Extruding machine

A technology of extruders and moving beams, applied in the field of extruders, can solve the problems of increasing manufacturing costs, achieve the effects of reducing processing accuracy, reducing replacement frequency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

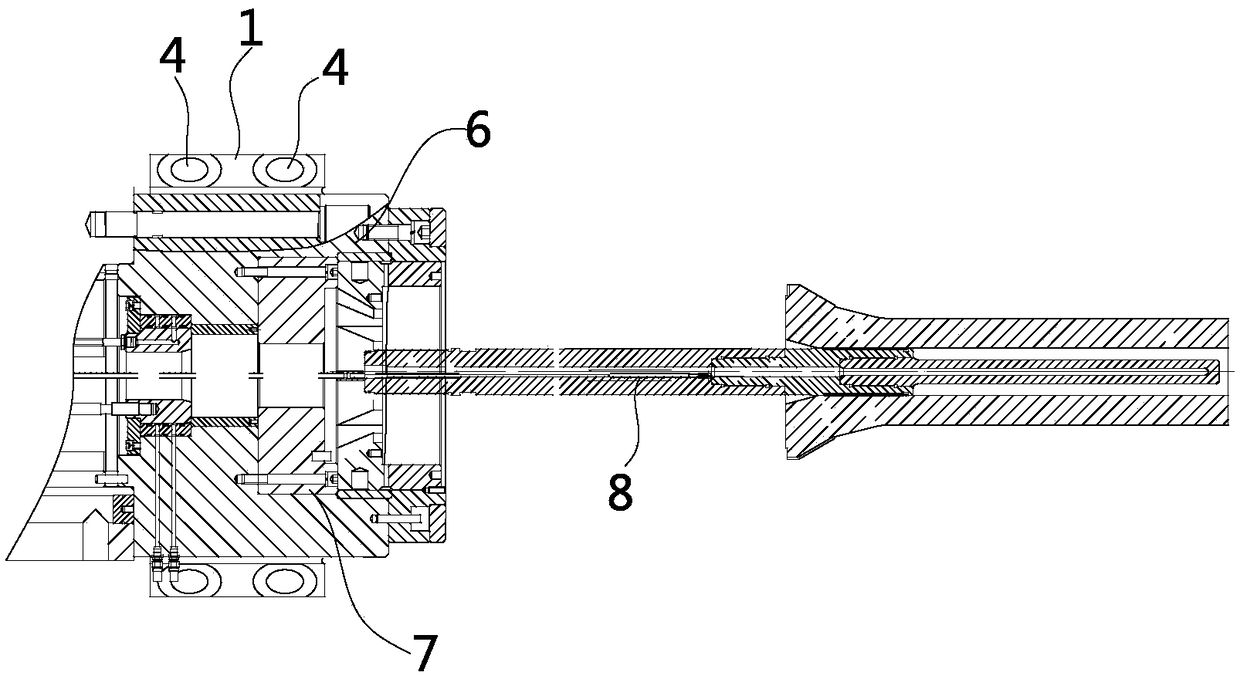

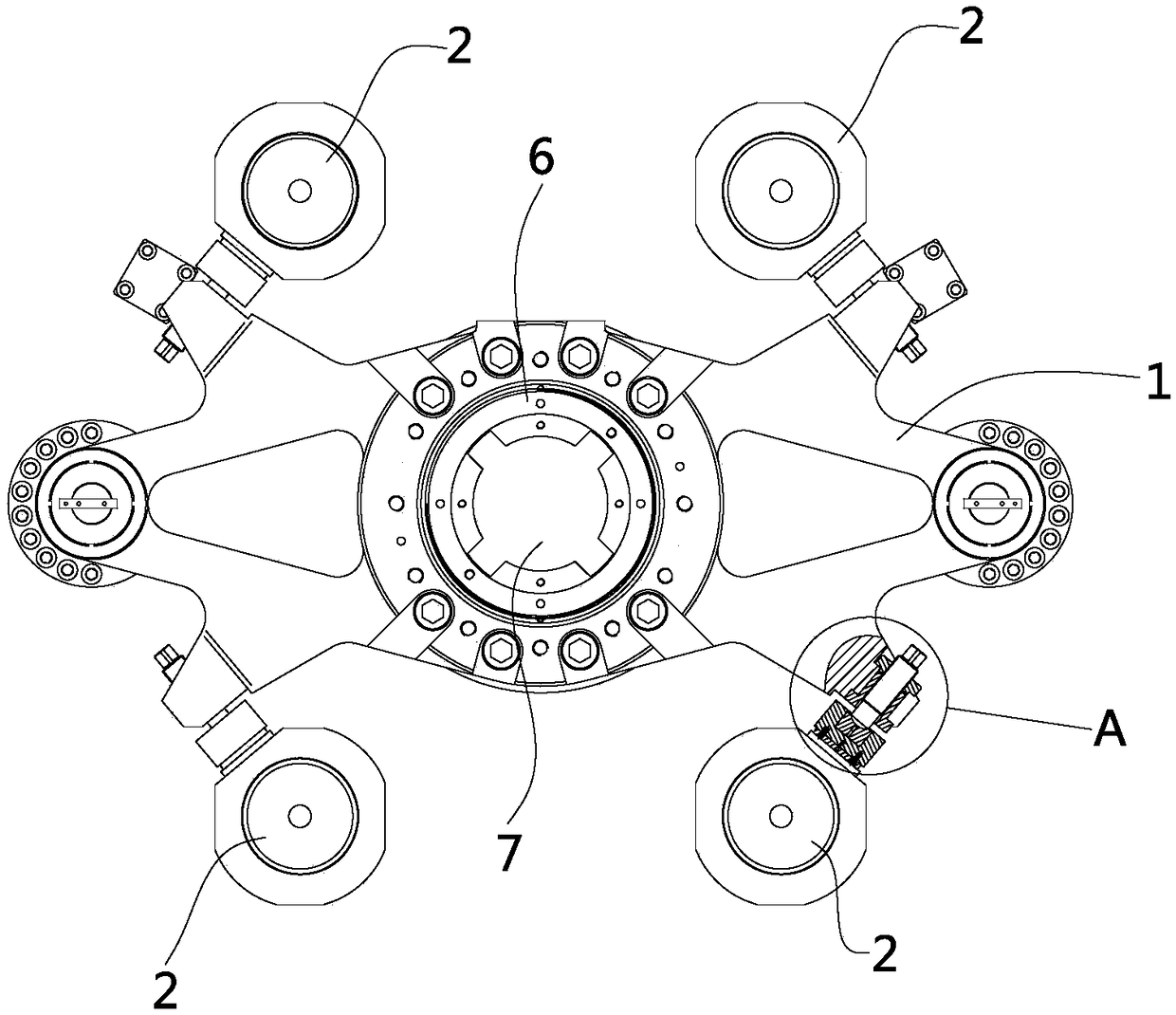

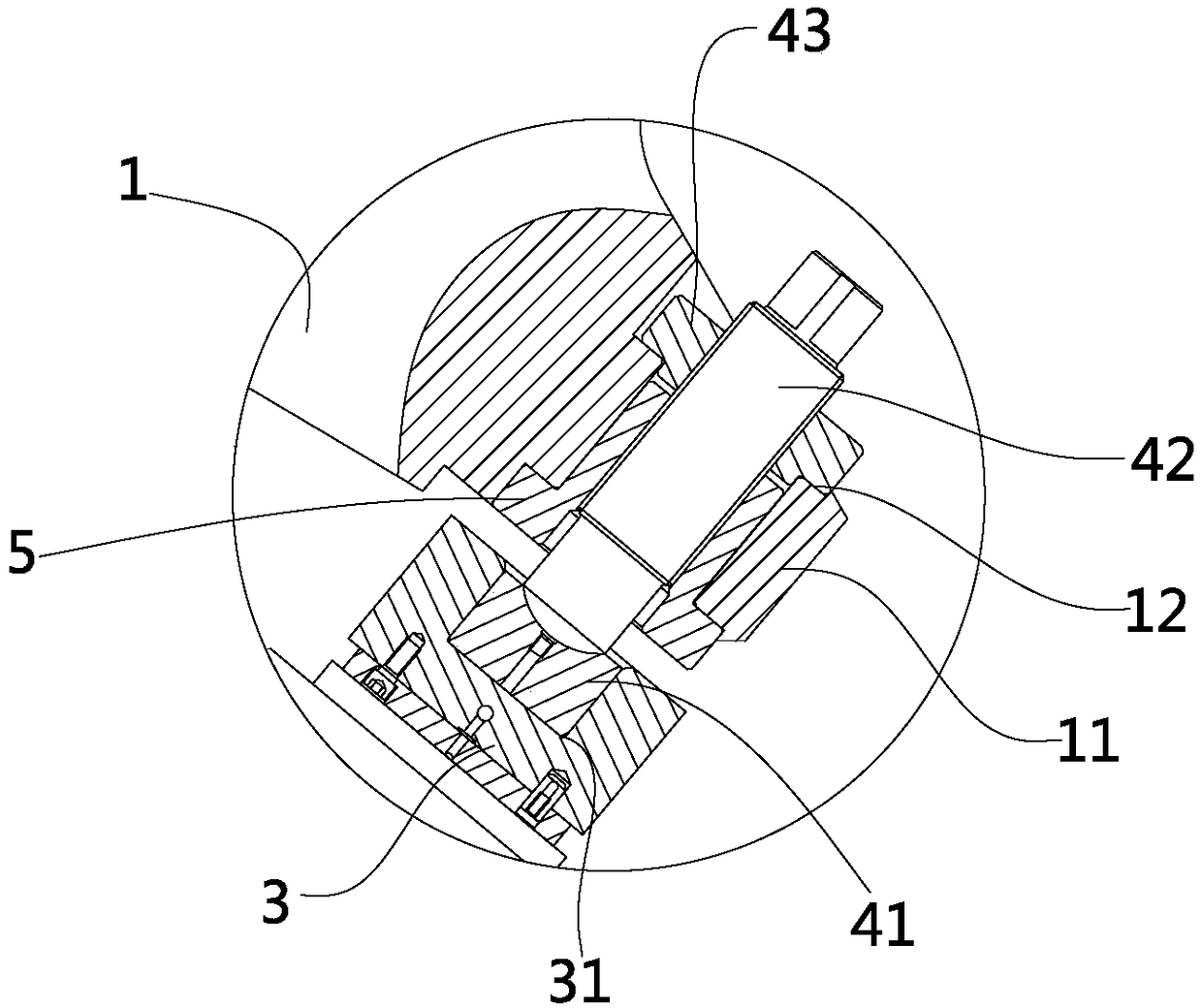

[0025] The invention discloses an extrusion machine, which comprises a rear beam, a moving beam and a front beam, four upright columns are installed between the back beam and the front beam, the moving beam is slidably installed on the four upright columns, and the back beam There is a main oil cylinder for driving the moving beam to reciprocate axially on the column, the column is provided with a slide plate axially arranged, the slide plate is provided with a chute, and the moving beam is set There are four installation bosses distributed diagonally, and two adjustment mechanisms distributed front and rear are arranged on the installation bosses. The adjustment mechanisms include sliders, adjustment screws and lock nuts. The sliders are slidably installed In the chute, the adjusting screw is threadedly connected to the mounting boss and locked and fixed by the locking nut, and one end of the adjusting screw is rotatably matched with the sliding block.

[0026] When adjusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com