Magnetostriction-piezoelectric composite material and preparation method thereof

A piezoelectric composite material, a technology of magnetostrictive materials, applied in the selection of materials for magnetostrictive devices, the selection of materials for piezoelectric devices or electrostrictive devices, the manufacture of piezoelectric/electrostrictive devices/ Assembly and other directions can solve the problems of limiting the catalytic degradation rate of piezoelectric materials, and achieve the effects of cost saving, ensuring insulation performance and large interface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

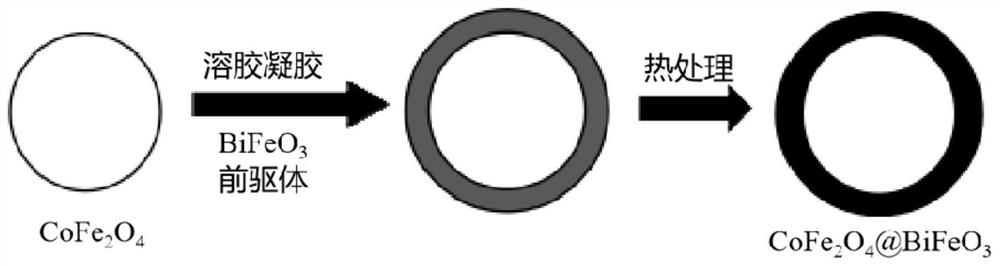

[0038] This embodiment prepares a magnetostrictive-piezoelectric composite material with a core-shell structure, and the magnetostrictive material CoFe 2 o 4 Nanoparticles are the core material of the core-shell structure, and the piezoelectric material Pb(Zr,Ti)O 3 As the shell layer, the magnetostrictive material was synthesized by the hydrothermal method, the piezoelectric material precursor was synthesized by the sol method, and then the piezoelectric material shell was wrapped around the magnetostrictive material by the sol-gel method. The schematic diagram of its preparation Such as figure 2 As shown, the specific preparation steps are as follows:

[0039] (1)Pb(Zr 0.52 Ti 0.48 )O 3 Preparation: lead acetate trihydrate (Pb(CH 3 COO) 2 ·3H 2 O), zirconium n-propoxide (Zr[CH 3 (CH 2 ) 2 O] 4 ), isopropanol titanate (Ti[CH 3 (CH 2 ) 2 O] 4 ) as a raw material, three raw materials are dissolved in glacial acetic acid (CH 3 COOH) solvent, then add 5% (relati...

Embodiment 2

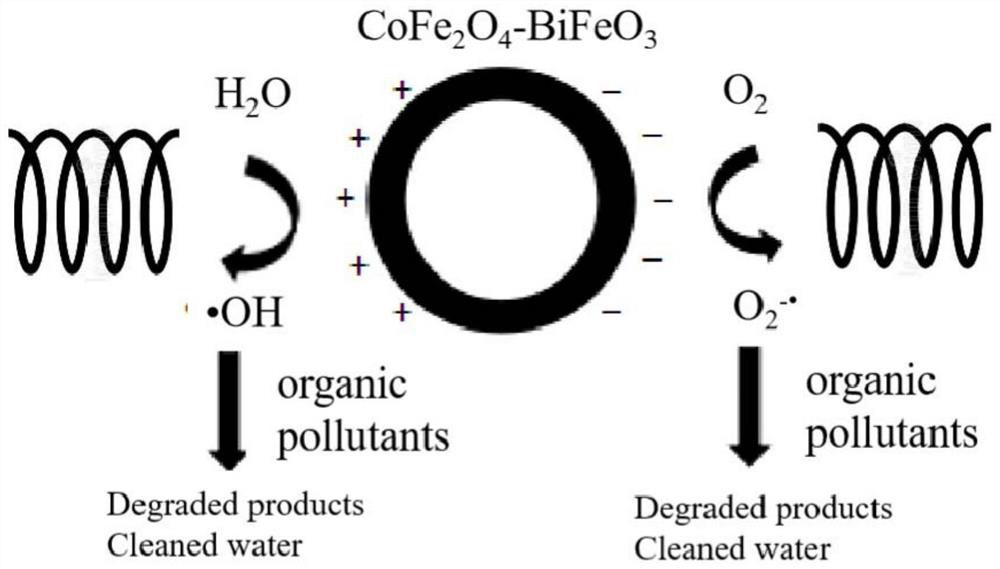

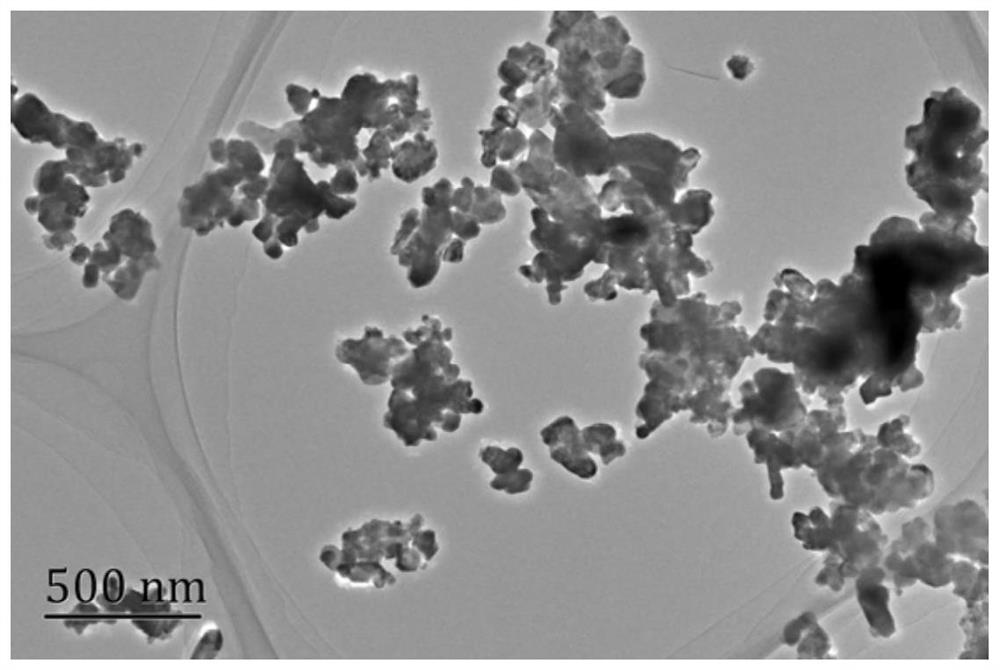

[0044] This embodiment prepares a magnetostrictive-piezoelectric composite material with a core-shell structure, and the magnetostrictive material CoFe 2 o 4 Nanoparticles are the core material of the core-shell structure, and the piezoelectric material BiFeO 3 is the shell layer, and its preparation schematic diagram is as follows figure 2 As shown, the specific preparation steps are as follows:

[0045] (1) BiFeO 3 Preparation: Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and iron nitrate (Fe(NO 3 ) 3 9H 2 O) is raw material, is dissolved in the acetic acid solution of 1:1 according to molar ratio, and excessively adds bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) 1%, in order to prevent the hydrolysis of bismuth, heat several times at 70 ℃, until the solute basically dissolves. Add acetic acid and ethylene glycol according to the ratio of acetic acid:ethylene glycol of 1:1, heat and stir at 100°C to form a rust-red transparent sol, namely BiFeO 3 Precursor.

[0046] It was ...

Embodiment 3

[0051] This embodiment prepares a magnetostrictive-piezoelectric composite material with a core-shell structure, and the magnetostrictive material CoFe 2 o 4 Nanoparticles are the core material of the core-shell structure, and the piezoelectric material BiFeO 3 is the shell layer, and its preparation schematic diagram is as follows figure 2 As shown, the specific preparation steps are as follows:

[0052] (1) BiFeO 3 Preparation: Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and iron nitrate (Fe(NO 3 ) 3 9H 2 O) is raw material, is dissolved in the acetic acid solution of 1:1 according to molar ratio, and excessively adds bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) 1%, in order to prevent the hydrolysis of bismuth, heat several times at 70 ℃, until the solute basically dissolves. Add acetic acid and ethylene glycol according to the ratio of acetic acid: ethylene glycol = 1:1, heat and stir at 100°C to form a rust-red transparent sol, namely BiFeO 3 Precursor.

[0053] It was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com