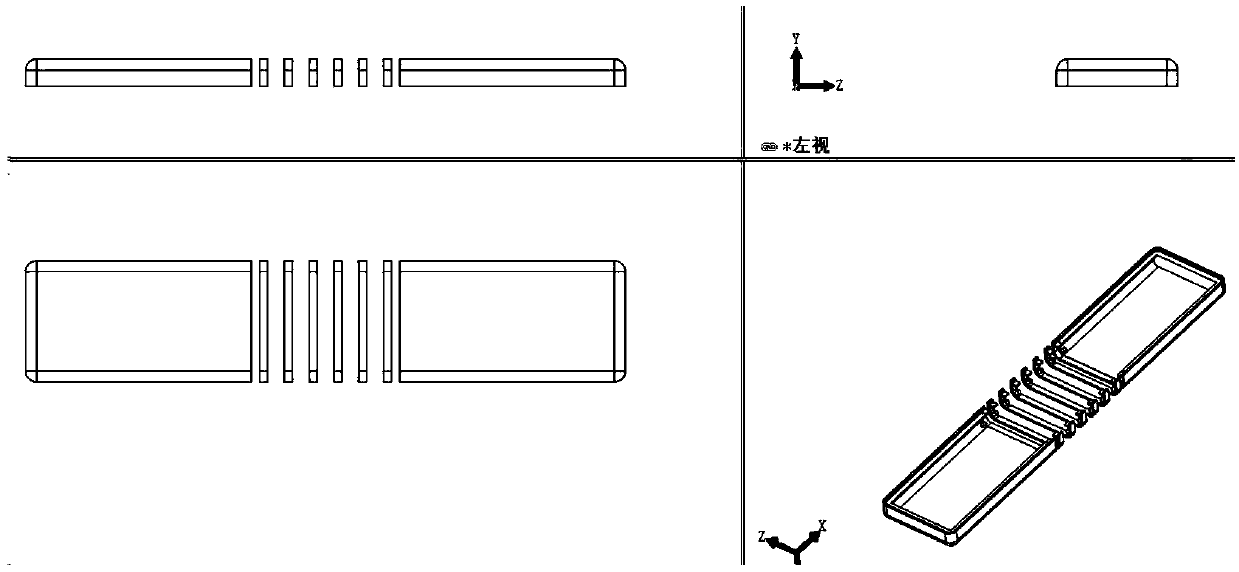

[0044] The invention provides a flexible housing, comprising:

[0045] a rigid backbone comprising at least two separate rigid components;

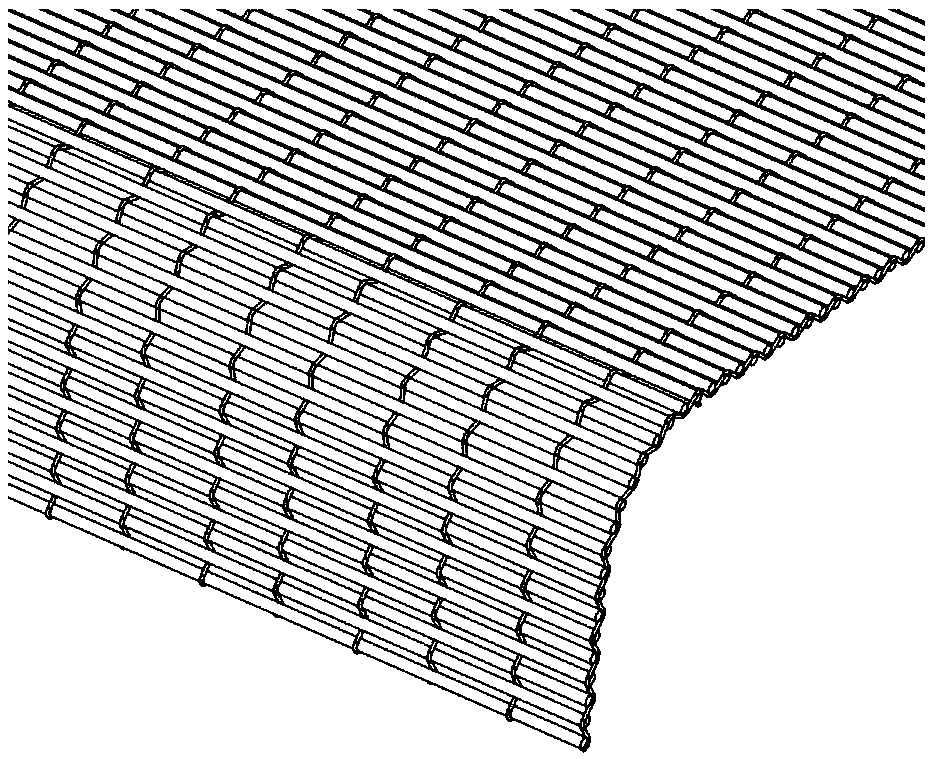

[0046] An elastic fiber net, the two ends of the elastic fiber net are respectively fixedly connected with two rigid components to form a bendable part;

[0047] a flexible shell, the flexible shell wraps at least the outer surface of the elastic fiber net;

[0048] In the state where the elastic fiber web is not subjected to bending force, the area of the flexible shell corresponding to the elastic fiber web has wrinkles.

[0049] The rigid frame comprises at least two separate rigid components forming the frame of the housing.

[0050] The elastic fiber net is arranged in the interval area between the two separated rigid components, and is fixedly connected to the two rigid components through two ends respectively, forming a bendable part, which is used for the shell to achieve the function of bending.

[0051] Preferably, one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com