Reinforcing method for building energy-saving floor slab

A building energy-saving and floor slab technology, which is applied in the direction of floors, buildings, building components, etc., can solve problems such as cracks and looseness, and achieve the effects of improving fluidity, reducing segregation, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

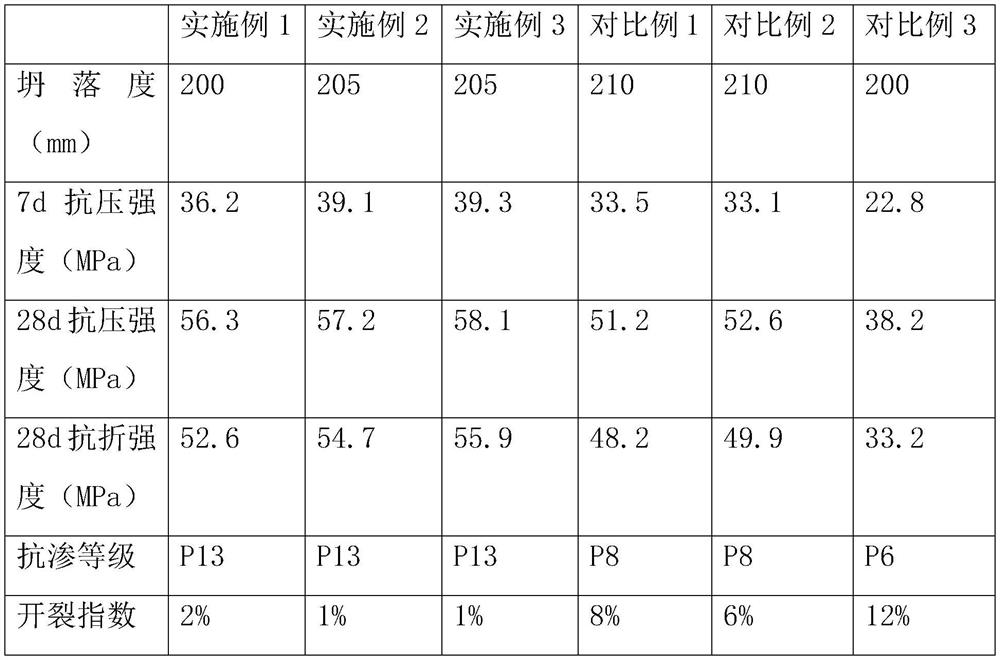

Examples

Embodiment 1

[0036] A reinforcement method for building energy-saving floor slabs, comprising the following steps:

[0037] Step 1, prepare the soaking solution by mixing polyether-modified siloxane and water according to the mass ratio of 1:0.1, and immerse the building energy-saving floor slab in the soaking solution for 5 minutes;

[0038] Step 2, laying building energy-saving floor slabs according to the design drawings;

[0039] Step 3, paving concrete slurry on the surface of the building energy-saving floor slab for reinforcement, curing to form a concrete surface layer, the thickness of the concrete surface layer is 5cm.

[0040] The mass ratio of cement, sand, stone, water and bagasse fiber in each cubic meter of concrete slurry is 13:28:40:6:13, mix the cement, sand, stone, water and bagasse fiber in the above mass ratio , stirring at a rotating speed of 30r / min for 10min, and stirring evenly to obtain concrete slurry.

[0041] The preparation method of the bagasse fiber is as ...

Embodiment 2

[0043] A reinforcement method for building energy-saving floor slabs, comprising the following steps:

[0044] Step 1, prepare the soaking solution by mixing polyether-modified siloxane and water according to the mass ratio of 1:8, and immerse the building energy-saving floor slab in the soaking solution for 8 minutes;

[0045] Step 2, laying building energy-saving floor slabs according to the design drawings;

[0046] Step 3, paving concrete slurry on the surface of the building energy-saving floor slab for reinforcement, curing to form a concrete surface layer, the thickness of the concrete surface layer is 5cm.

[0047] The mass ratio of cement, sand, stone, water and bagasse fiber in each cubic meter of concrete slurry is 15:26:41:7:11, mix the cement, sand, stone, water and bagasse fiber in the above mass ratio , stirring at a rotating speed of 30r / min for 10min, and stirring evenly to obtain concrete slurry.

[0048] The preparation method of the bagasse fiber is as fo...

Embodiment 3

[0050] A reinforcement method for building energy-saving floor slabs, comprising the following steps:

[0051] Step 1, prepare the soaking solution by mixing polyether-modified siloxane and water according to the mass ratio of 1:10, and immerse the building energy-saving floor slab in the soaking solution for 10 minutes;

[0052] Step 2, laying building energy-saving floor slabs according to the design drawings;

[0053] Step 3, paving concrete slurry on the surface of the building energy-saving floor slab for reinforcement, curing to form a concrete surface layer, the thickness of the concrete surface layer is 5cm.

[0054]The mass ratio of cement, sand, stone, water and bagasse fiber in each cubic meter of concrete slurry is 16:24:44:8:8, mix the cement, sand, stone, water and bagasse fiber in the above mass ratio , stirring at a rotating speed of 30r / min for 10min, and stirring evenly to obtain concrete slurry.

[0055] The preparation method of the bagasse fiber is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com