Preparation method of a semi-liquid bulletproof thorn composite material, bulletproof thorn composite material and bulletproof thorn protective inner core

A composite material and anti-bullet thorn technology, which is applied in protective clothing, protective equipment, protective equipment, etc., can solve the problems of poor air permeability, prone to ricochets, poor flexibility, etc., and achieve passivation of tool heads, stable bulletproof performance, and system The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a semi-liquid bulletproof thorn composite material, comprising the following steps:

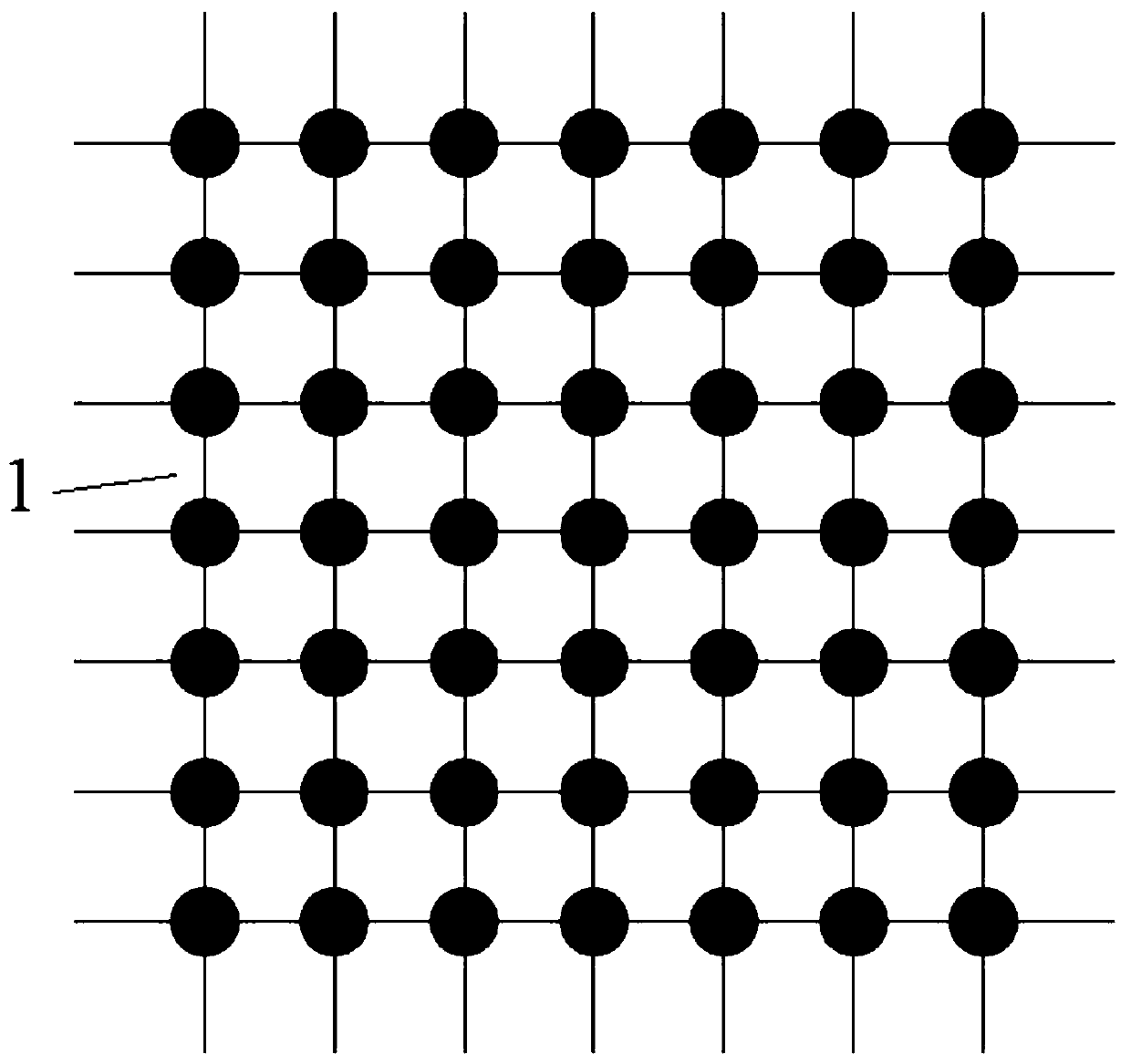

[0041] Step 1. Preparation of thermosetting resin grid

[0042] preparing a thermosetting resin / hard particle solution, uniformly coating the thermosetting resin / hard particle solution on the grid, and curing the coated grid to obtain a thermosetting resin grid;

[0043] Step 2. Preparation of SiO 2 / PEG mixed system solution;

[0044] Step 3, preparing semi-liquid bulletproof thorn composite material

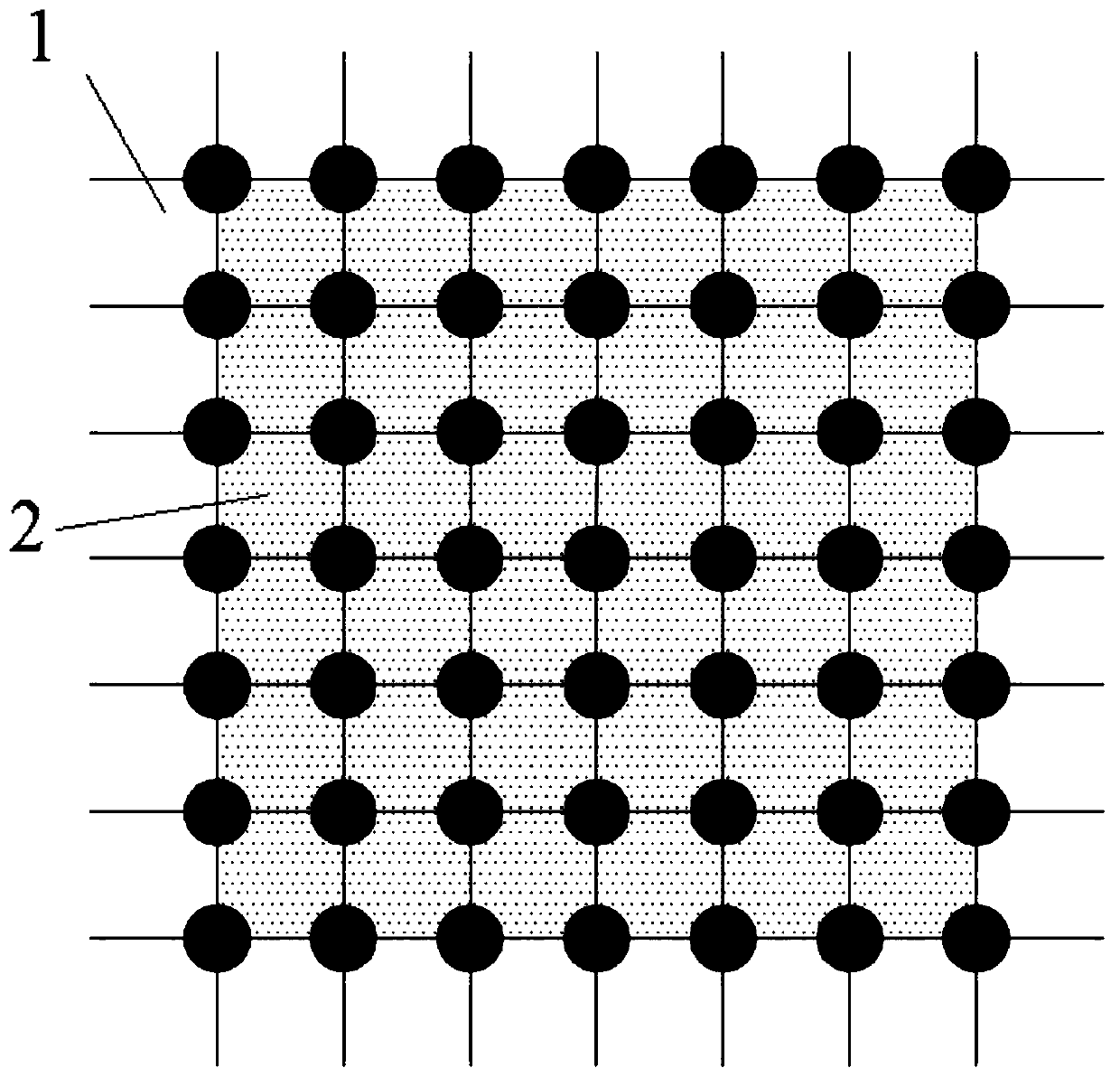

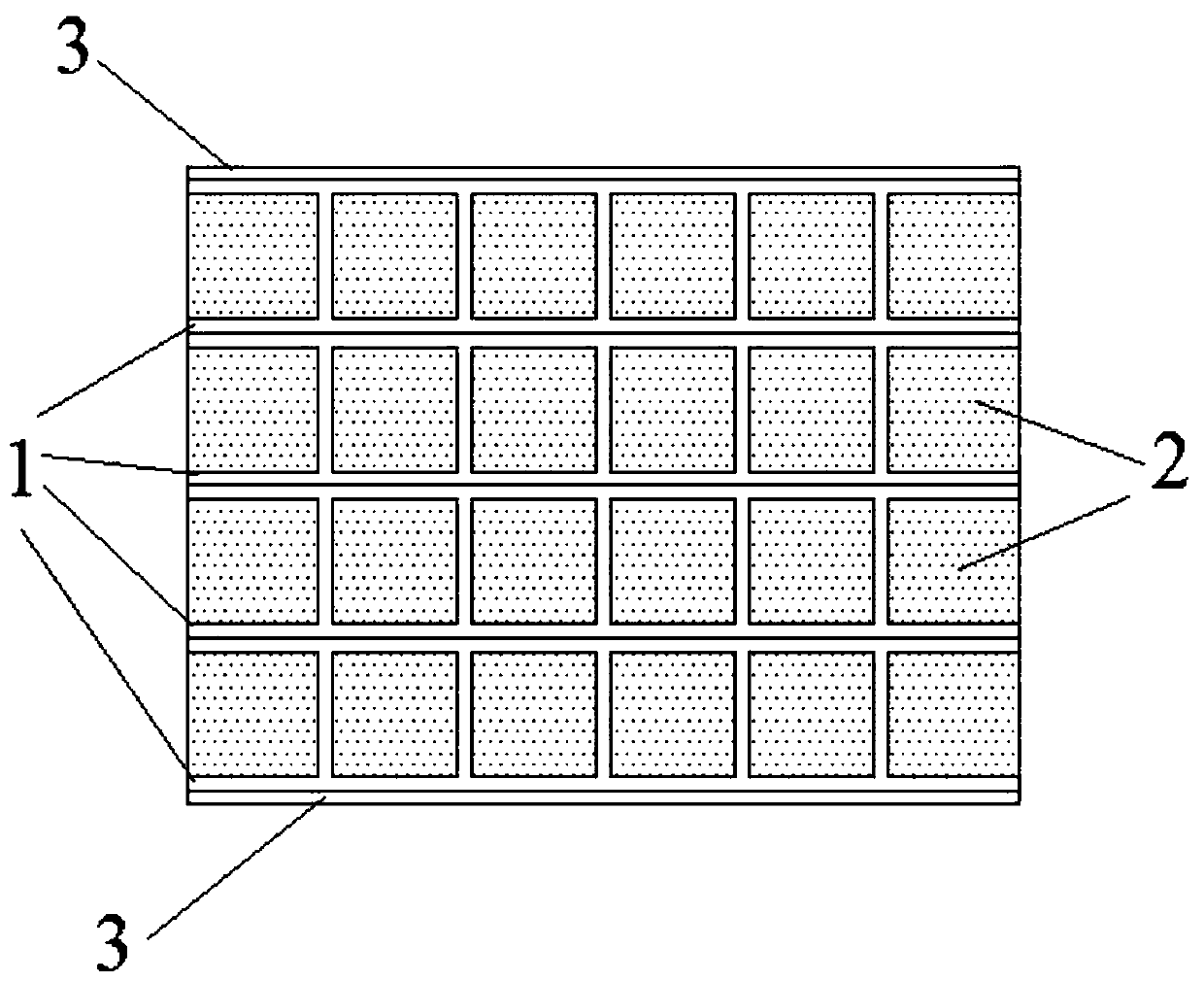

[0045] Lay at least one layer of the thermosetting resin grid on a high-performance fabric according to a certain laying angle, and place the SiO 2 / PEG mixed system solution is uniformly coated in the mesh of the thermosetting resin grid, and a high-performance fabric is spread on the uppermost layer of the thermosetting resin grid to obtain the initial composite material, and the initial composite material is covered with a heat-resistant adhesive tape. The...

Embodiment 2

[0062] Adopt the preparation method of embodiment 1 to prepare semi-liquid bulletproof thorn composite material, concrete steps are as follows:

[0063] Step 1: Prepare Thermoset Resin Grid

[0064] Select high-strength and high-toughness epoxy resin, silicon carbide, and dioctyl phthalate toughening agent to prepare thermosetting resin / hard particle solution. Among them, the curing agent is polyamide resin curing agent, the mass ratio of high-strength and high-toughness epoxy resin to polyamide resin curing agent is 1:0.6, the particle size of silicon carbide is 50 μm to 90 μm, and the solid content of silicon carbide in the resin solution is 18 %, the addition of dioctyl phthalate toughening agent is 4%.

[0065] Spread a layer of grid on the release paper, the grid is an aramid fiber grid, the grid size is 6mm×6mm, and the thickness of the grid is 0.5mm.

[0066] Apply the prepared thermosetting resin / hard particle solution evenly on the grid, especially at the intersecti...

Embodiment 3

[0074] Adopt the preparation method of embodiment 1 to prepare semi-liquid bulletproof thorn composite material, concrete steps are as follows:

[0075] Step 1: Prepare Thermoset Resin Grid

[0076] Select high-strength and high-toughness epoxy resin, corundum, dioctyl phthalate toughening agent to prepare thermosetting resin / hard particle solution. Among them, the curing agent is polyamide resin curing agent, the mass ratio of high-strength and high-toughness epoxy resin to polyamide resin curing agent is 1:0.6, the particle size of corundum is 80 μm to 140 μm, and the solid content of corundum in the resin solution is 12%. The addition amount of dioctyl phthalate toughening agent is 3%.

[0077] Spread a layer of grid on the release paper, the grid is a polyethylene grid, the grid size is 12mm×12mm, and the thickness of the grid is 0.4mm.

[0078] Apply the prepared thermosetting resin / hard particle solution evenly on the grid, especially at the intersection of the grid (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com