Pressure regulating valve

A technology of pressure regulation and regulator, applied in the field of pressure regulating valves, which can solve the problems of high cost and achieve the effect of low wear and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

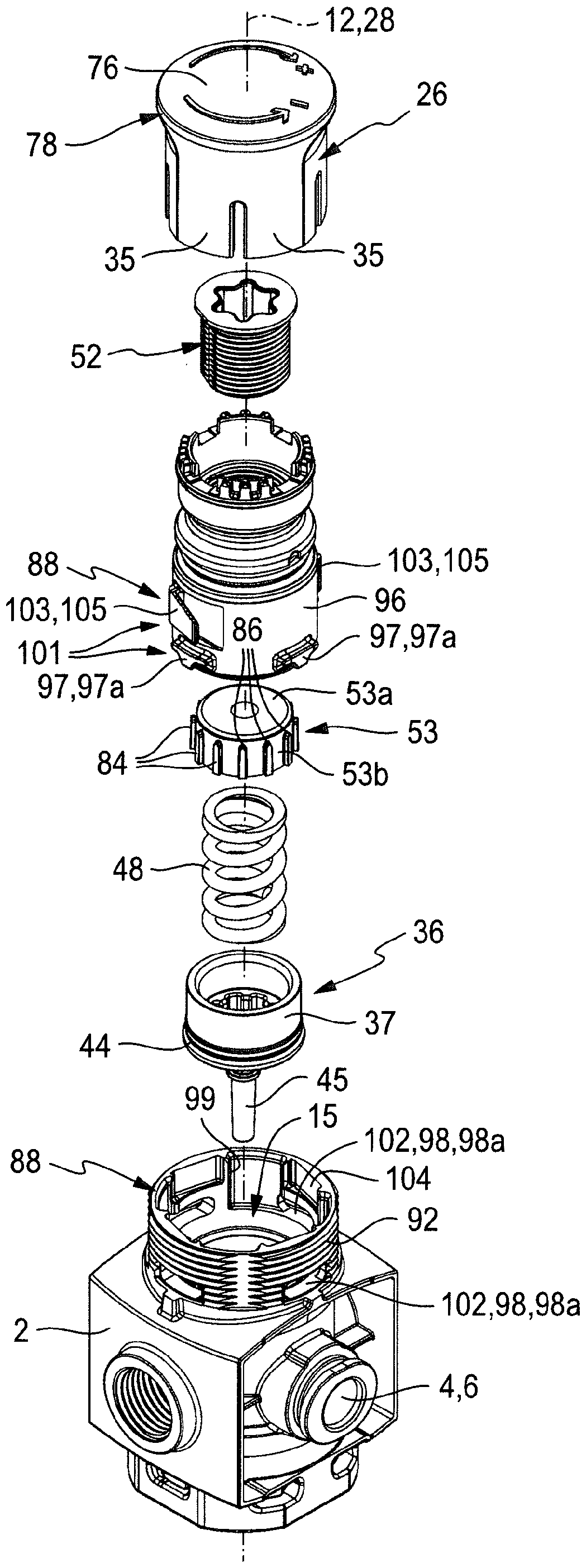

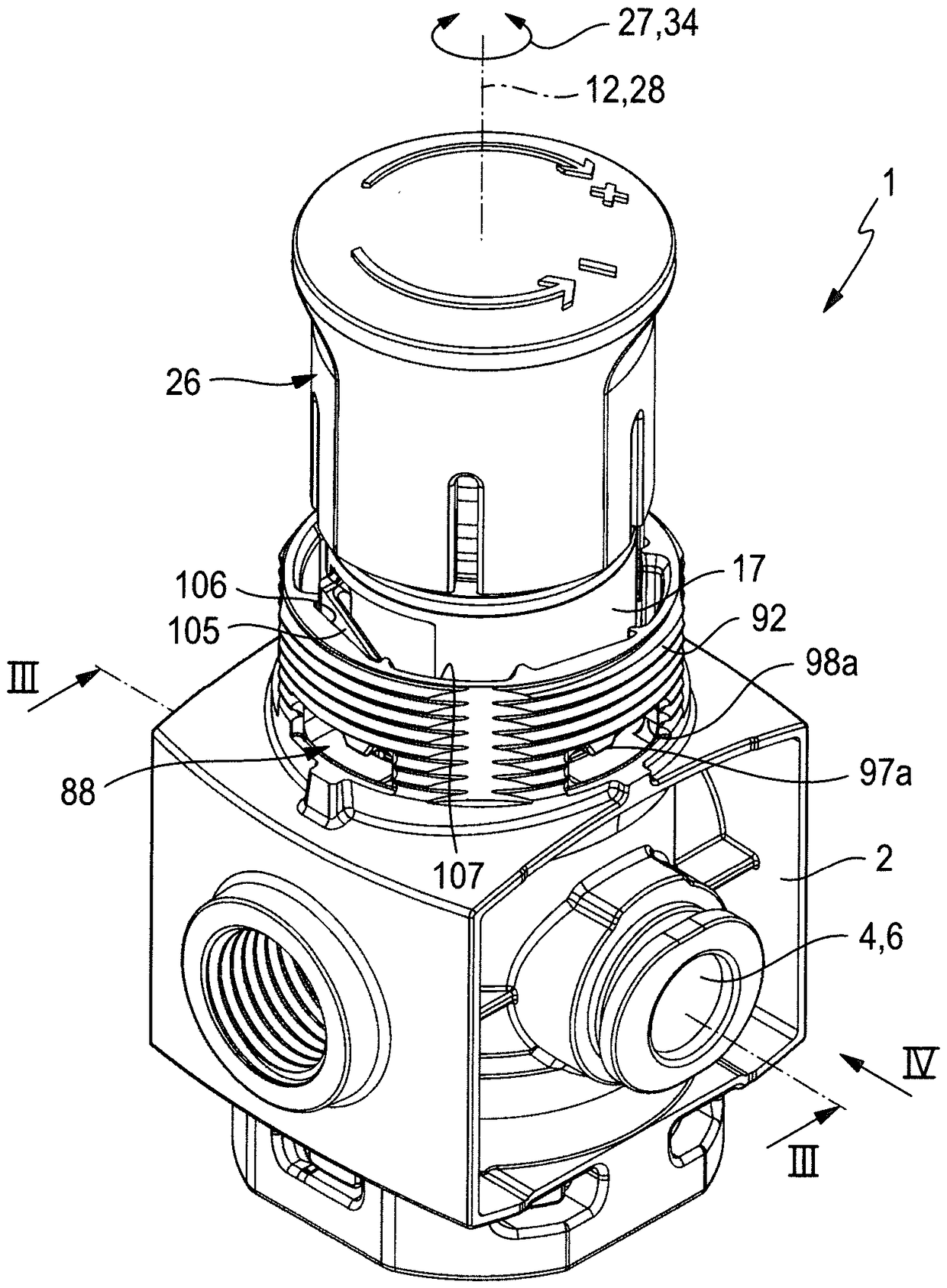

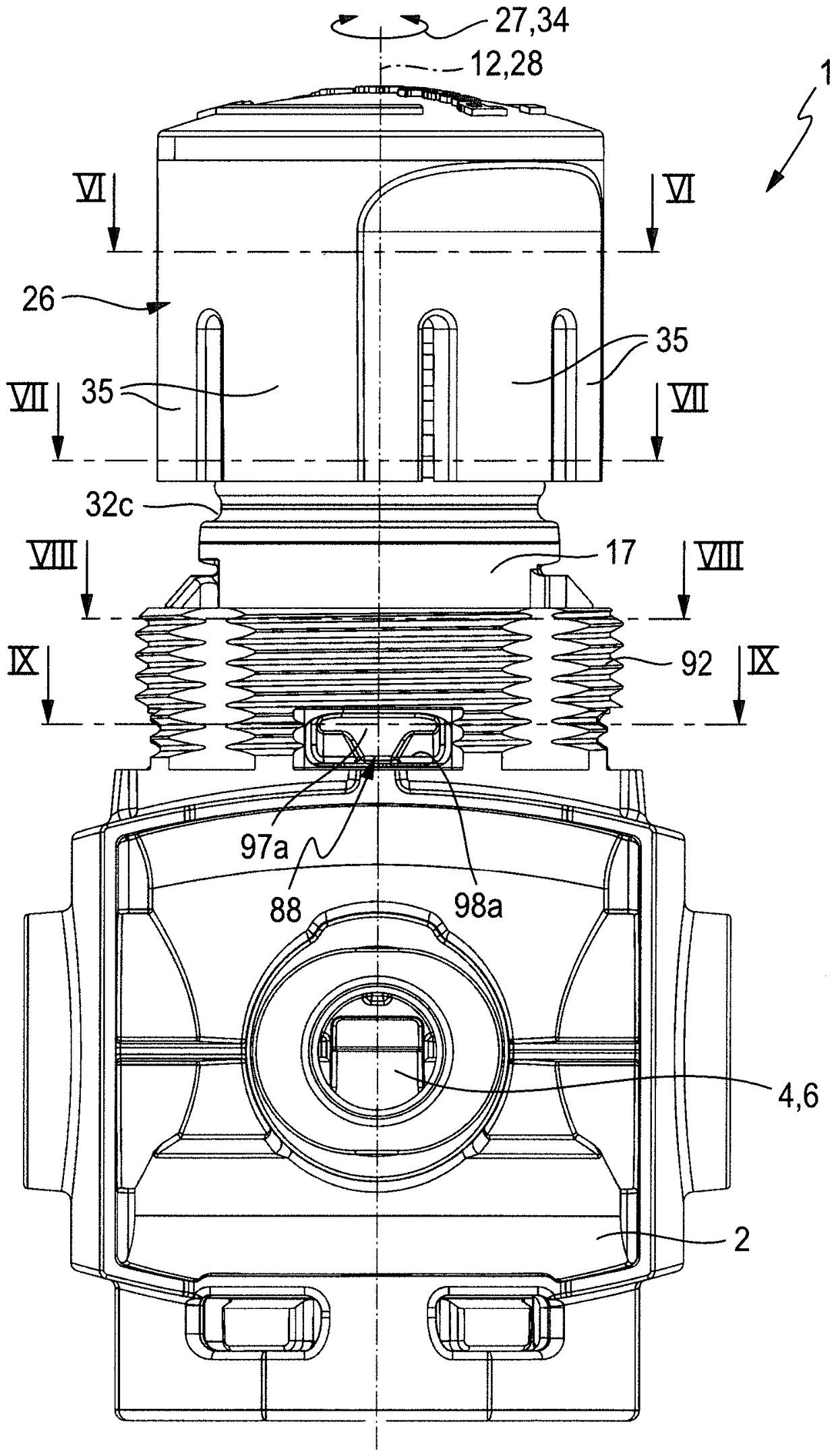

[0036] The pressure regulating valve 1 illustrated in the drawing has a regulator housing 2 in which flow channels run, referred to as primary channel 3 and secondary channel 4 , which At different (in particular opposite) housing outer surfaces of the regulator housing 2 , there is an opening via a primary connection 5 and a secondary connection 6 .

[0037] During operation of the pressure regulating valve 1 , compressed air is supplied via the primary connection 5 at the primary pressure, which is regulated to the secondary pressure while flowing through the regulator housing 2 and is at this The ground under the secondary pressure can be tapped off at the secondary connection 6 . In general, the secondary pressure is lower than the primary pressure and its height can be predetermined as required by a corresponding adjustment of the pressure regulating valve 1 .

[0038] The primary channel 3 and the secondary channel 4 are connected to one another through an overflow open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com