Solar panel cleaning determination method for solar photovoltaic power generation system

A solar panel and solar photovoltaic technology, applied in the field of solar photovoltaic power generation systems, can solve problems such as inability to determine the cleaning of photovoltaic modules, and achieve the effects of dynamic cleaning and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

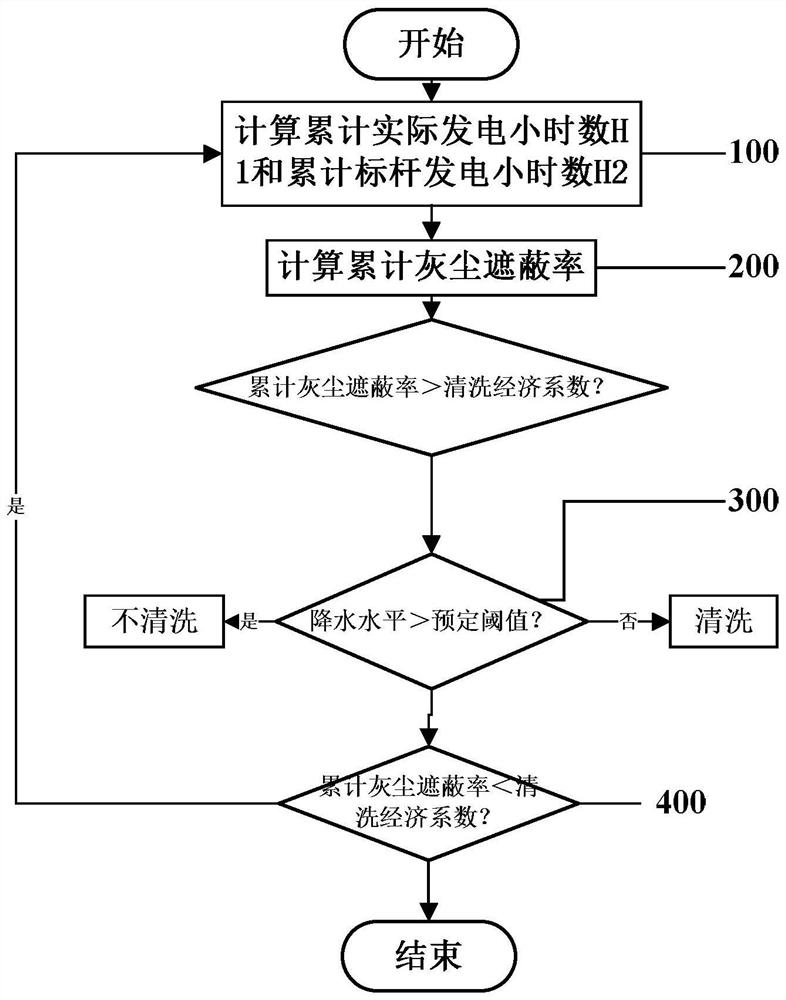

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as figure 1 The illustrated embodiment is a method for judging solar panel cleaning in a solar photovoltaic power generation system, including a power station in which 20 5KW inverters and 27,936 315w solar panels are arranged; the 27,936 solar panels are divided into 20 groups, Each inverter is electrically connected to 27936 / 20 solar panels, and one inverter is set as a benchmark inverter, and each solar panel connected to the benchmark inverter is cleaned daily; including the following steps: setting Set the time T1 when all solar panels were cleaned last time to be 30 days ago;

[0025] Step 100, calculating the cumulative actual power generation hours H1 and the cumulative benchmark power generation hours H2 from T1 to the current moment;

[0026] H1=901800kwh / 8800KW=102.447h from T1 to the current moment, H2=533kwh / 5KW=106.6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap