Self-assembled nanostructures and separation membranes comprising aquaporin water channels and methods of making and using them

A technology of aquaporin and nanostructure, which is applied in the field of self-assembled nanostructures, and can solve problems such as difficulty in controlling the size of vesicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

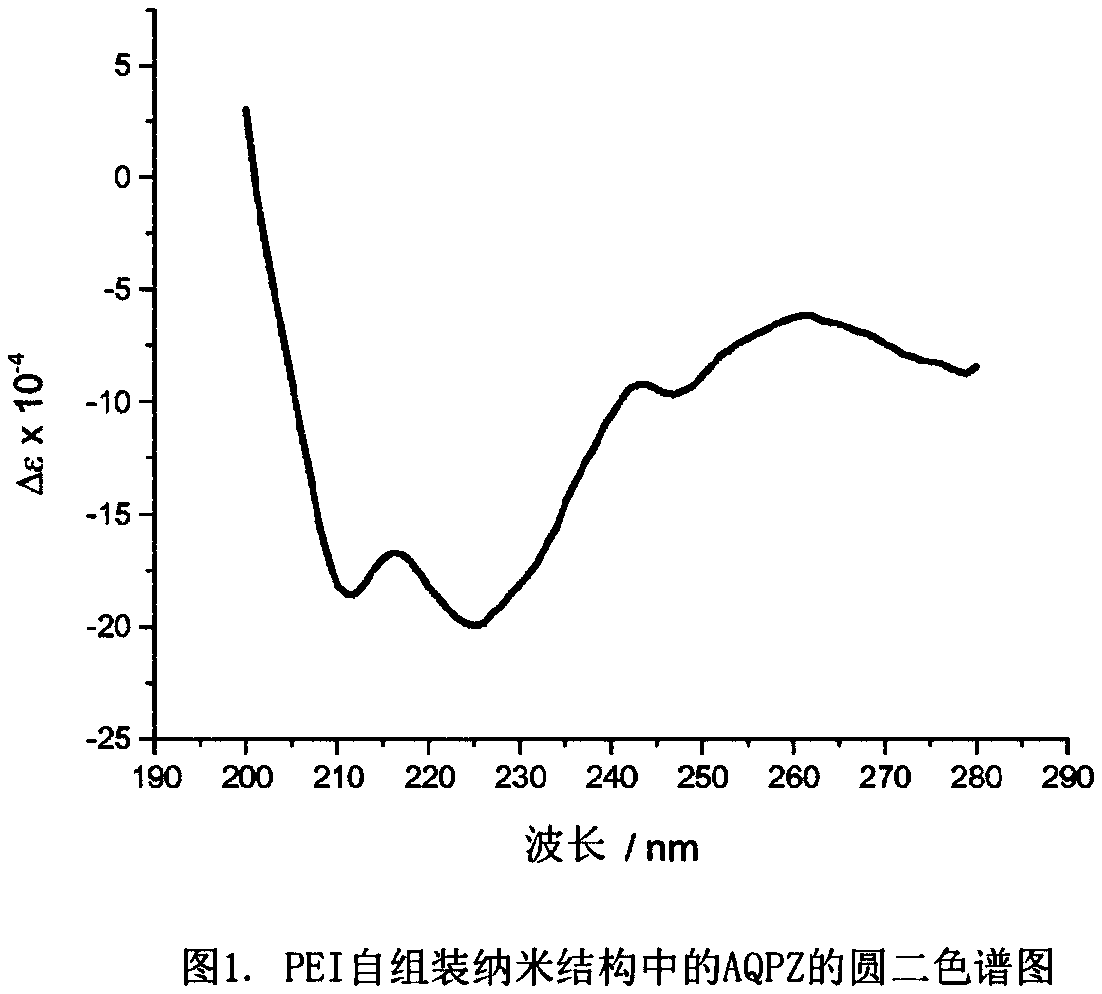

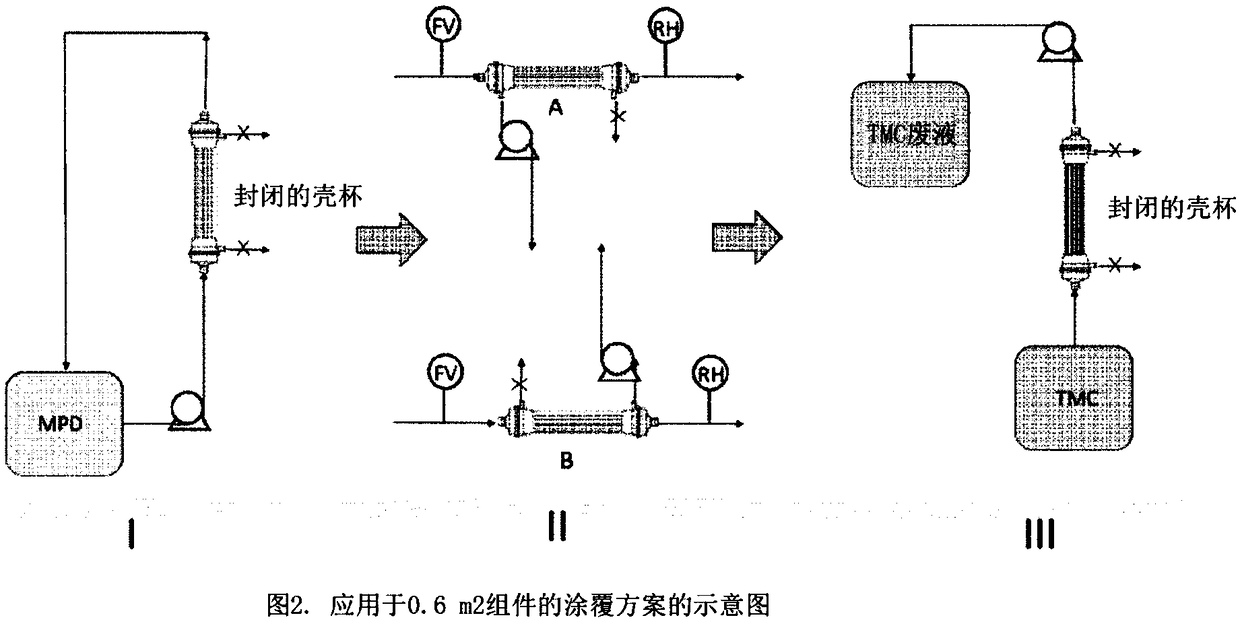

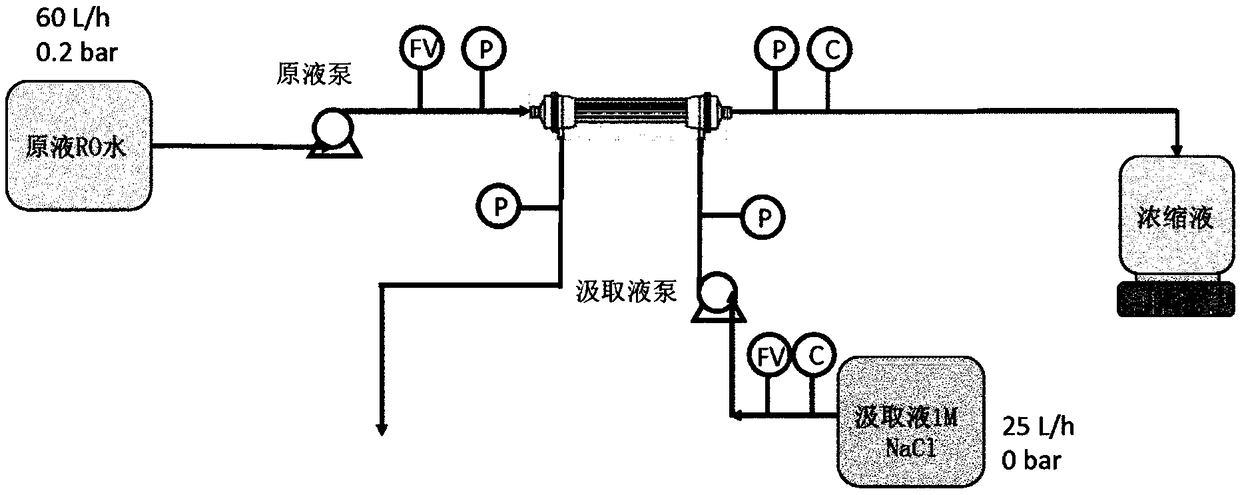

[0100] Preparation of Example 1.PEI-Aquaporin-Z Nanoparticles and Stopped Flow Testing (Stopped FlowTesting)

[0101] m W Poly(ethyleneimine) (linear) (PEI) of 4000 Da was purchased from Sigma Aldrich and used without any other purification. By adding 8g NaCl, 0.2g KCl, 1.44g Na 2 HPO 4 and 0.24g of KH 2 PO 4 Dissolve in 800 mL MilliQ purified HO 2 A 10 mM phosphate solution (PBS) (pH 7.2, 136 mM NaCl, 2.6 mM KCl) was prepared by adjusting the pH to 7.2 with HCl in 0 and bringing the volume up to 1 L. N,N-Dimethyldodecylamine N-oxide BioXtra (lauryldimethylamine N-oxide) (99% purity), LDAO was purchased from Sigma Aldrich.

[0102] The PEI-based self-assembled structures were prepared by a direct dissolution method. First, 100 ml of 5 mg / mL PEI in phosphate buffer at pH 7.2 was prepared by dissolving 500 mg of PEI powder in 100 mL of PBS at pH 7.2. Further, 100 mL of 5 mg / mL PEI was directly mixed with 1.5 mg of aquaporin Z (AQPZ) (0.3 mL from a purified stock solution...

Embodiment 2

[0115] Example 2. Preparation and testing of PEI nanostructures with AQP9 and AQP12

[0116] In a similar manner, PEI-based self-assembled structures containing human aquaporins, more specifically aquaporin-9 and aquaporin-012, were prepared by the direct dissolution method. First, 100 ml of 5 mg / mL PEI in phosphate buffer at pH 7.2 was prepared by dissolving 500 mg of PEI powder in 100 mL of PBS at pH 7.2. Further, 100 mL of 5 mg / mL PEI was mixed with 1.5 mg aquaporin-9 (0.15 mL from a purified stock solution of 10 mg / mL aquaporin-9 in 2% LDAO) and aquaporin-12 (from 9 mg / mL mL of aquaporin-12 was directly mixed with 0.17 mL of the purified stock solution in 2% LDAO, corresponding to a two-component mixture at a molar ratio of 1 / 800 AQP / PEI. The PEI-AQP mixture was stirred overnight at 170 rpm for no more than 20 hours (but not less than 12 hours).

[0117] After stirring, the mixture was transferred to a 100 mL glass bottle the next day, kept at room temperature, and measu...

Embodiment 3

[0122] Example 3. Fabrication and testing of nanostructures with PEI 800b and 1000b

[0123] In a similar manner, PEI 4000 Da self-assembled structures containing AQPZ, and 800-branched and 1000-branched PEI were prepared by the direct solution method. First, prepare 100 ml of 5 mg / mL phosphate salts of 800-branched and 1000-branched PEI at pH 7.2 by dissolving 500 mg of 800-branched and 1000-branched PEI powder in 100 mL of PBS at pH 7.2 buffer. Further, 100 mL of 5 mg / mL PEI was directly mixed with 1.5 mg of AqpZ (0.3 mL from a purified stock solution of 5 mg / mL AqpZ in 2% LDAO), corresponding to a two-component mixture at a molar ratio of 1 / 800 AQP / PEI . The PEIAQP mixture was stirred overnight at 170 rpm for no more than 20 hours (but not less than 12 hours).

[0124] After stirring, the mixture was transferred to a 100 mL glass bottle the next day, kept at room temperature, and measured the next day. The size and permeability of the PEI-AQPZ self-assembled structures ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com