Active infrared thermal image detecting device and method for internal defects of composite insulator

A technology for composite insulators and internal defects, applied in measuring devices, radiation pyrometry, measuring electricity, etc., can solve problems such as low sensitivity, high requirements for detection conditions, and destructiveness, and achieve the effect of solving low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

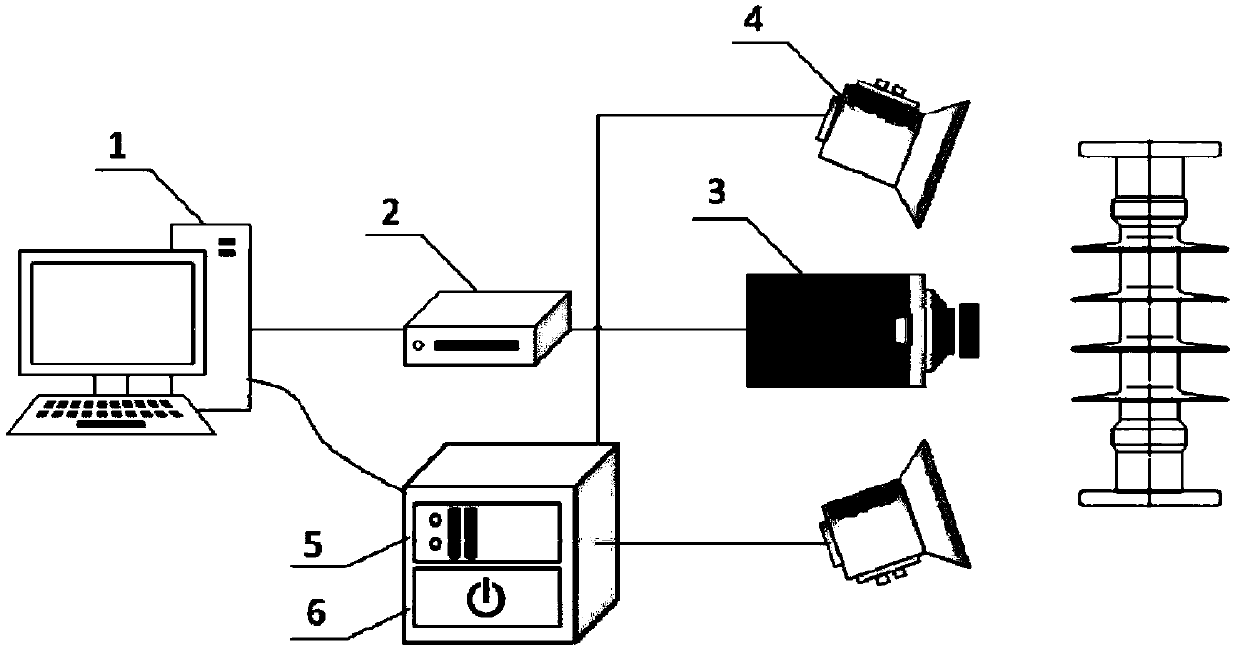

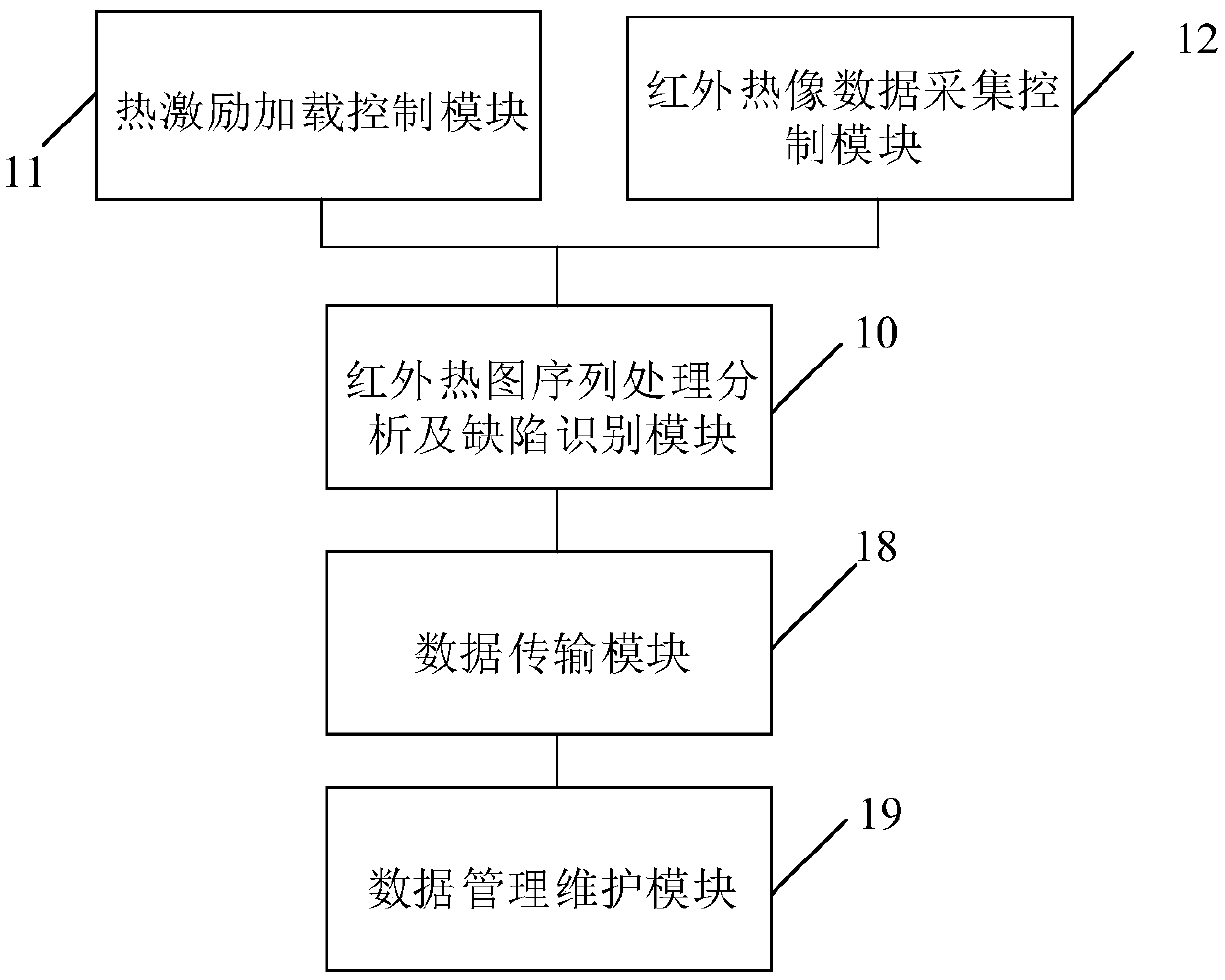

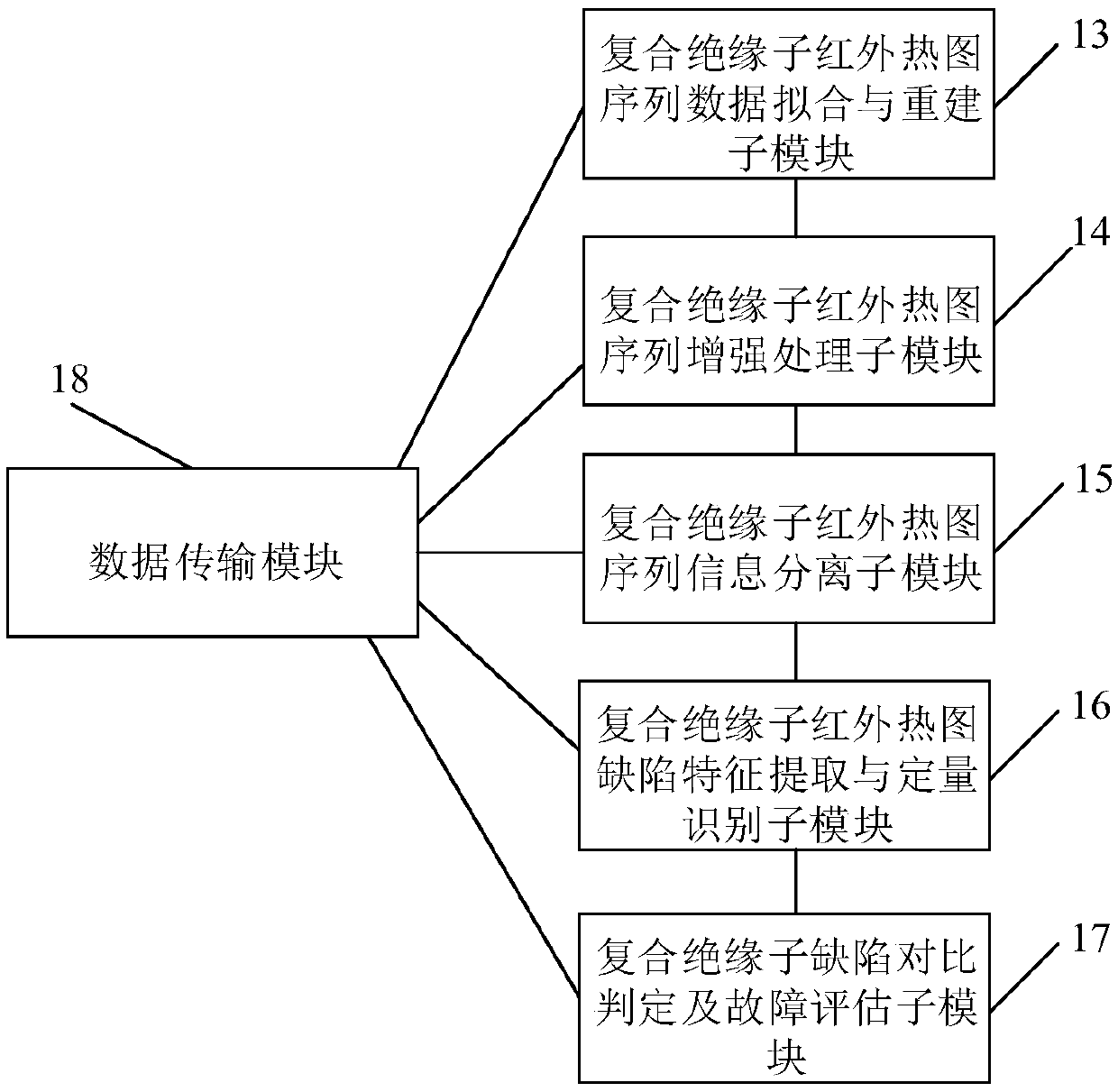

[0049] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the active infrared thermal image detection device for the internal defects of the composite insulator, figure 2 It is a structural block diagram of the control and data processing and analysis device provided by the embodiment of the present invention.

[0050] An active infrared thermal image detection device for internal defects of a composite insulator provided by an embodiment of the present invention includes a modulating optical radiation thermal excitation loading device, an infrared thermal image acquisition device, and a control and data processing and analysis device 1;

[0051] The modulating optical radiation thermal excitation loading device and the infrared thermal image acquisition device are respectively connected to the control and data processing and analysis device 1;

[0052] The modulating optical radiation thermal excitation loading device is composed of an opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com