Hot-press protection release colloid and uses of the same

一种离型胶、离型膜的技术,应用在胶粘剂、粘合剂类型、聚脲/聚氨酯粘合剂等方向,能够解决硅油析出、层板或芯片伤害、工艺适用条件限制等问题,达到轻易离型、解决段差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

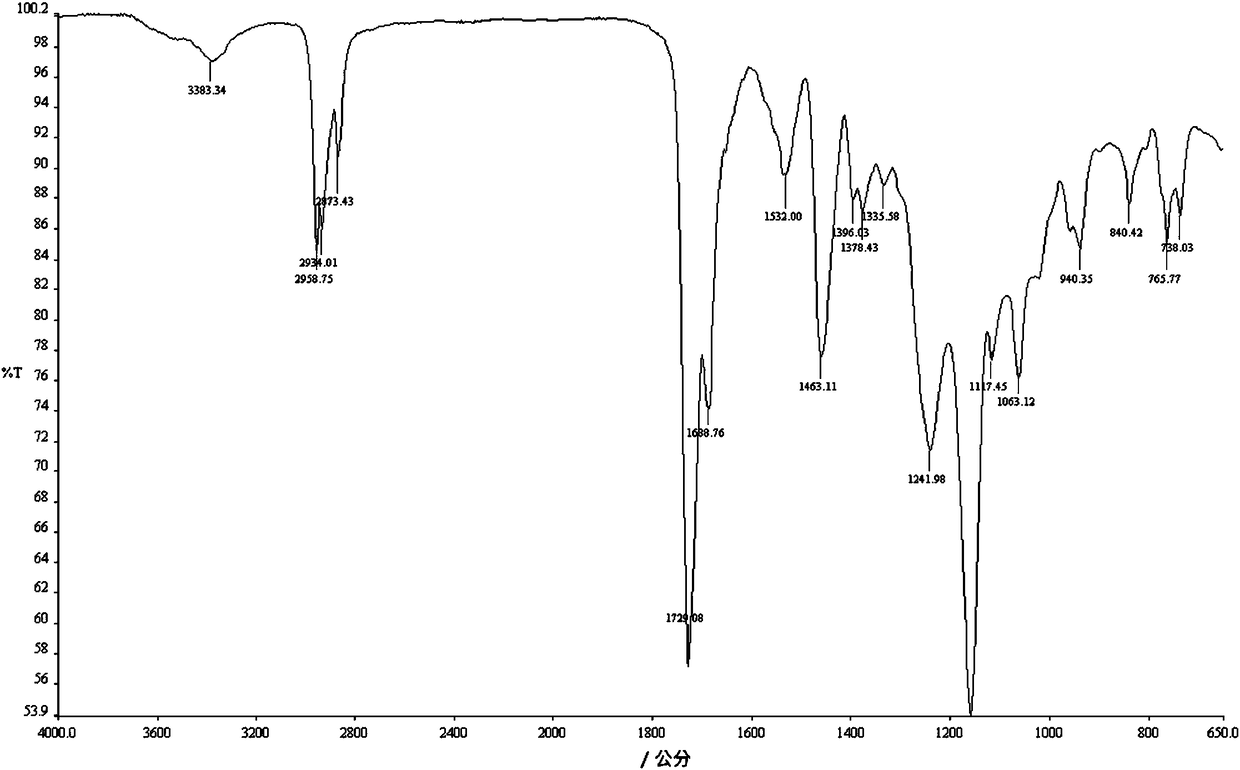

Image

Examples

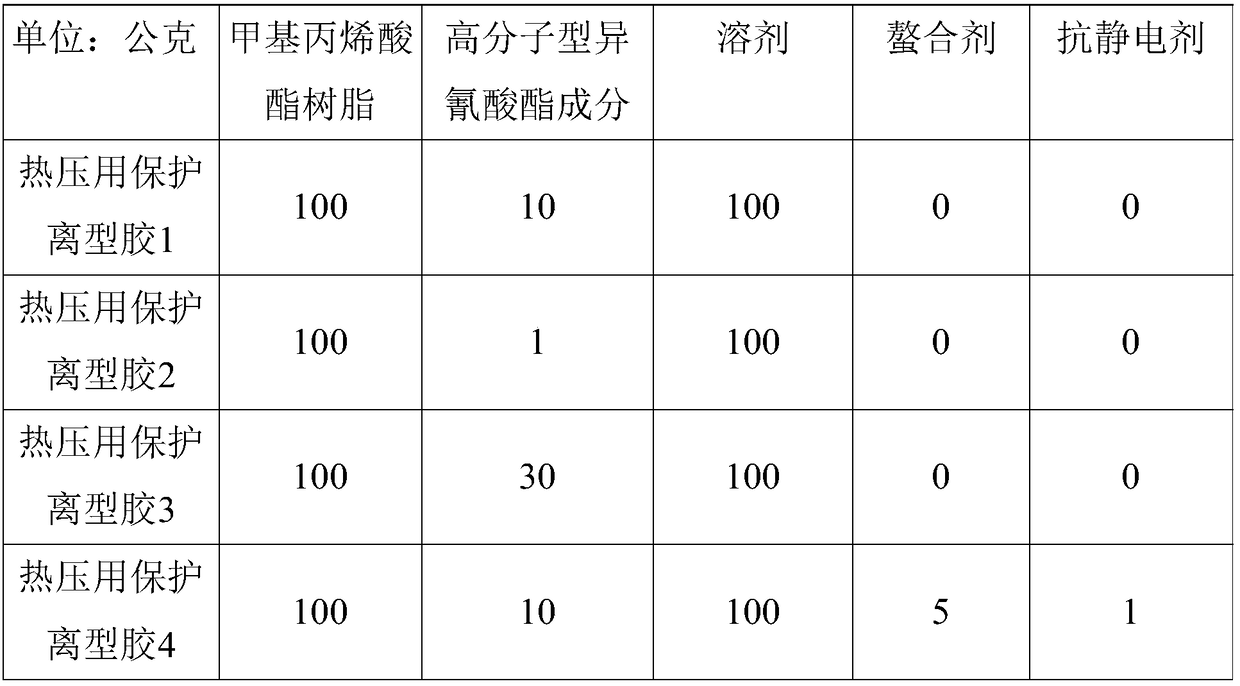

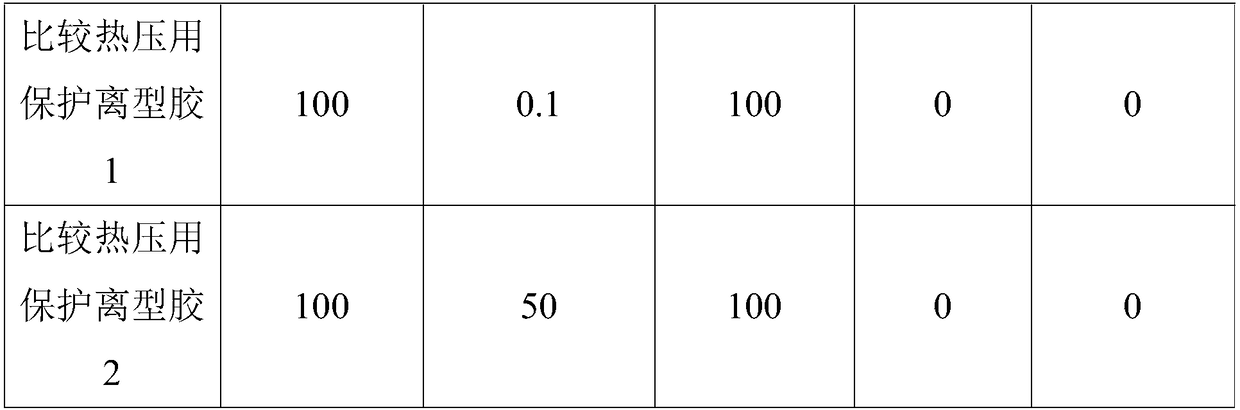

preparation example Construction

[0041] Preparation method of protective release film for hot pressing

[0042] The present invention additionally provides a method for preparing the above-mentioned protective release film for hot pressing, the method comprising: performing a heating and drying procedure and the aforementioned aging procedure on the protective release adhesive for hot pressing of the present invention to form a protective release film for hot pressing. Protective release layer, wherein, the protective release layer for hot pressing can be formed separately, or can be coated with a protective release adhesive for hot pressing on the surface of a substrate, and then carry out the heating and drying process and the aging process to form formed on the surface of the substrate.

[0043] The heating method, heating temperature and heating time of the above-mentioned heating and drying procedure are not particularly limited, as long as most of the solvent of the protective release adhesive for hot p...

Embodiment 1

[0088] [Example 1: Preparation of protective release film for hot pressing]

[0089] Use protective release adhesive 1 for hot pressing to protective release adhesive 4 for hot pressing, and protective release adhesive 1 for comparative hot pressing and protective release adhesive 2 for comparative hot pressing to prepare protective release film for hot pressing 1 to protective release film 4 for hot pressing, and protective release film 1 for comparison hot pressing and protective release film 2 for comparative hot pressing. First, the protective release adhesive for hot pressing 1 to the protective release adhesive for hot pressing 4 and the protective release adhesive for hot pressing 1 and the protective The release adhesive 2 is respectively coated on the PET substrate, heated and dried at 180°C for 2 to 5 minutes to form a protective release layer for hot pressing on the surface of the PET substrate, and then the following aging procedure is carried out to obtain a hot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com