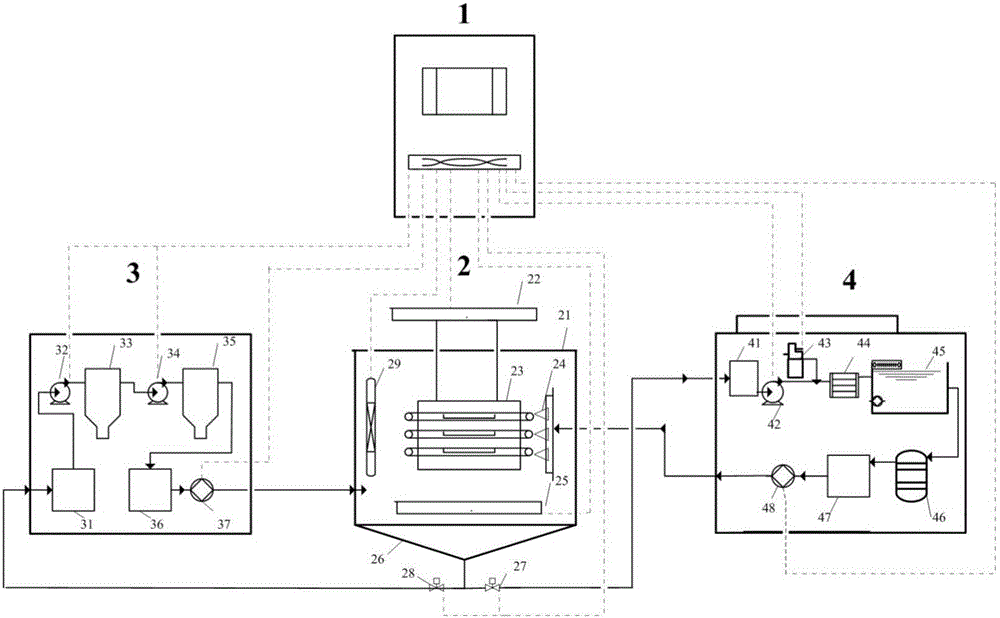

Cleaning device and method for simulated rock core used in laboratory experiment of microbial flooding physical simulation

A technology of microbial flooding and simulating cores, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. Cleaning efficiency and cleaning effect, avoiding environmental pollution, and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Utilize the present invention to carry out one-time automatic cleaning to three groups of simulated rock cores in the physical simulation experiment of microbial oil displacement, and the specific steps are as follows:

[0050] (1) Preliminary preparation stage

[0051] First remove the plugs at both ends of the 3 sets of experimental simulated cores, use the simulated core removal device to remove the quartz sand and crude oil in the simulated cores, fix the simulated cores on the simulated core holder, and the distance between the jet nozzle and the right opening of the simulated core 0.5cm, close the top cover of the immersion cleaning tank.

[0052] (2) Static soaking stage

[0053] Turn on the circulation pump and pump the petroleum ether in the cleaning agent storage tank into the immersion cleaning pool at a constant speed. The liquid level of petroleum ether in the immersion cleaning pool is 15cm. The time is 10 minutes.

[0054] (3) Shock soaking stage

[0...

Embodiment 2

[0063] Using the present invention to carry out one-time automatic cleaning of 6 groups of simulated rock cores in the physical simulation experiment of microbial oil displacement, the specific steps are as follows:

[0064] (1) Preliminary preparation stage

[0065] First remove the plugs at both ends of the 6 groups of experimental simulated cores, use the simulated core removal device to remove the quartz sand and crude oil in the simulated cores, fix the simulated cores on the simulated core holding device, and the distance between the jet nozzle and the right opening of the simulated core 1.0cm, close the top cover of the immersion cleaning tank.

[0066] (2) Static soaking stage

[0067] Turn on the circulation pump and pump the petroleum ether in the cleaning agent storage tank into the immersion cleaning pool at a constant speed. The liquid level of petroleum ether in the immersion cleaning pool is 20cm. The time is 15 minutes.

[0068] (3) Shock soaking stage

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap