Air-coupled capacitive micromachined ultrasonic transducer, preparation method and use

A capacitive micro-machining, ultrasonic transducer technology, applied in chemical instruments and methods, vacuum evaporation coating, fluid using vibration, etc., can solve the problems of slow detection speed, etc. The effect of deflection control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

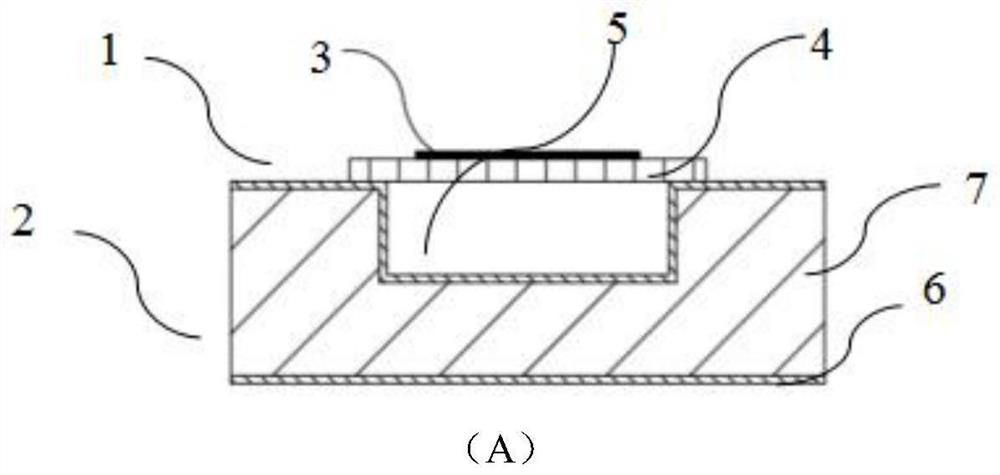

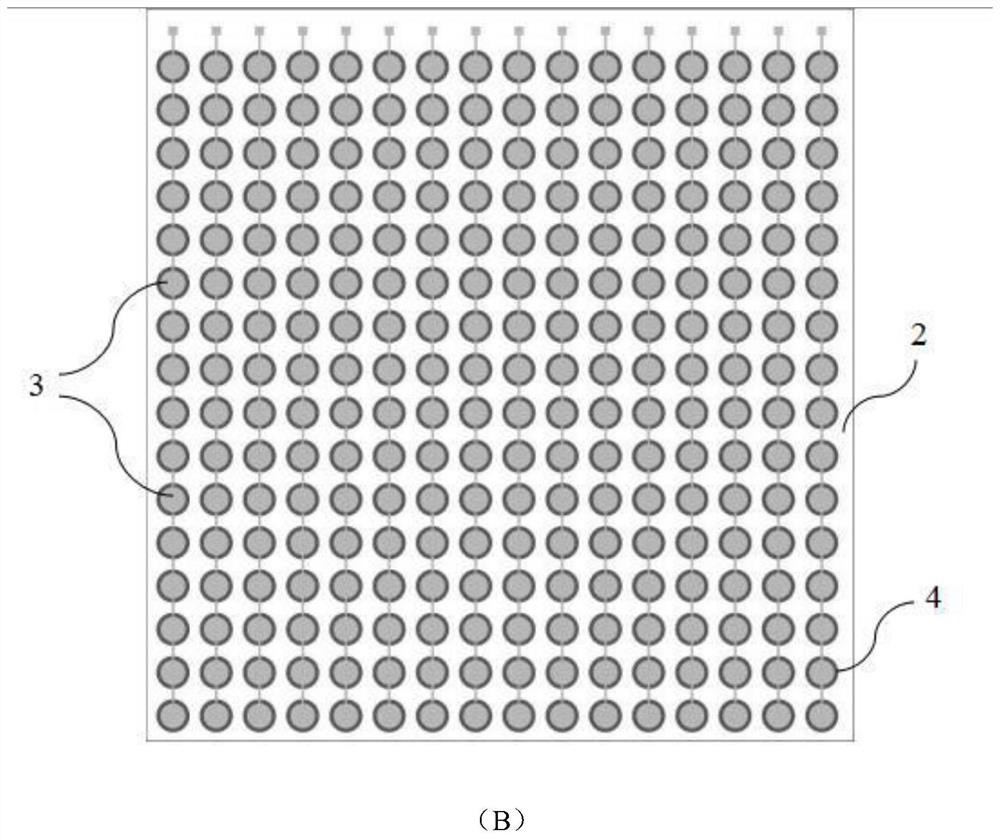

[0048] The purpose of the embodiment of the present invention is to provide a capacitive micro-ultrasonic transducer for ultrasonic nondestructive testing applied to air coupling. The transducer is composed of 16 array elements, and each array element is composed of multiple sensitive elements. See figure 2 (A).

[0049] The structure of each sensitive element is composed from top to bottom: upper electrode 3, diaphragm 1, cavity 5, and base 2 (wherein, base 2 is also used as the lower electrode), see figure 2 (B).

[0050] There is a cavity 5 between the diaphragm 1 and the base 2, which constitutes a capacitor, and a DC voltage is pre-loaded between the upper electrode 3 and the lower electrode 2, so that an electrostatic field is formed in the capacitor, and the diaphragm 1 under the action of the electric field force Deformation occurs under the diaphragm, thereby forming a pre-tightening force in the diaphragm 1, and the diaphragm 1 is in a stable equilibrium state.

...

Embodiment 2

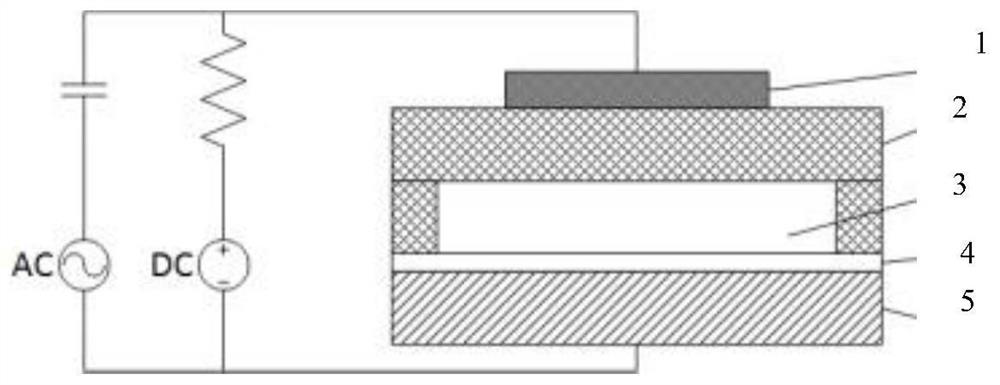

[0054] Combine below figure 1 The scheme in Example 1 is further introduced, see the following description for details:

[0055] The overall structure of the embodiment of the present invention consists of two parts, the vibrating membrane 1 and the base 2 . The vibrating membrane 1 is composed of an upper electrode 3 and a thin film 4 .

[0056] In specific implementation, the thin film 4 may be a single crystal silicon thin film. It may also be set according to requirements in practical applications, which is not limited in this embodiment of the present invention.

[0057] Wherein, the material of the upper electrode 3 can be selected from gold, aluminum and the like. In the embodiment of the present invention, a single crystal silicon thin film is used as a component of the vibrating membrane 1 and the ultrasonic receiving sensitive element.

[0058] The base 2 is jointly formed by a cavity 5 and an insulating layer 6 . The material of the insulating layer 6 is silico...

Embodiment 3

[0061] see figure 2 (B), the embodiment of the present invention provides a preparation method of an air-coupled ultrasonic transducer, the preparation method is corresponding to the air-coupled ultrasonic transducer in Examples 1 and 2, and the preparation method includes:

[0062] The SOI wafer bonding technology adopted in the embodiment of the present invention is a bulk silicon process. This technology overcomes the defect of using a sacrificial layer, and processes a larger unit size through deep etching of the silicon base material, and has high processing reliability. The process flow of SOI wafer bonding process is as follows:

[0063] (A) Prepare silicon substrate 2, what silicon substrate 2 adopts is doped low-resistance silicon, thereby can form parallel plate capacitance with top electrode;

[0064] (B) Reactive ion etching (RIE) or wet etching is used to etch a cavity 5 with a target depth at a desired position, and the depth of the cavity 5 is 5 μm;

[0065]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com