Relay and contact system thereof

A technology of relays and contacts, applied in relays, electromagnetic relays, contacts, etc., can solve the problems of violent material heating, adhesion, contact point welding, etc., and achieve the purpose of increasing the electric cross-sectional area, reducing contact welding, and reducing temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings. It can be understood that the drawings are provided for reference and illustration only, and are not intended to limit the present invention. The dimensions shown in the drawings are only for the convenience of clear description, and do not limit the proportional relationship.

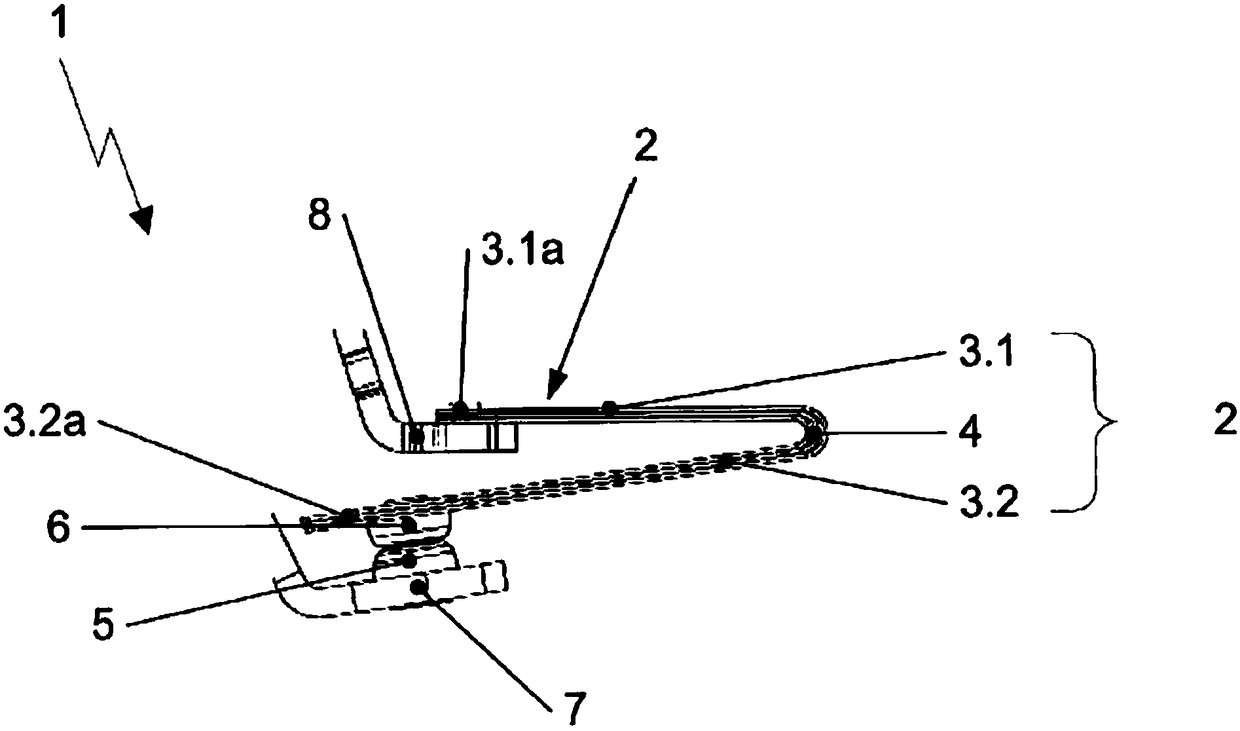

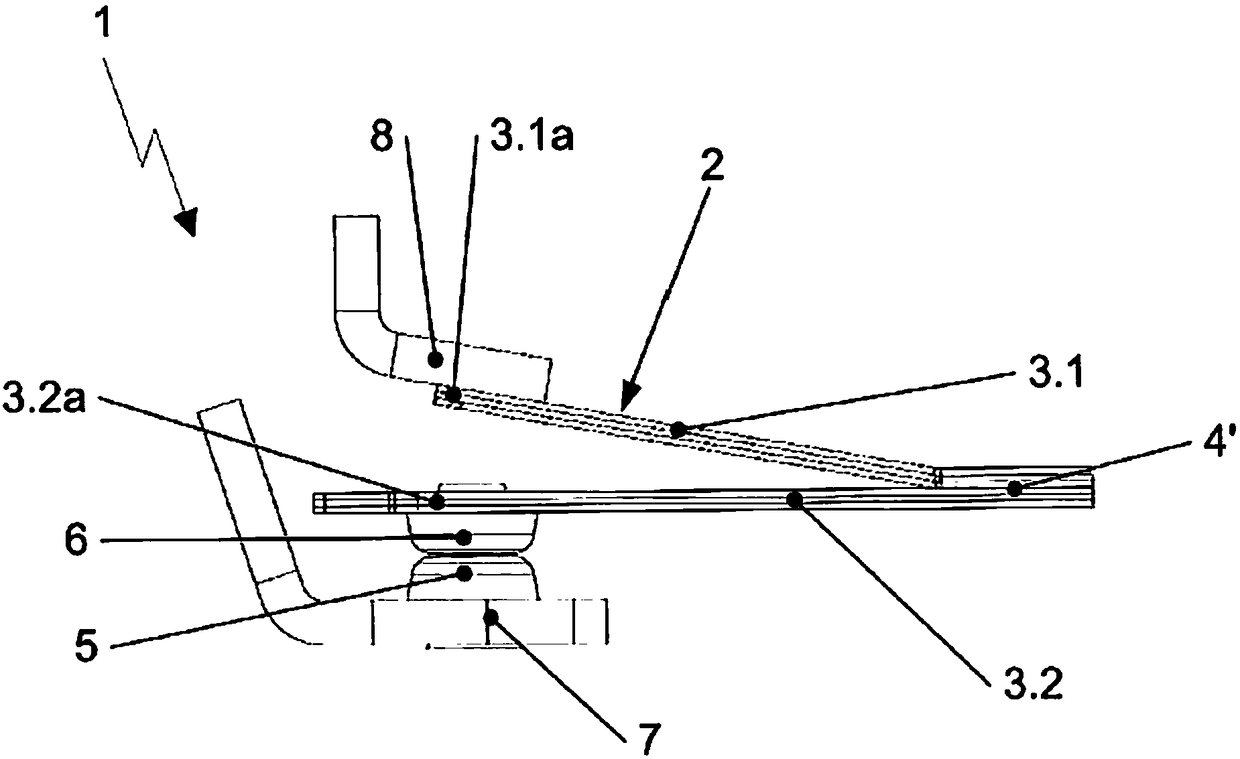

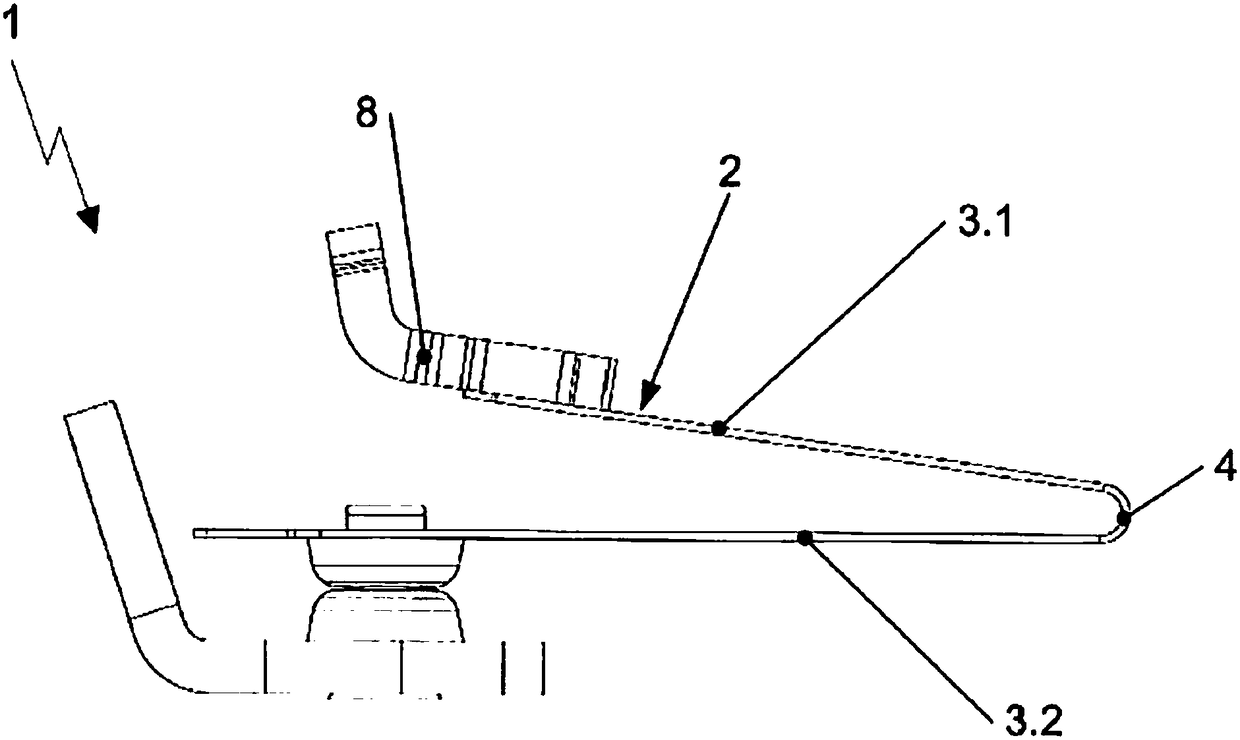

[0033] Please refer to Figure 1A , Figure 1A The contact system 1 of an off relay using a substantially V-shaped contact carrier 2 is shown. Wherein, the V-shaped contact bracket 2 includes two spring arms 3.1, 3.2, and the first upper spring arm 3.1 and the second lower spring arm 3.2 are connected to each other through a rounded connecting portion 4 . The contact system 1 serves to switch the contact between a first stationary fixed contact part 5 and a second mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com