Fault identification method, device and system for conveyor

A fault identification and conveyor technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of sound signal noise interference and inaccurate fault detection of idlers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

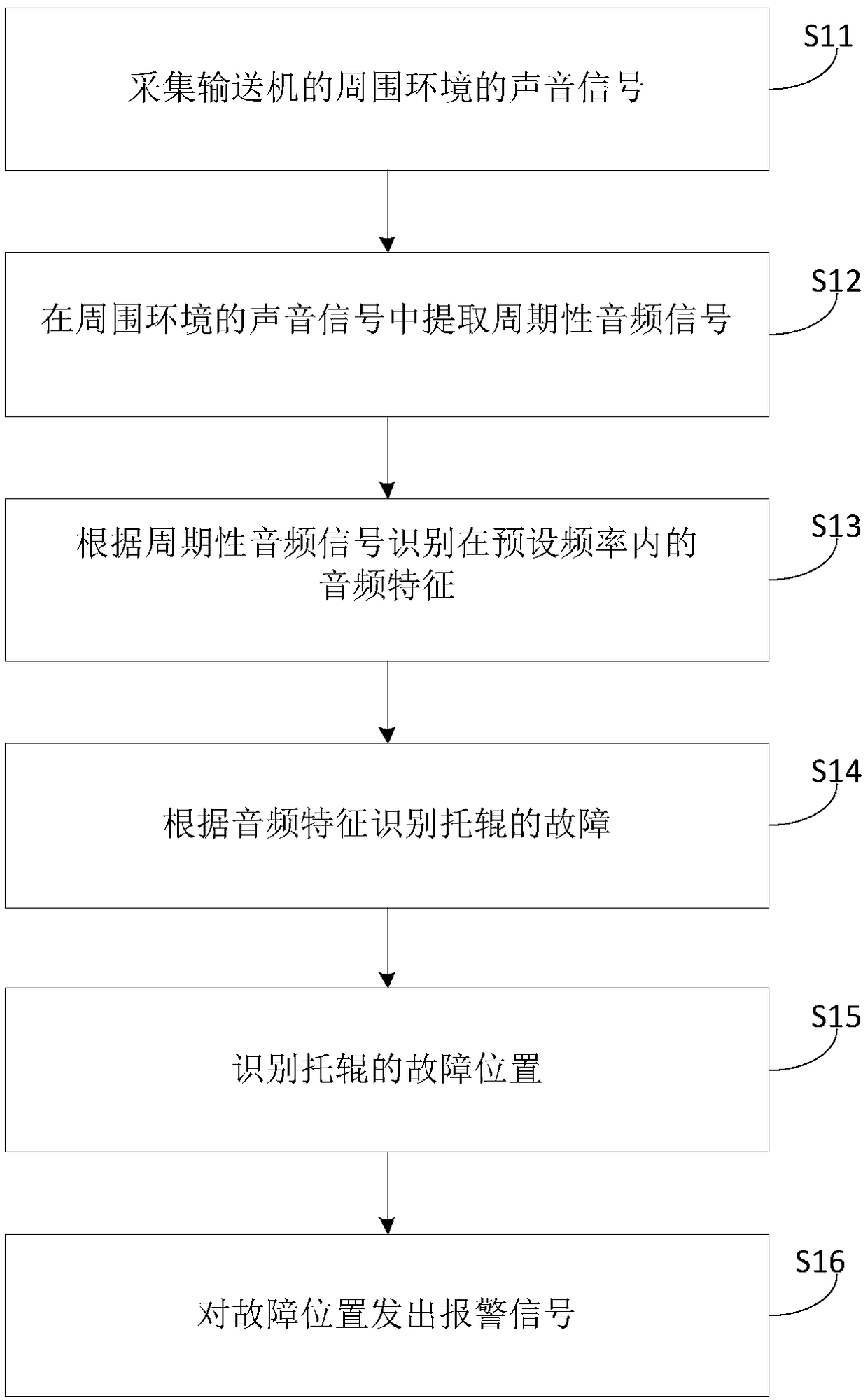

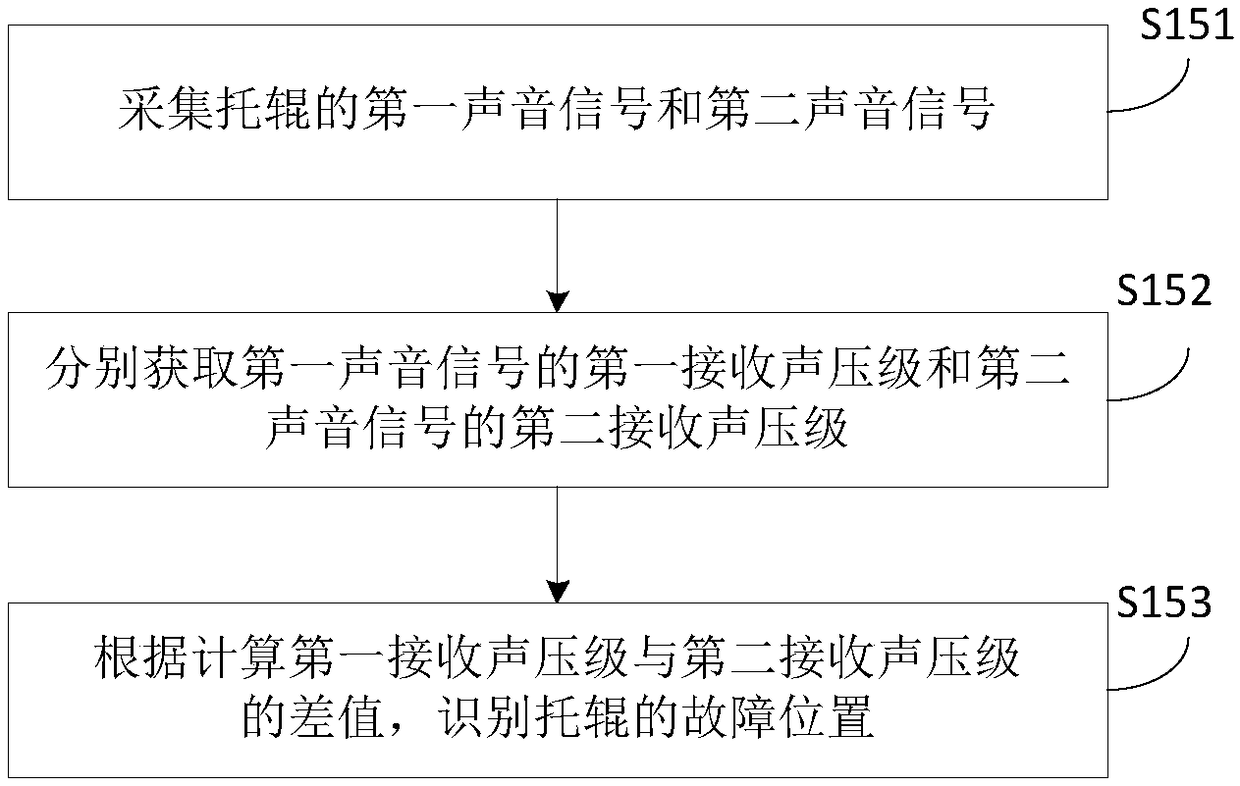

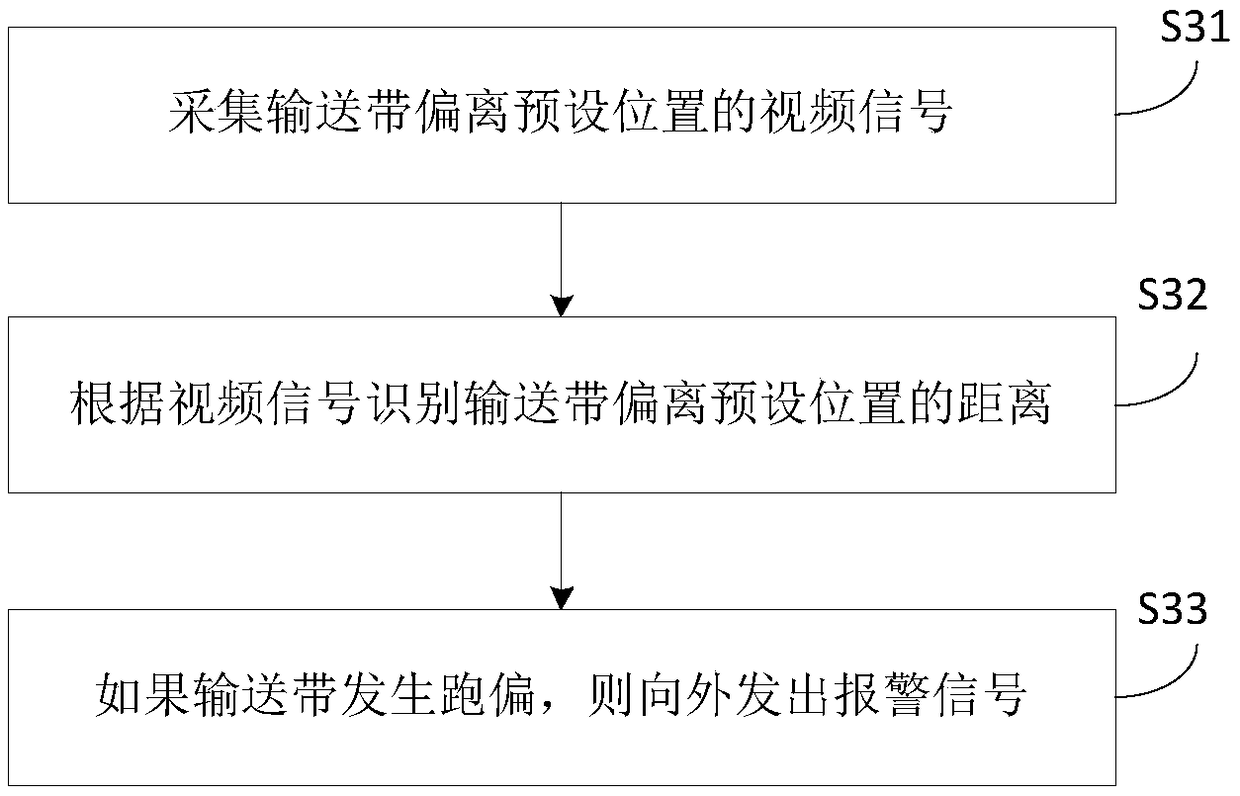

[0060] An embodiment of the present invention provides a fault identification method for a conveyor. The conveyor includes a conveyor belt and idler rollers supporting the conveyor belt. The conveyor belt moves through the idler rollers, so that different materials can be transported. Such as figure 1 shown, including the following steps:

[0061] S11. Acquiring sound signals of the surrounding environment of the conveyor. The sound signals of the surrounding environment here are all sound signals within the acceptance range of the sound sensor, including the sound signals of the normal operation of the conveyor, other sound signals from the surrounding environment, and periodic high-frequency sound signals emitted by the faulty idler roller when it rotates , so the sound signal of the surrounding environment is a mixed sound signal.

[0062] S12. Extract the periodic audio signal from the sound signal of the surrounding environment. The periodic sound signal here refers to...

Embodiment 2

[0082] An embodiment of the present invention provides a conveyor fault identification device, such as Figure 5 shown, including:

[0083] The first collection module 51 is used to collect the sound signal of the surrounding environment of the conveyor;

[0084] The extraction module 52 is configured to extract the periodic audio signal from the sound signal of the surrounding environment.

[0085] The first identifying module 53 is configured to identify audio features within a preset frequency according to the periodic audio signal.

[0086] The second identification module 54 is configured to identify the failure of the idler according to the audio signal.

[0087] The fault identification device of the conveyor provided by the embodiment of the present invention also includes:

[0088] The third identification module 55 is used to identify the fault position of the idler roller.

[0089] The first alarm module 56 is configured to send an alarm signal to the fault loca...

Embodiment 3

[0105] An embodiment of the present invention provides a conveyor fault identification system, which is used in the conveyor fault identification method in Embodiment 1, such as Figure 7 shown, including:

[0106] The first sound sensor 71 is used to collect the sound signal of the idler roller. The first sound sensor 71 is used to detect the sound signal of 20kHz-200kHz, and the first sound sensor 71 can identify the fault of the idler roller of the conveyor by detecting the frequency signal.

[0107] Such as Figure 8 As shown, the controller 73 includes a memory 820, a processor 810, and a computer program stored on the memory 820 and operable on the processor 810. When the processor 810 executes the program, it is used to collect the sound of the conveyor according to the first sound sensor 71. The sound signal of the surrounding environment; the periodic audio signal is extracted from the sound signal of the surrounding environment; the audio feature within the preset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com