Sewing machine without bobbins

A sewing machine and bobbin technology, applied in the direction of sewing machine components, sewing machine ring mechanism, sewing equipment, etc., can solve the problems of reducing the sewing efficiency of the sewing machine, inconvenient use of the sewing machine, etc., so as to improve the sewing efficiency, reduce the possibility, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

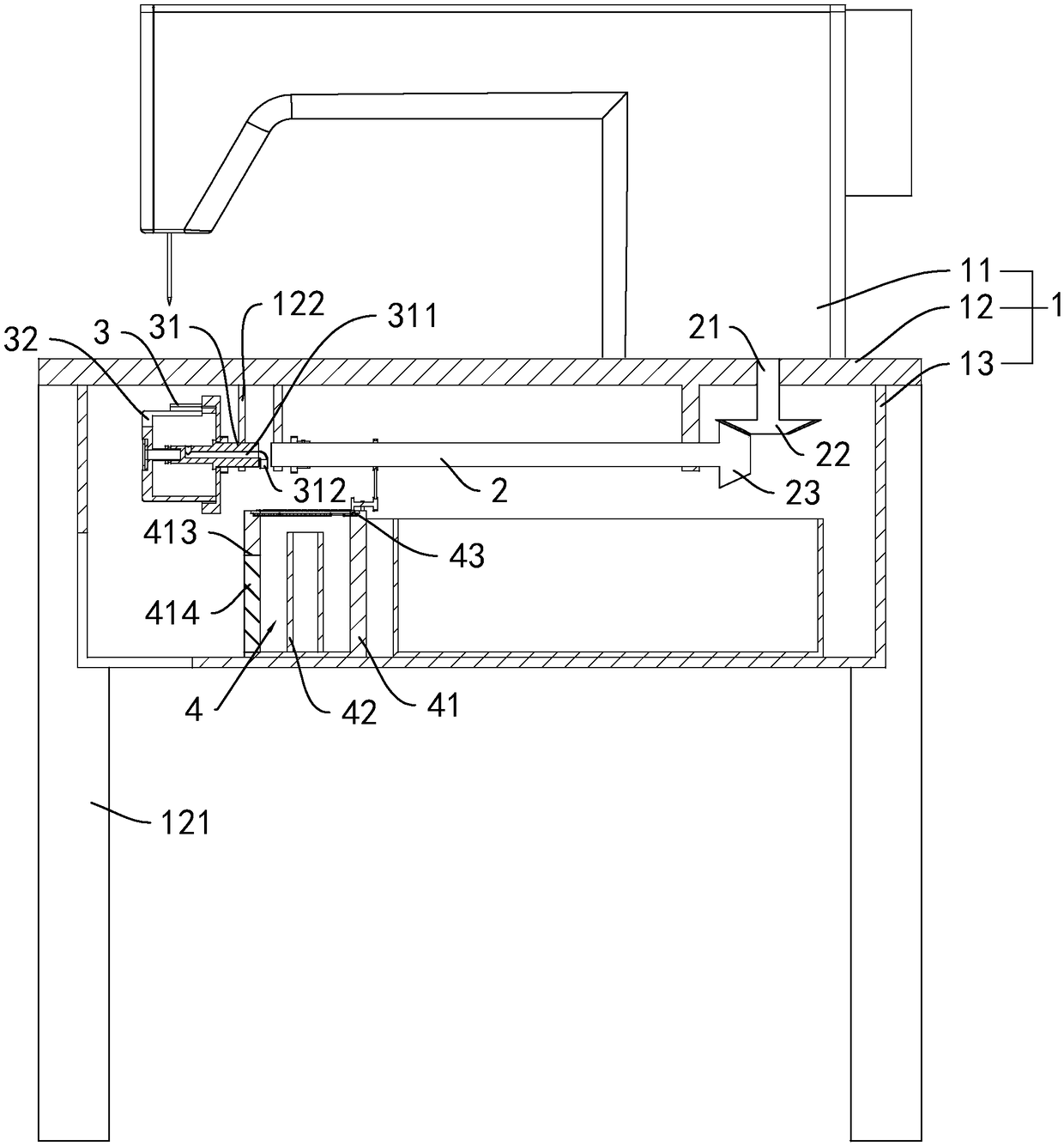

[0043] Embodiment 1: a kind of bobbinless sewing machine, as figure 1As shown, it includes a frame 1, a feeding structure, a wire jumper structure, a thorn material structure and a hook wire structure. The frame 1 includes a platen 12, an upper case 11 and a lower case 13, the upper case 11 and the lower case 13 are respectively fixedly connected to the upper and lower ends of the platen 12, and the platen 12 is fixedly connected with a fixed frame 121 for supporting. The jumper structure and the spur structure are installed on the upper case 11 . Feeding structure and hook line structure are installed in lower cabinet 13. A driving motor is installed in the upper chassis 11, and the driving motor is used to provide power for the feeding structure, jumper structure, stab material structure and hook line structure.

[0044] Such as figure 1 As shown, the thread hook structure includes a lower shaft 2 , a rotary hook 3 , a guide rod 31 and a thread supply assembly 4 . The lo...

Embodiment 2

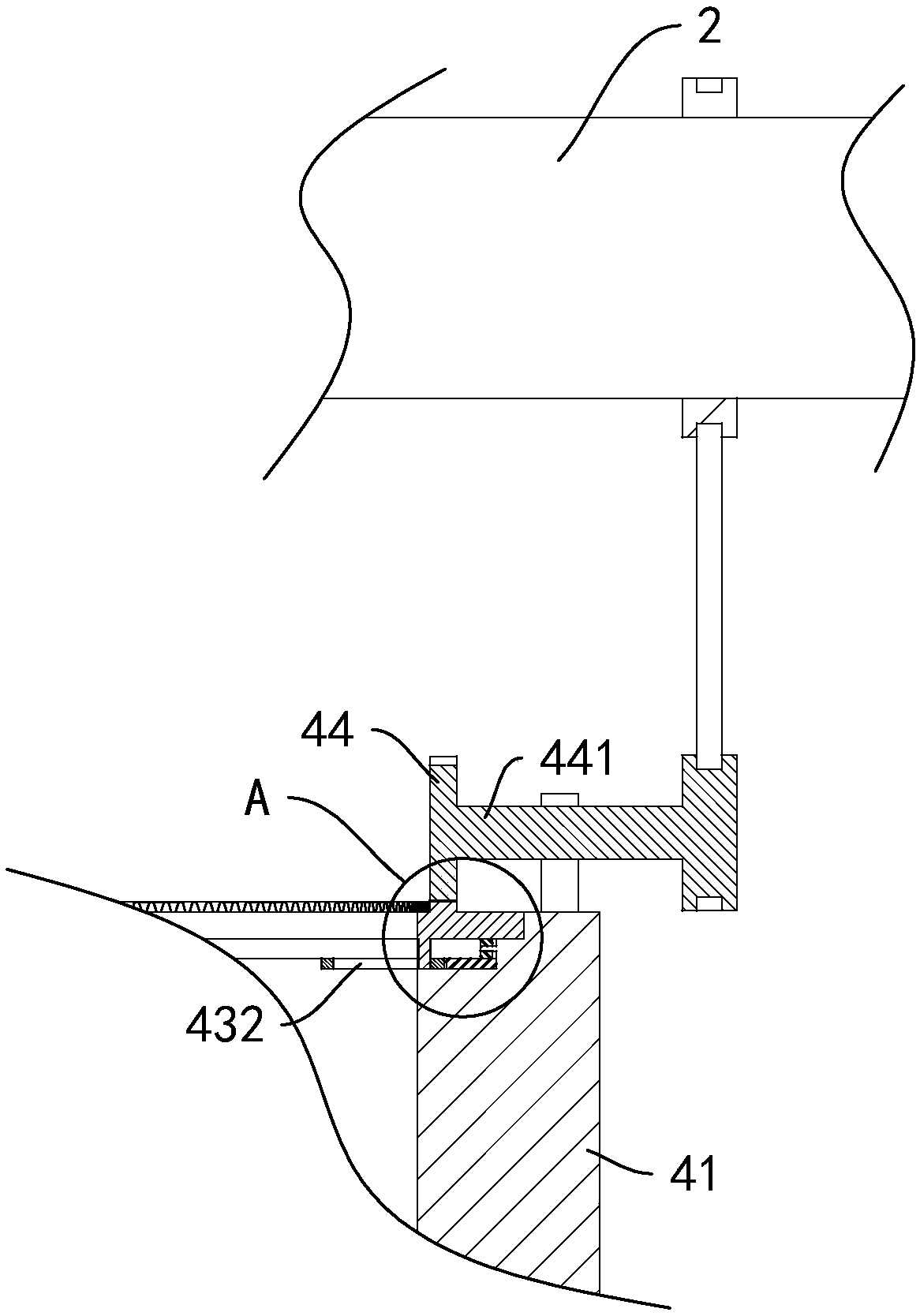

[0051] Embodiment 2, a kind of bobbinless sewing machine, such as Figure 5 As shown, the difference from Embodiment 1 is that the wire supply assembly 4 is located below the lower case 13 , and the lower case 13 is provided with a plurality of wire loops 132 . The right end of the lower case 13 is provided with a wire through hole 131 , and the wire supply assembly 4 is located vertically below the wire through hole 131 . The wire supply assembly 4 includes an installation cylinder 41, a cylinder 42 and an untwisting structure 43. The installation cylinder 41 is cylindrical in shape with an upper end open, and the bobbin 42 is wound with a bottom thread. The bobbin 42 is placed in the installation cylinder 41, and the installation cylinder 41 is used to prevent miscellaneous Objects come into contact with the bottom thread and affect sewing. The bobbin thread on the bobbin 42 is unrolled and passed through the untwisting structure 43 and then enters the lower casing 13 throu...

Embodiment 3

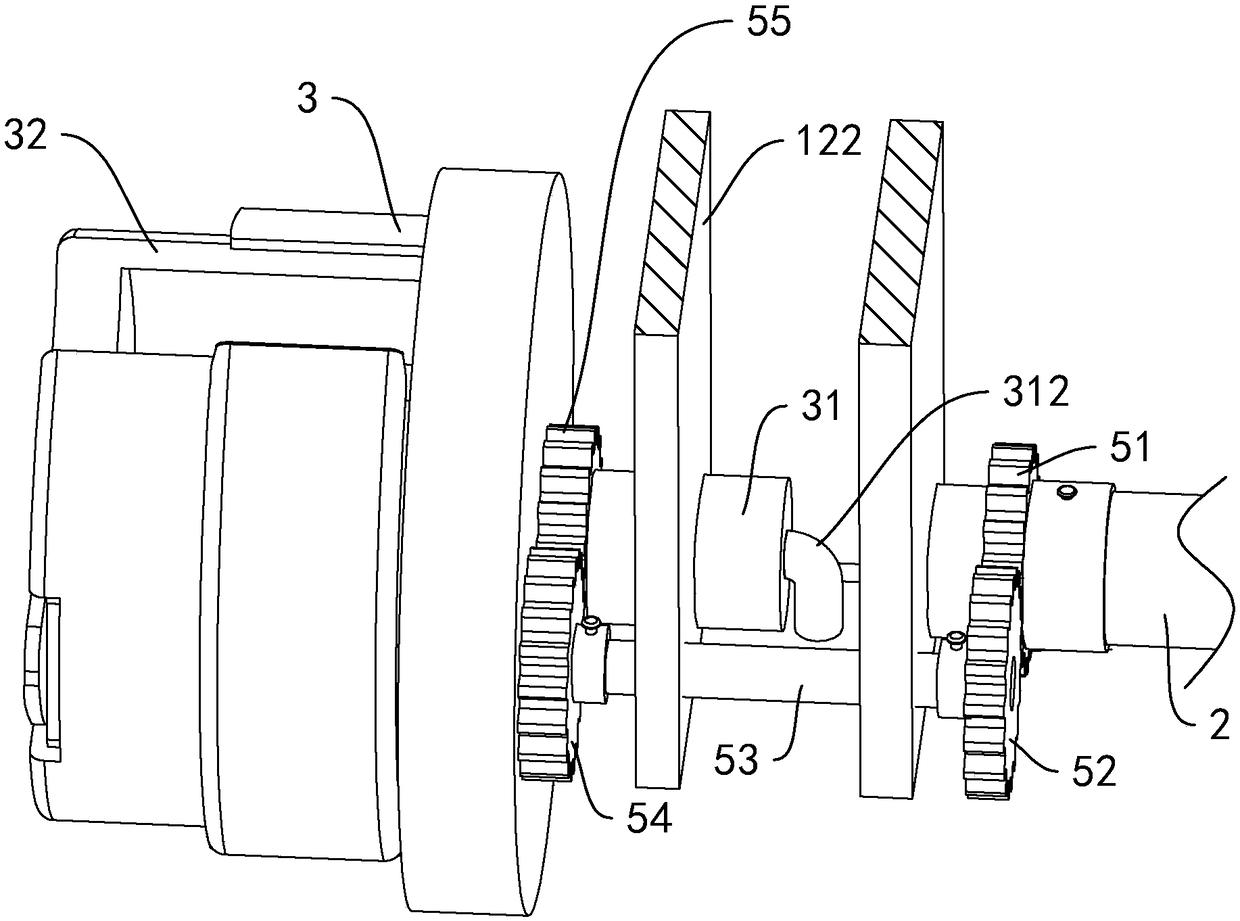

[0053] Embodiment 3, a kind of bobbinless sewing machine, such as Figure 7 As shown, the difference from Embodiment 1 is that the transmission structure 5 includes a first permanent magnet 56 and a second permanent magnet 57, both of which are bar magnets. The first permanent magnet 56 is fixedly connected with the left end of the lower shaft 2 , and the second magnet is sleeved on the guide rod 31 and fixedly connected with the rotary hook 3 . The ends of the first permanent magnet 56 and the second permanent magnet 57 are close to each other and have opposite magnetic poles. When the lower shaft 2 rotates, the first permanent magnet 56 will drive the second permanent magnet 57 to rotate. In order to avoid magnetization of the fixing base 122 , the fixing base 122 is made of aluminum and is fixedly connected to the platform 12 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com