Shuttle vehicle capable of picking and putting cargos in intensive warehouse

A shuttle car, intensive technology, applied in the field of shuttle car, can solve the problems of high manufacturing cost, large size of the whole machine, complex structure, etc., and achieve the effects of easy maintenance, reduced overall machine volume, and reasonable structure setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be clearly and completely described below.

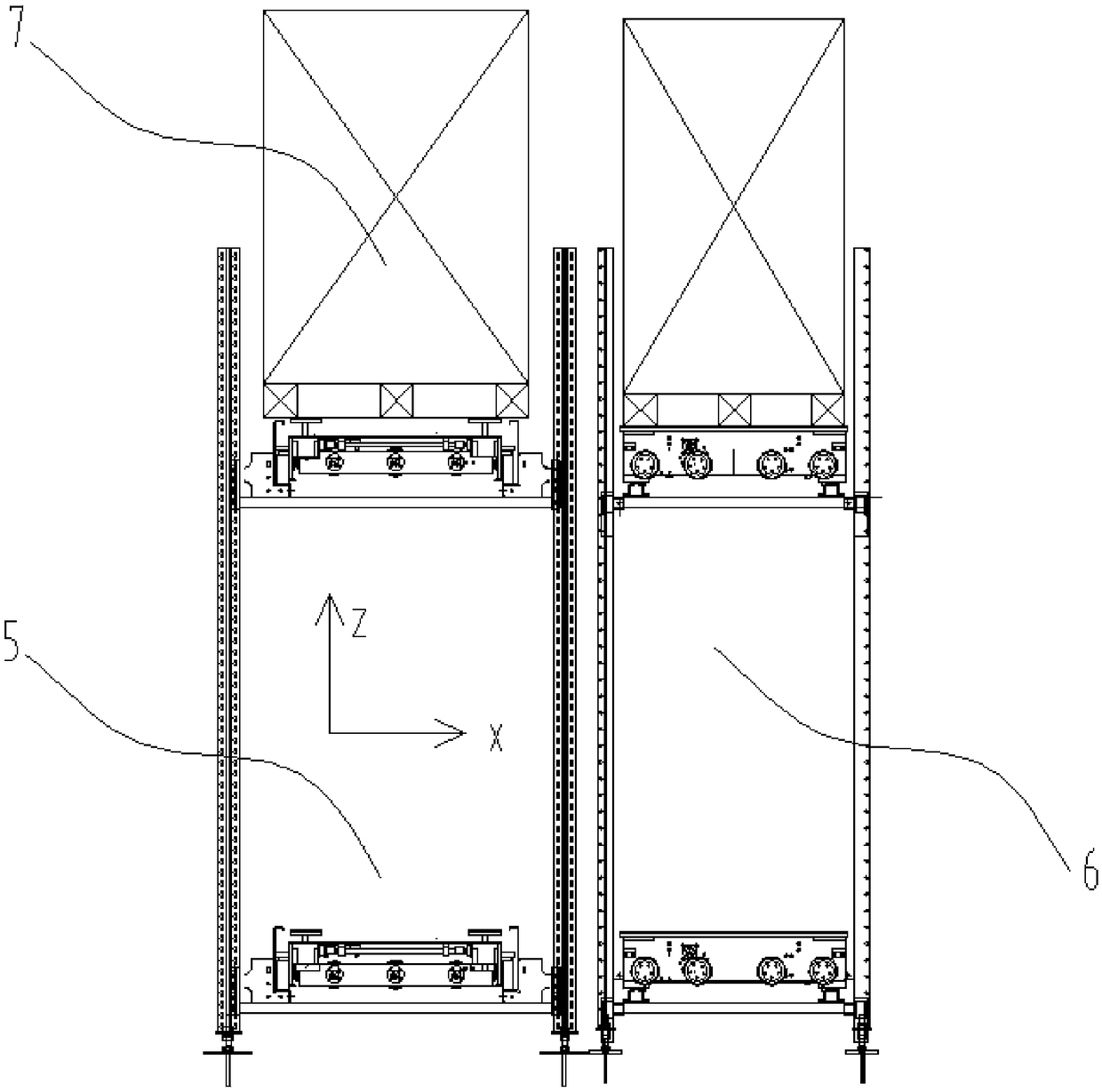

[0035] It should be noted that, in order to illustrate the connection relationship of various structures in the present invention, the "horizontal" in the present invention refers to figure 1 In the Y direction of the middle coordinate, the "straight line" or "longitudinal" described in the present invention refers to figure 1 The X direction of the middle coordinate, as well as the orientation terms such as "horizontal" and "vertical" described in the present invention, all refer to figure 1 In terms of orientation, it should not be construed as a limitation of the present invention.

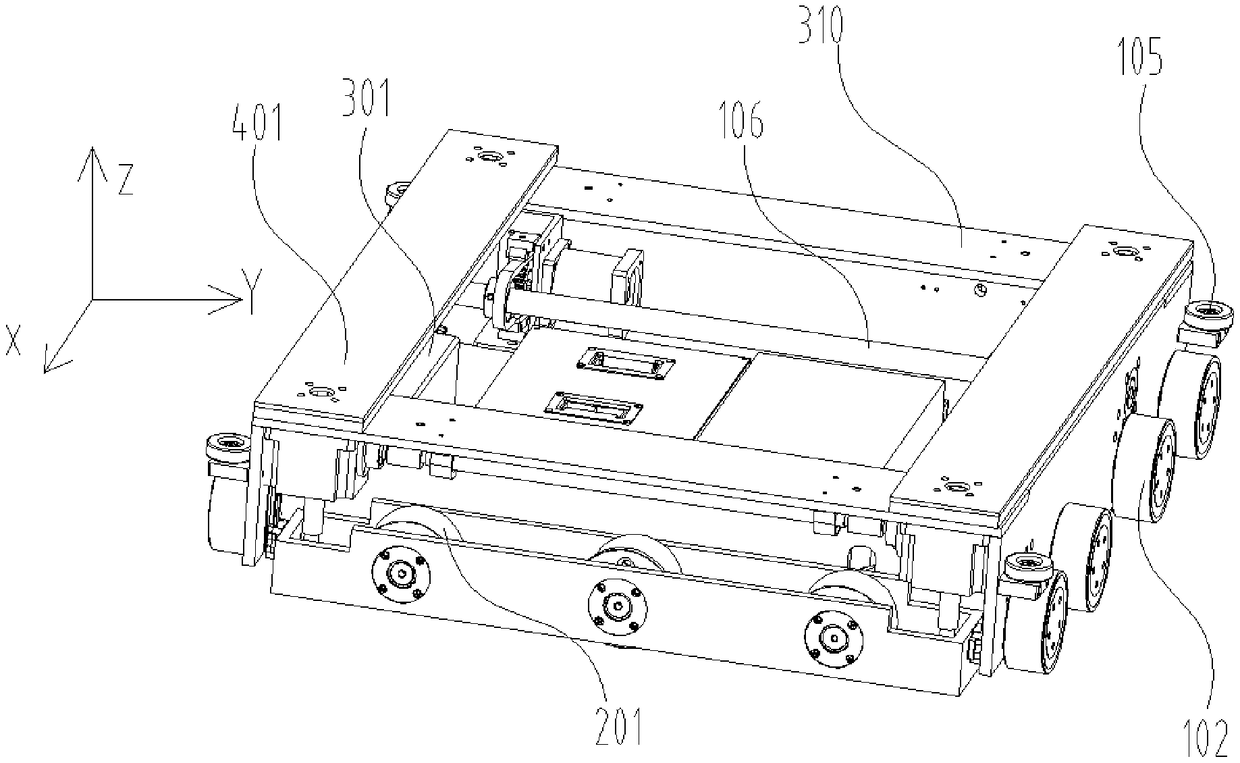

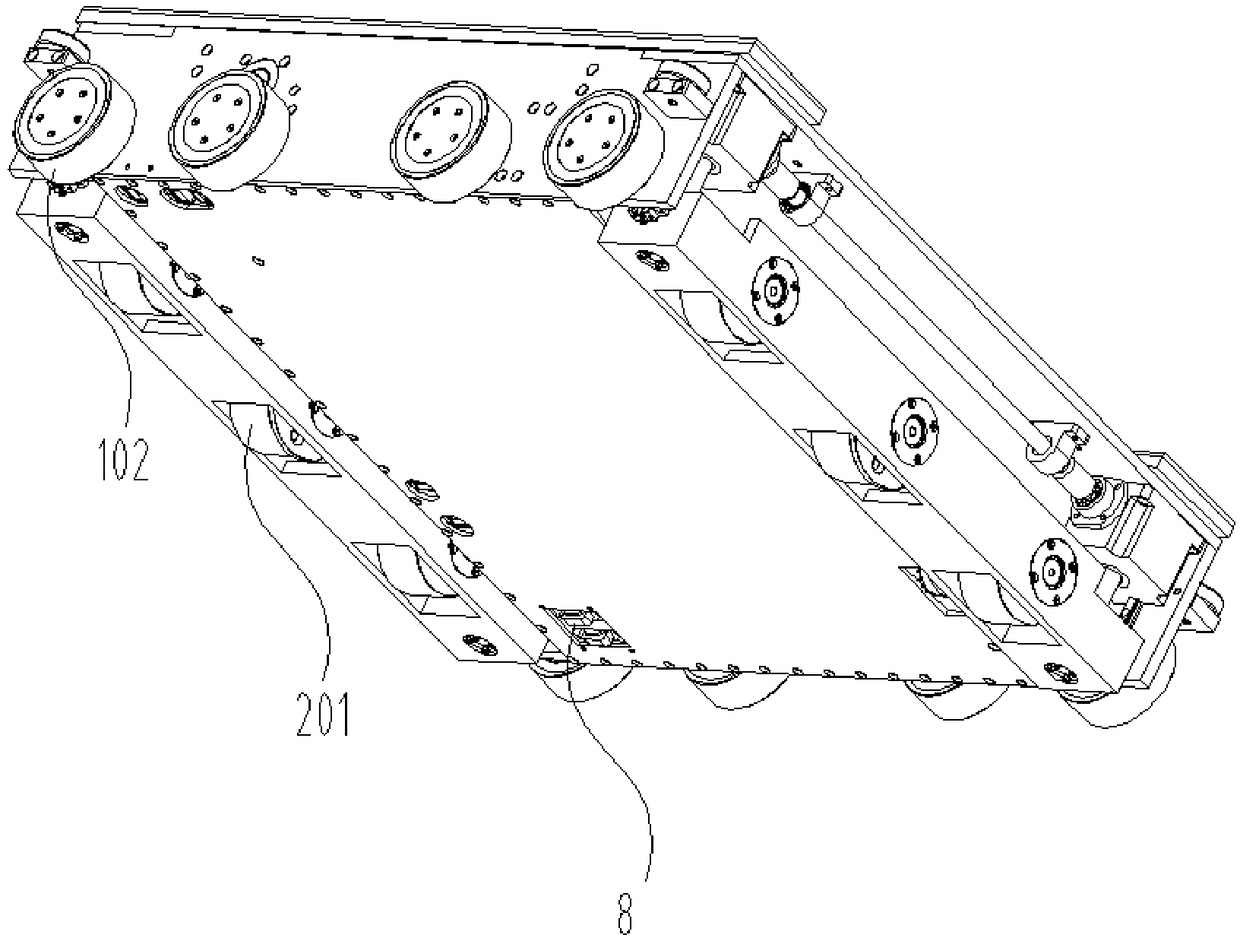

[0036] Such as figure 2 As shown, a reversing jacking integrated shuttle car for picking and placing goods in a dense warehouse, including:

[0037] Straight travel mechanism, used to realize the straight travel movement of the shuttle car;

[0038] The lateral movement mechanism is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com