A method for forming a battery wrap film, a battery pack, and an electronic device

An electronic equipment and wrapping technology, applied in the field of battery components and electronic equipment, and the formation of battery wrapping films, can solve the problems of low reliability, poor wrapping effect, weak adhesion, etc., and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

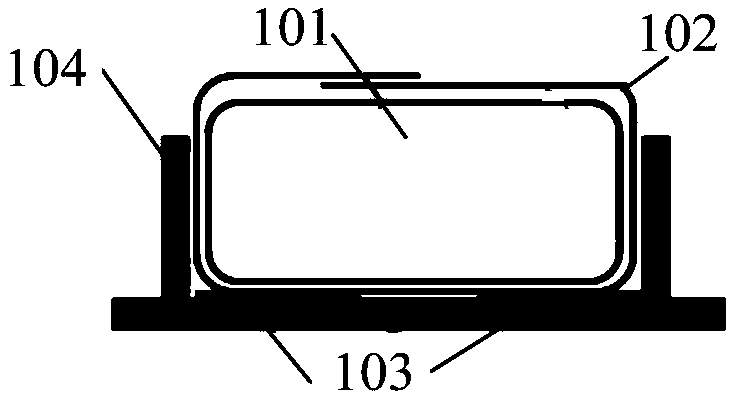

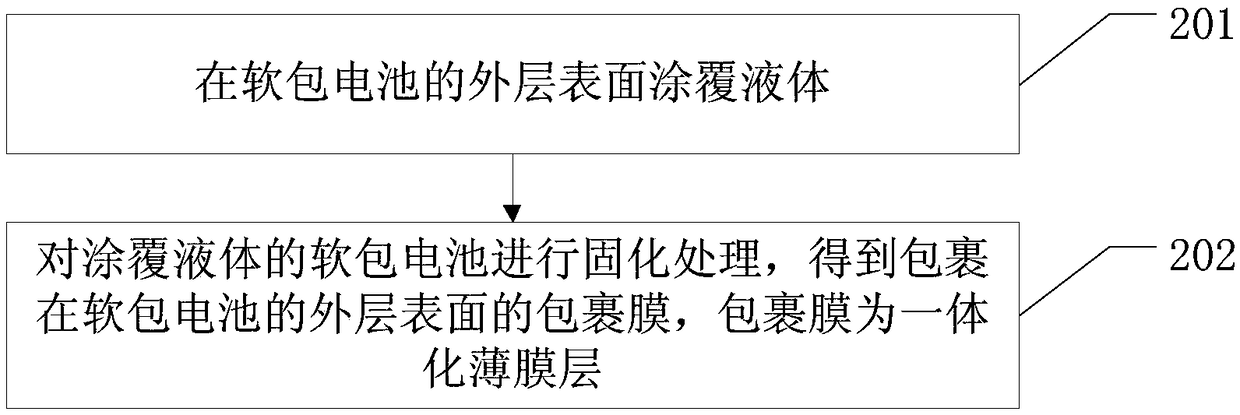

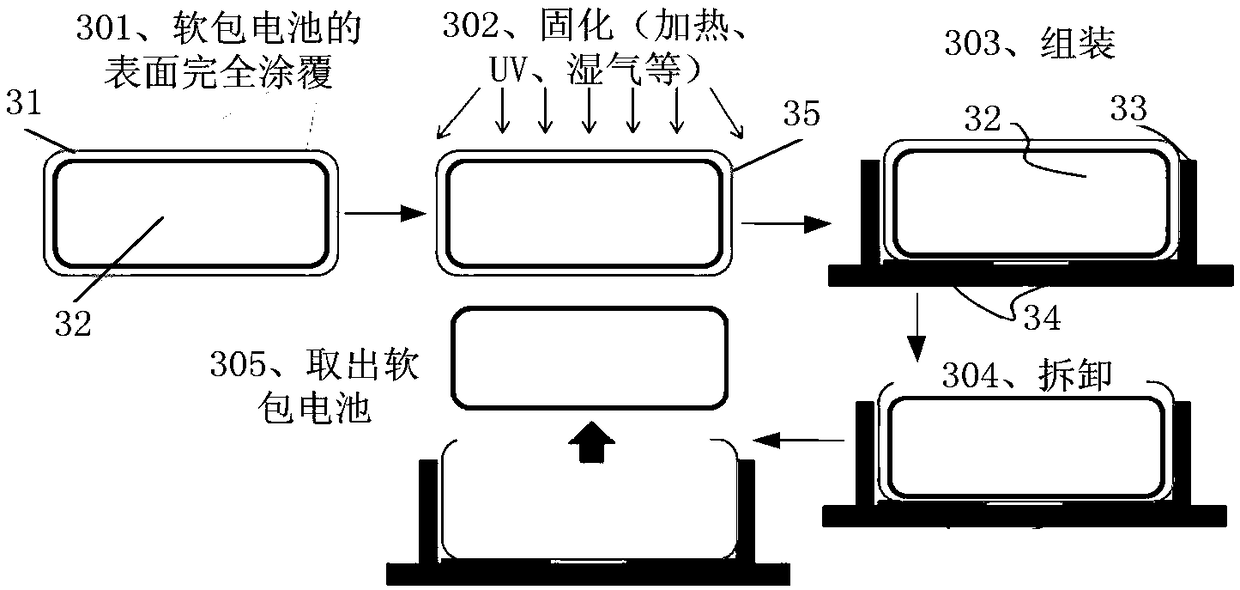

[0024] In order to solve the problems in the prior art that the adhesion between the wrapping film and the outer surface of the pouch battery is weak, the wrapping effect is poor and the reliability is low, and the wrapping film makes it difficult to disassemble the pouch battery, this application implements The example provides a method for forming a battery wrapping film. A liquid is coated on the outer surface of a pouch battery, and the pouch battery coated with the liquid is cured to form a wrapping film after the liquid is cured, and the wrapping film is integrated. The thin film layer can form a better integrated adhesion effect with the outer surface of the pouch battery, and the reliability is high, and when the pouch battery is installed in the battery compartment through the sticky substance pasted on the wrapping film , The wrapping film isolates the pouch battery from the sticky matter. Since the wrapping film is thin, it is easy to peel off the wrapping film and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com