Pulley gear for heel as well as roller skate and roller shoe with pulley gear

A pulley and heel technology, which is applied to footwear, skating, shoe soles, etc., can solve problems such as high manufacturing precision requirements, shedding necrosis, and potential safety hazards, and achieves a combination that ensures stability, reduces impact side effects, and has reliable and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

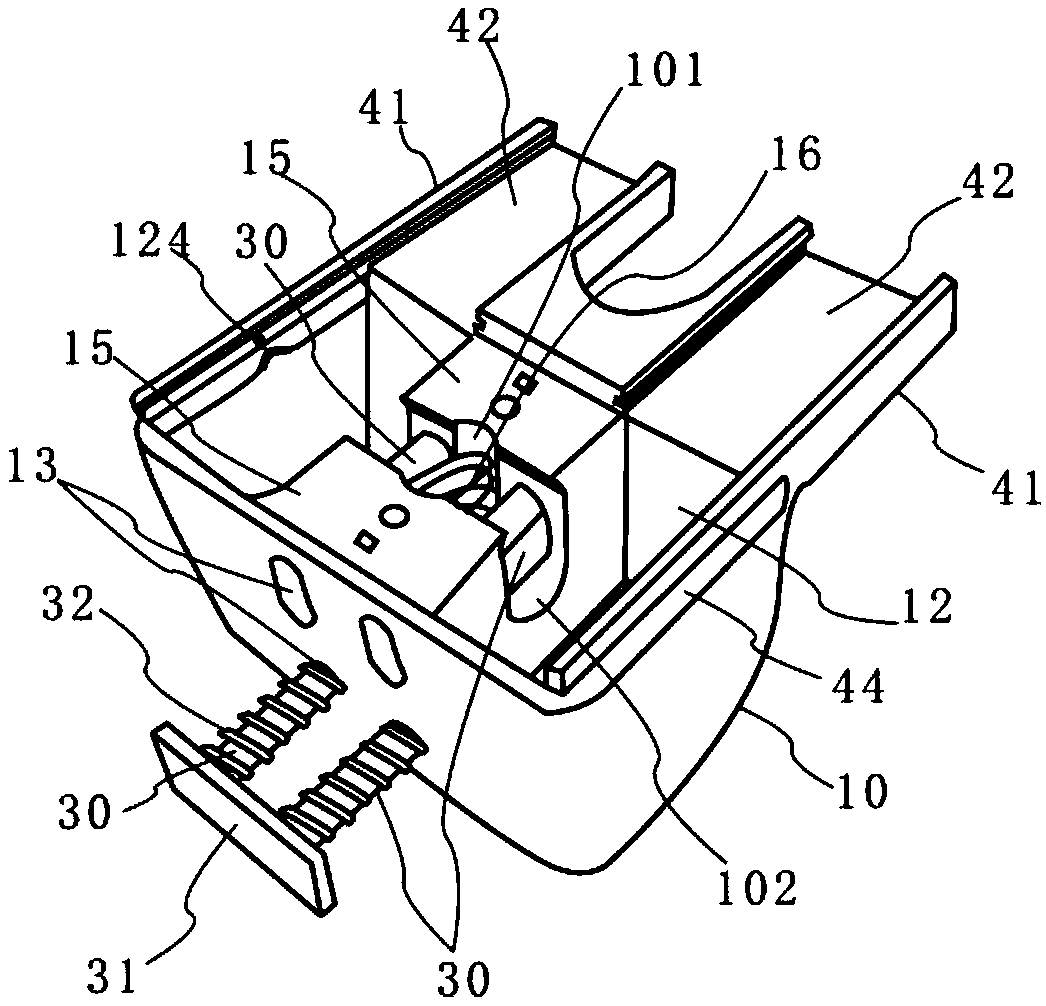

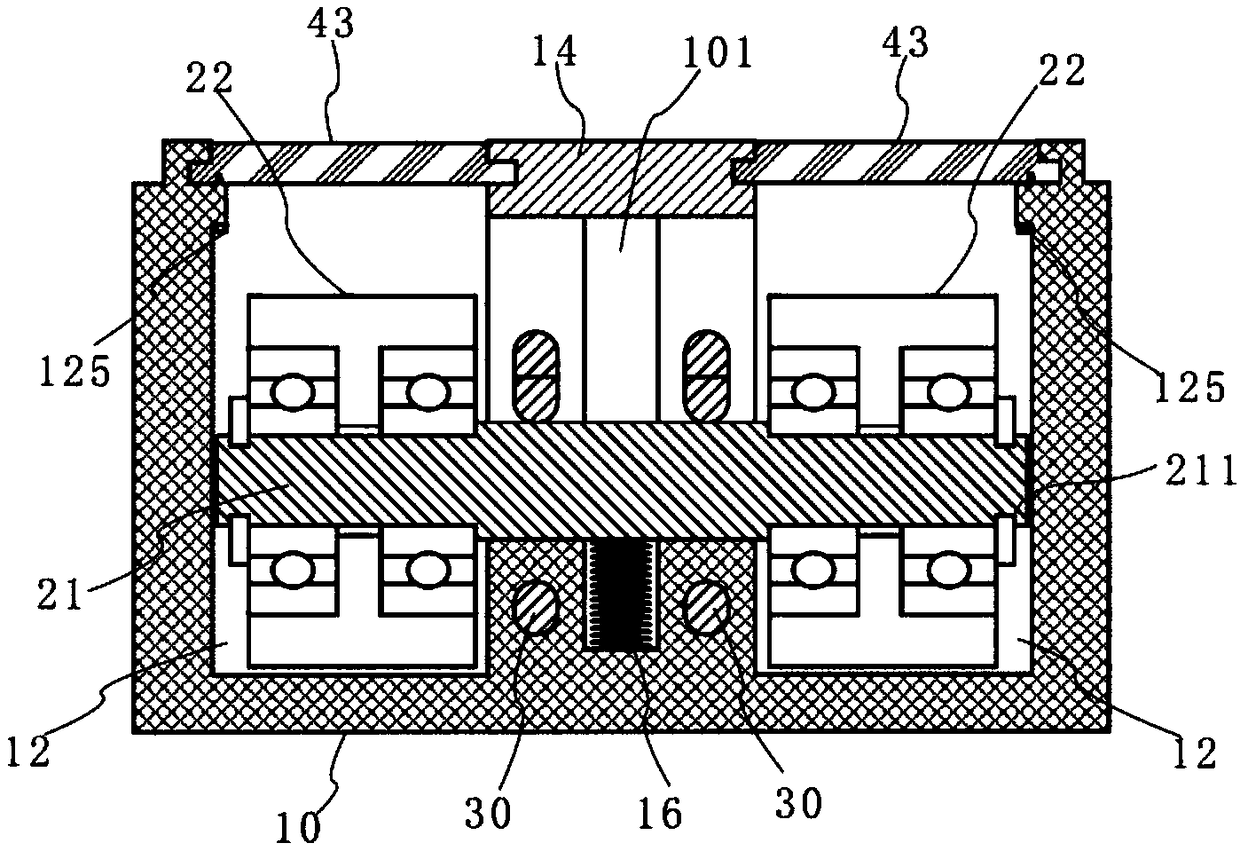

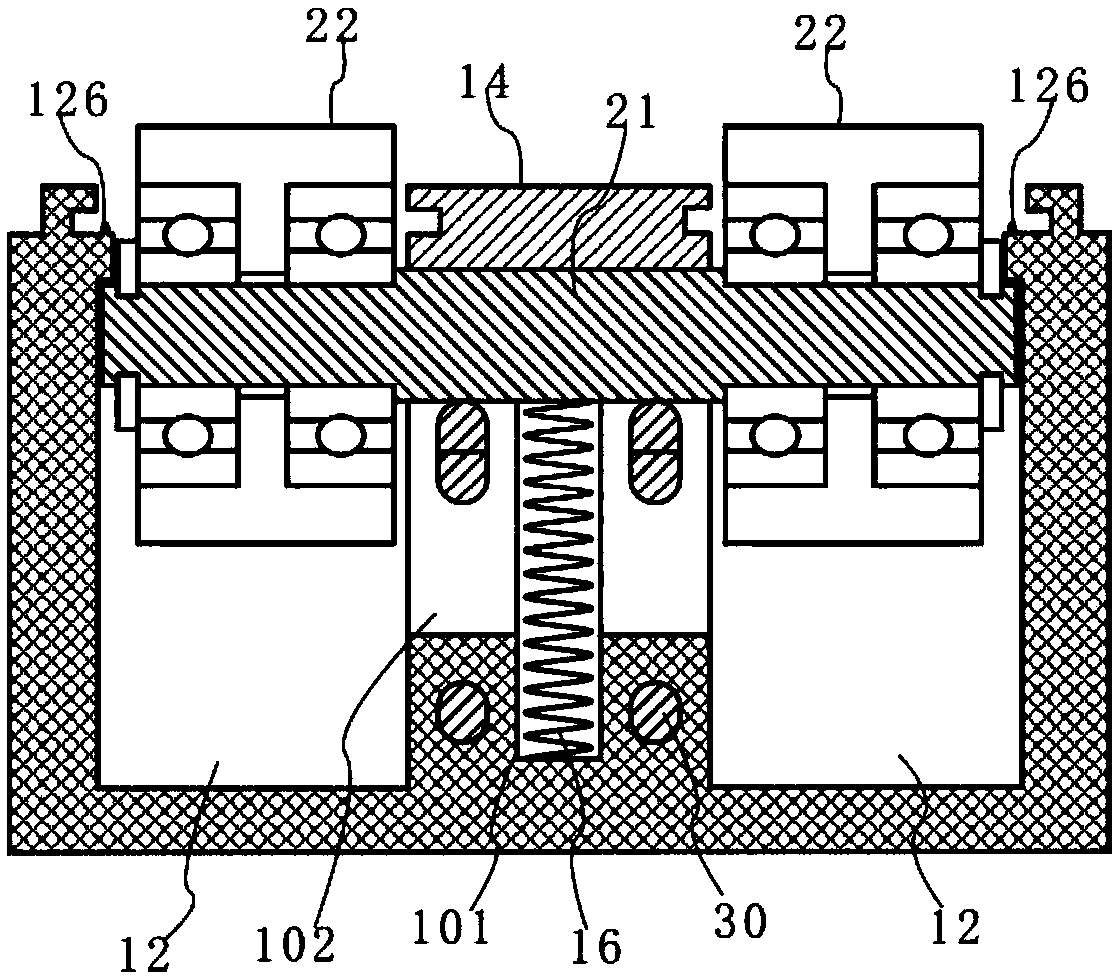

[0041] like Figure 1-8 As shown, the present embodiment provides a pulley device for a heel, and the pulley device 100 includes a pulley seat 10 , a pulley assembly 20 and two U-shaped blocking bars 30 .

[0042] In this embodiment, the pulley assembly 20 includes a pulley shaft 21 and two pulley bodies 22 respectively axially fixed and circumferentially rotatable arranged on the pulley shaft 21, wherein the axial ends of the pulley shaft 21 Each has a reduced diameter ring 211 and an enlarged diameter section 212 in the axial middle, and the axial length between the end of the expanded diameter section 212 and the reduced diameter ring 211 on the same side is equivalent to the axial width of the pulley body 22 . The central shaft hole of the pulley body 22 is divided into two installation cavities by a spacer, and rolling bearings are respectively pressed in each installation cavity. The rolling bearing abuts against the snap spring 213 fixed in the diameter reducing ring 2...

Embodiment 2

[0054] like Figure 1-10 As shown, this embodiment provides a walking shoe, including a sole body 200 and the pulley device 100 described in the first embodiment above, the pulley device 100 is installed on the heel of the sole body 200, and the bottom surface of the cover 14 On the same level as the bottom surface of the sole body 200, the rear side of the sole body 200 is provided with a mounting hole and a pressing block 201 movably inserted in the mounting hole, and the pressing block 201 is connected with the connecting plate 31, specifically The pressing block 201 is composed of a pressing part movably penetrated in the mounting hole and a limiting part connected to the front end of the pressing part and unable to pass through the mounting hole. The limiting part is connected with the connecting plate 31, and by pressing the The pressing block 201 can make the U-shaped bar 30 move backward to open the communication slot to facilitate the adjustment of the pulley assembly...

Embodiment 3

[0056] like Figure 1-8 , 11-14, this embodiment provides a roller skate, including a sole body 200, a front wheel device 500 and the pulley device 100 described in the first embodiment above.

[0057] The pulley device 100 is installed on the heel of the sole body 200, and the bottom surface of the cover 14 is on the same level as the bottom surface of the sole body 200. The rear side of the sole body 200 is provided with a mounting hole and is movably inserted in the mounting hole. The pressing block 201 inside, the pressing block 201 is connected with the connecting plate 31, specifically, the pressing block 201 is formed by a pressing part which is movable through the mounting hole and connected to the front end of the pressing part and cannot pass through the mounting hole. The limiting part is composed of a limiting part, the limiting part is connected with the connecting plate 31, and the U-shaped bar 30 can be moved backward by pressing the pressing block 201 to open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com