Superspeed elevator car

An elevator car, ultra-high-speed technology, applied in elevators in buildings, non-rotational vibration suppression, transportation and packaging, etc., can solve problems such as inability to prevent mutual influence and transmission, no better technical solutions, and inability to isolate the shaft , to achieve the effect of reducing noise and vibration, easy to implement, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, and specific implementation methods will be given.

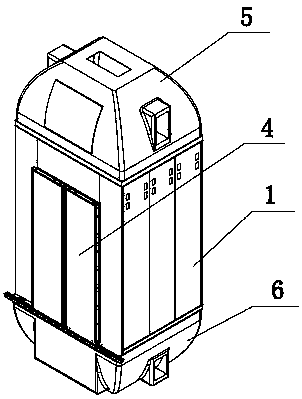

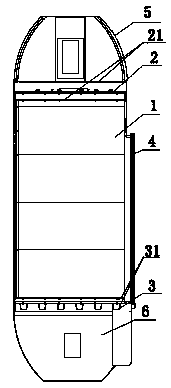

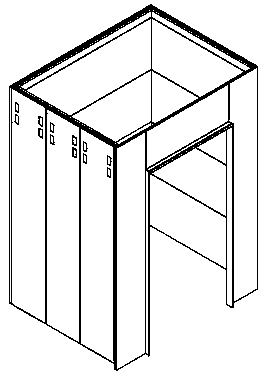

[0024] like Figure 1-6 As shown, the present invention is an ultra-high-speed elevator car, its main purpose is to provide a complete technical solution for reducing the noise and vibration of the elevator car, and the design of each component can be combined and used according to the actual running speed of the elevator for Super high-speed elevator with a speed of 6-18m / s.

[0025] The specific structure includes a sound-proof and shock-absorbing car wall 1, a sound-insulating and shock-absorbing car roof 2, a sound-insulating and shock-absorbing car floor 3, a car door 4, an upper nozzle 5 and a lower nozzle 6; a sound-proof and shock-absorbing car wall 1, which includes a car The car wall base plate 11 of the car, and the adjacent car wall base plates 11 are connected and arranged through a shock absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com