A butt joint device of a single rivet clamp automatic assembly machine

A docking device and assembly machine technology, applied in the field of clamp processing, can solve the problems of cumbersome operation, high labor intensity, low efficiency, etc., and achieve the effect of increasing the suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

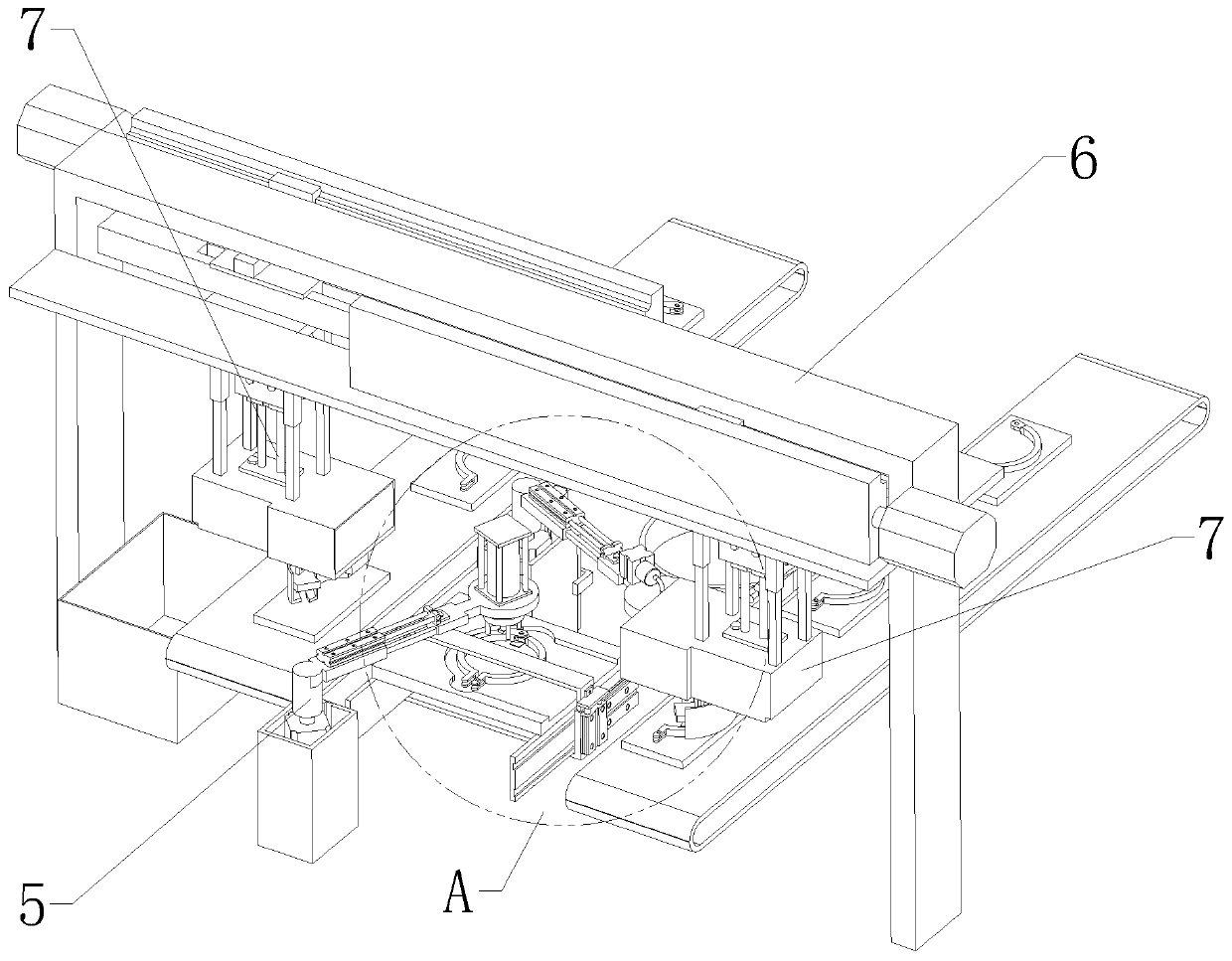

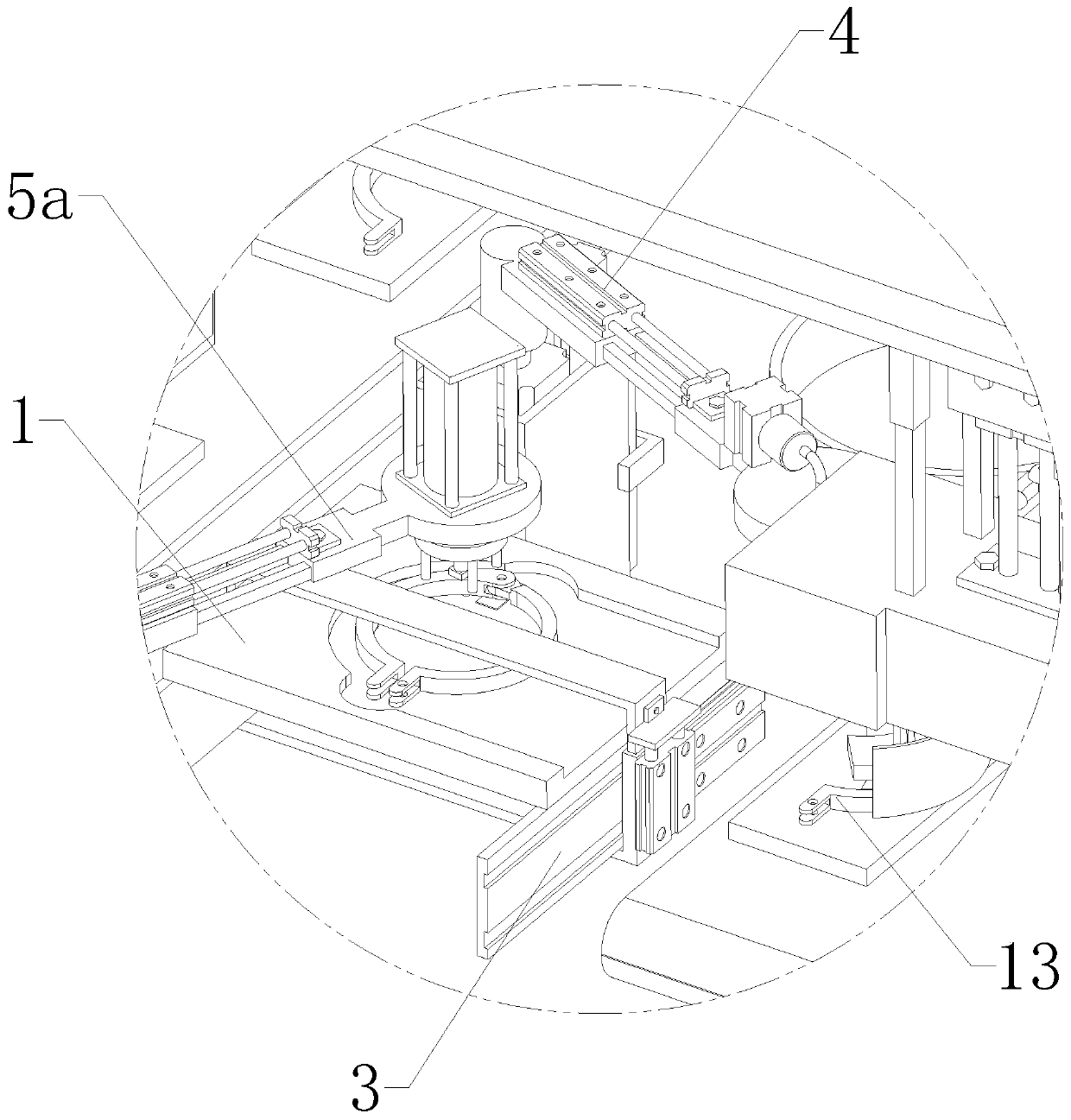

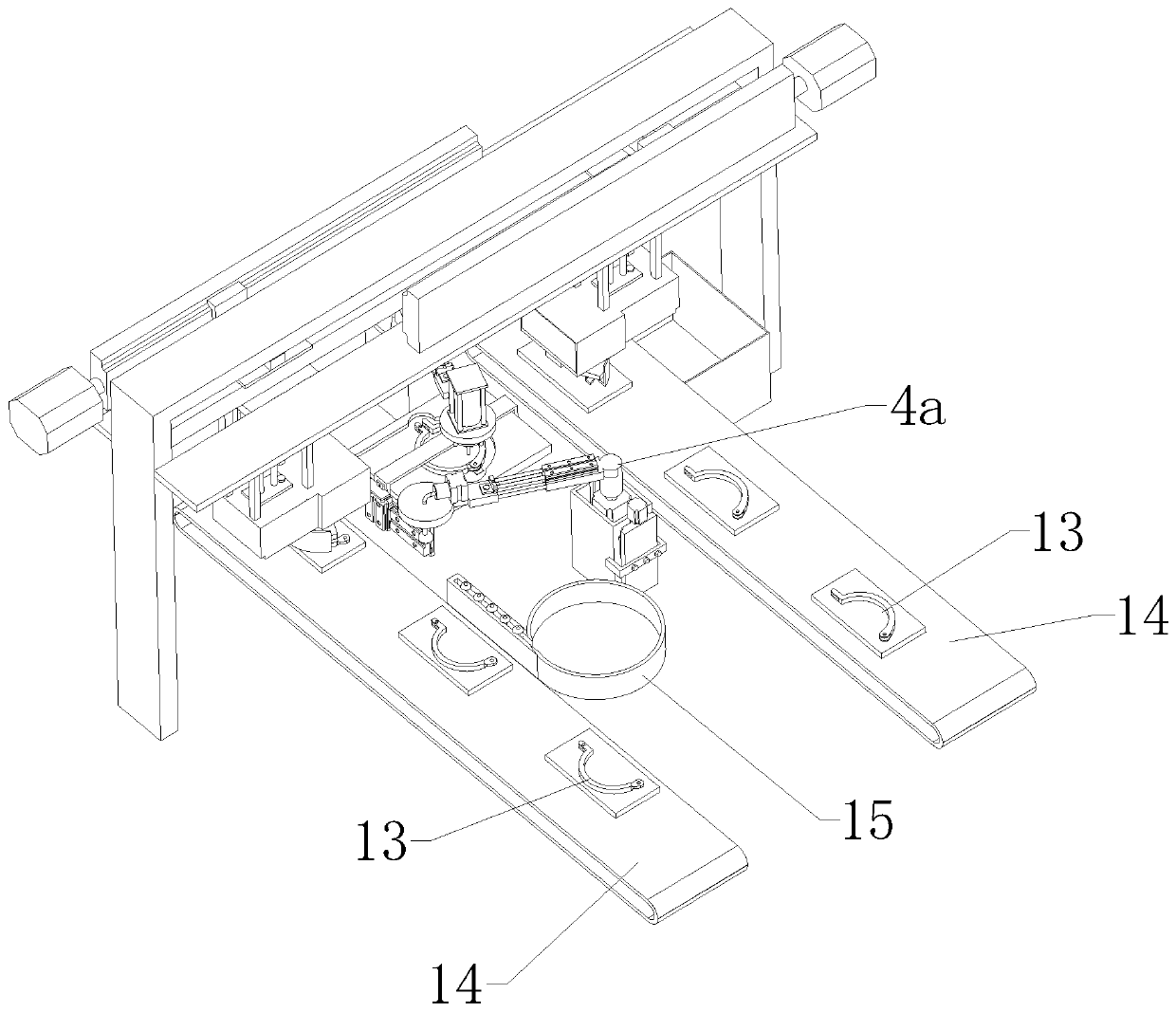

[0029] refer to Figure 1 to Figure 12The described automatic assembly machine for single rivet clamps includes two symmetrical conveyor belts 14, and also includes a butt joint device for splicing the two sub-parts 13 of the clamp 12, which is arranged between the two conveyor belts 14 And also located at the downstream end of the two support limit devices and the rivet feeding device 4 and the lower pressure riveting device 5 symmetrically arranged on both sides of the support limit device, the support limit device includes the processing plate 1 and is arranged on the processing plate 1 above and capable of horizontal movement of the limit assembly 3, the rivet feeding device 4 includes a first transfer mechanical arm 4a and a rivet absorber, the rivet absorber is rotatably arranged above the processing plate 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com