Device for burning and heating gas

A technology for heating gas and boxes, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of rising oil and natural gas prices, lower thermal efficiency, small heat exchange area, etc., and achieve easy promotion and application , fast heat raising speed and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

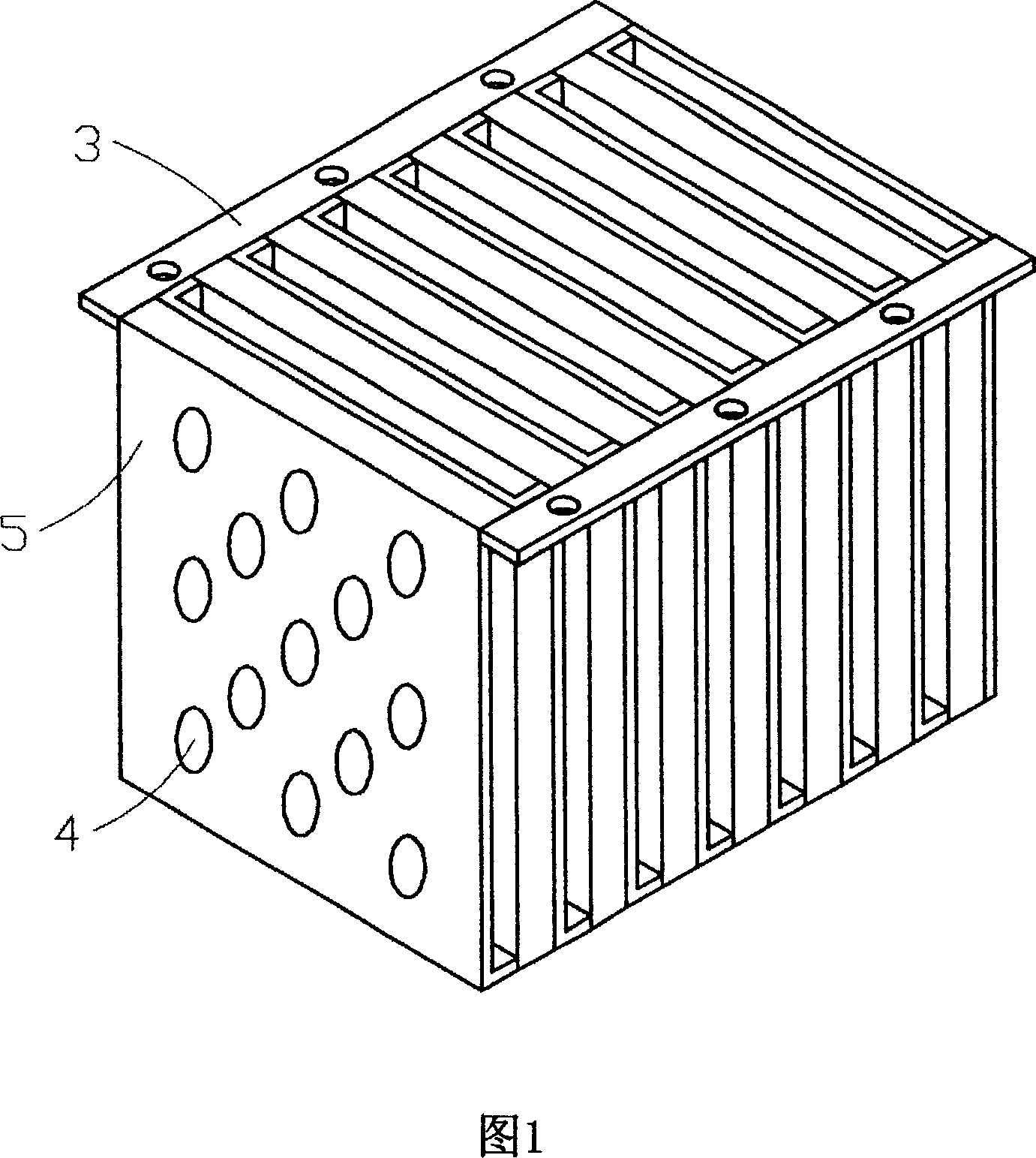

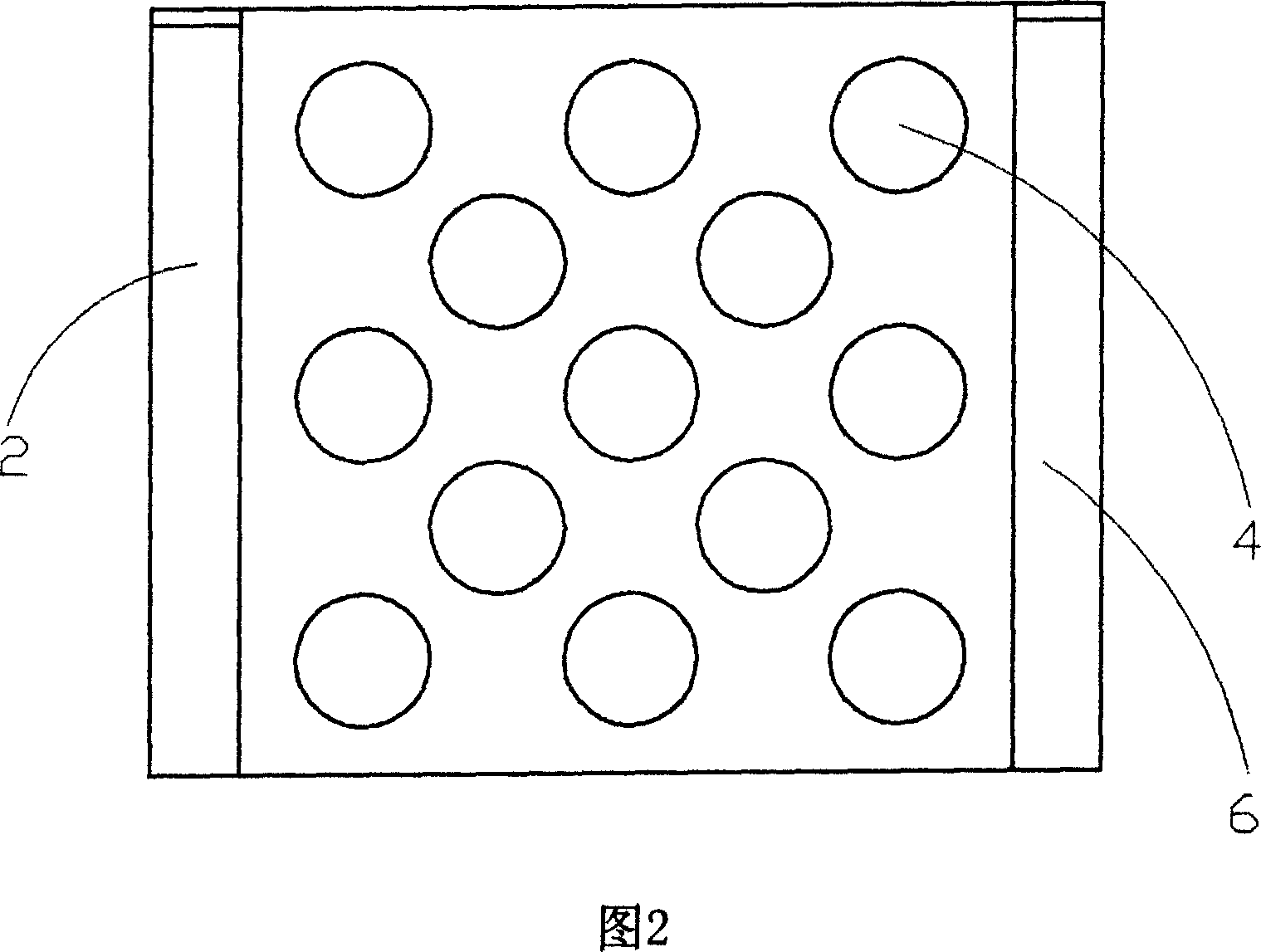

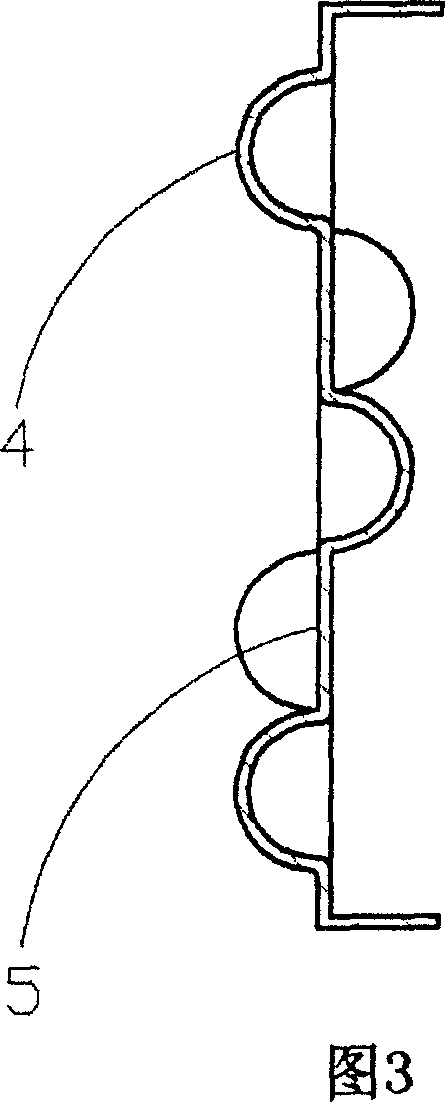

[0018] As shown in the figure, the combustion heating gas device involved in the present invention includes a box body 1, a connecting bar 3, an air inlet valve 2 and an air outlet connecting plate 6. The box body 1 is composed of many The concavo-convex body 4 is composed of several "匚" shaped metal sheet frames 5, and the two bent ends of the "匚" shaped metal sheet frame 5 are fixedly connected with the next "匚" shaped metal sheet frame 5 respectively, One of the opening directions of the two adjacent "匚" shaped metal sheet frames 5 is set horizontally, and the other is set vertically, with a difference of 90 degrees between them.

[0019] The air inlet valve 2 and the air outlet connecting plate 6 are respectively fixed on lateral sides of the box body 1 .

[0020] The connecting strips 3 are fixed on the upper edges of both sides of the box body 1 .

[0021] The shape of the concave-convex body 4 provided on the "匚"-shaped thin metal plate frame 5 can be semicircle, ellip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com