Electric soldering iron and automatic tin bar supply device thereof

An electric soldering iron and automatic technology, applied in the direction of tin feeding device, soldering iron, metal processing equipment, etc., can solve the problems of complex and bulky structure, inconvenient operation, high production cost, etc., and achieve the goal of reducing labor intensity, convenient operation and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

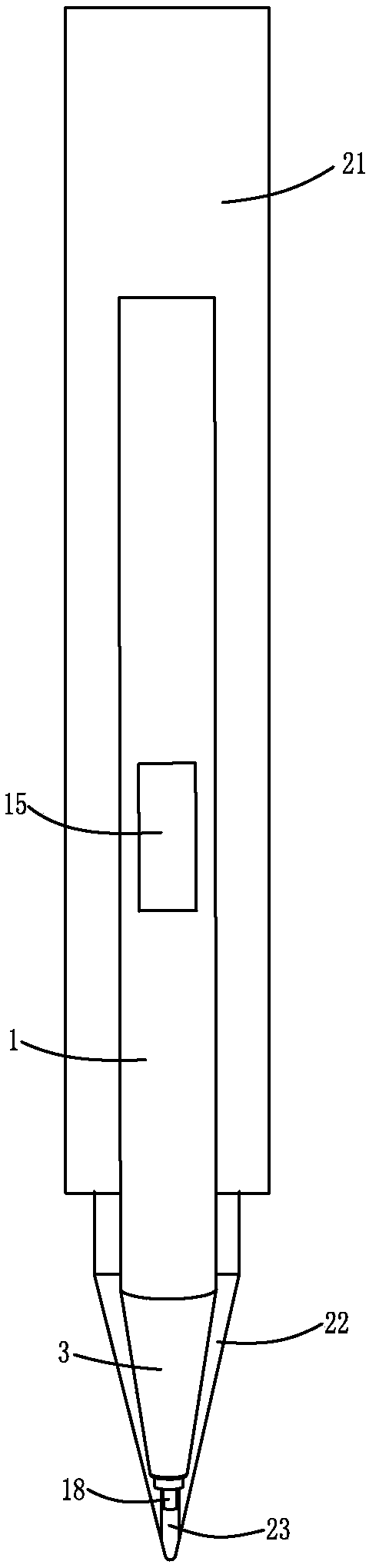

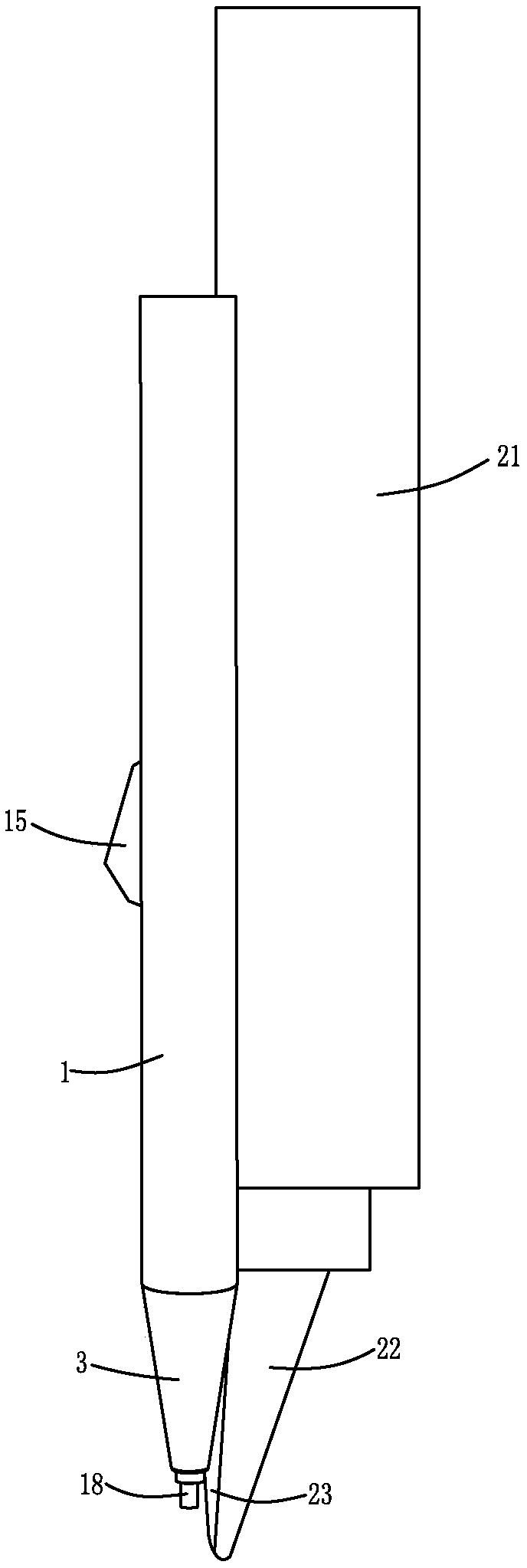

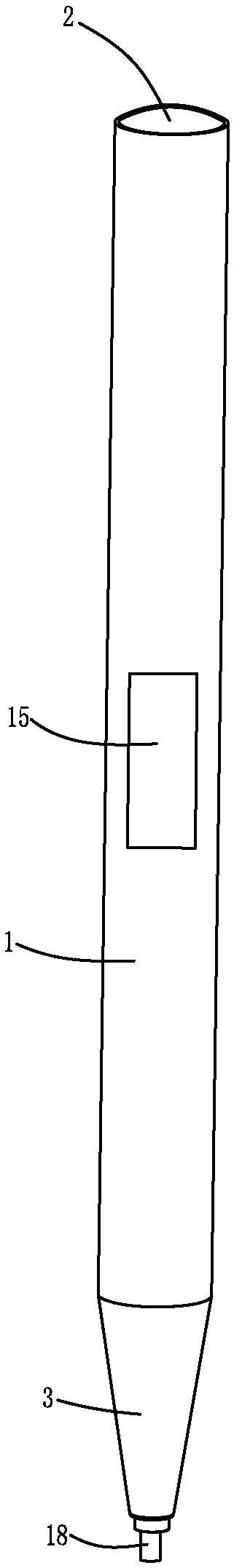

[0034] the following to Figure 1 to Figure 13 Shown, the specific embodiment of the present invention is described.

[0035] Such as image 3 , Figure 4 As shown, an automatic tin feeding device suitable for an electric soldering iron includes a cylindrical cylinder body 1, a tin bar inlet 2 is provided at the upper end of the cylinder body 1, and a detachable seal is provided at the tin bar inlet 2 at the upper end of the cylinder body 1. Blocking piece 20; a tapered sleeve 3 is provided at the lower end of the cylinder body 1, and a tin strip outlet 4 is provided at the bottom end of the tapered sleeve 3.

[0036] Such as Figure 4 , Figure 5 , Figure 6 As shown, the cylinder body 1 is provided with a material storage cylinder 5, a pressure spring 6, an opening member 7, and a locking ring 8 from top to bottom. Offer the inner cavity 9 that is used to store tin bar in the material storage tube 5, and offer the tin bar passage hole 10 and its inner cavity 9 at the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com