Valve cylinder integrated element, piston cylinder actuating module and modular fluid driving device

A technology of integrated components and valve cylinders, applied in the direction of fluid pressure actuators, servo motor components, servo motors, etc., can solve the problems of increased manufacturing costs, poor flexibility, waste, etc., to improve technical and economic indicators, increase production batches, The effect of eliminating redundant functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

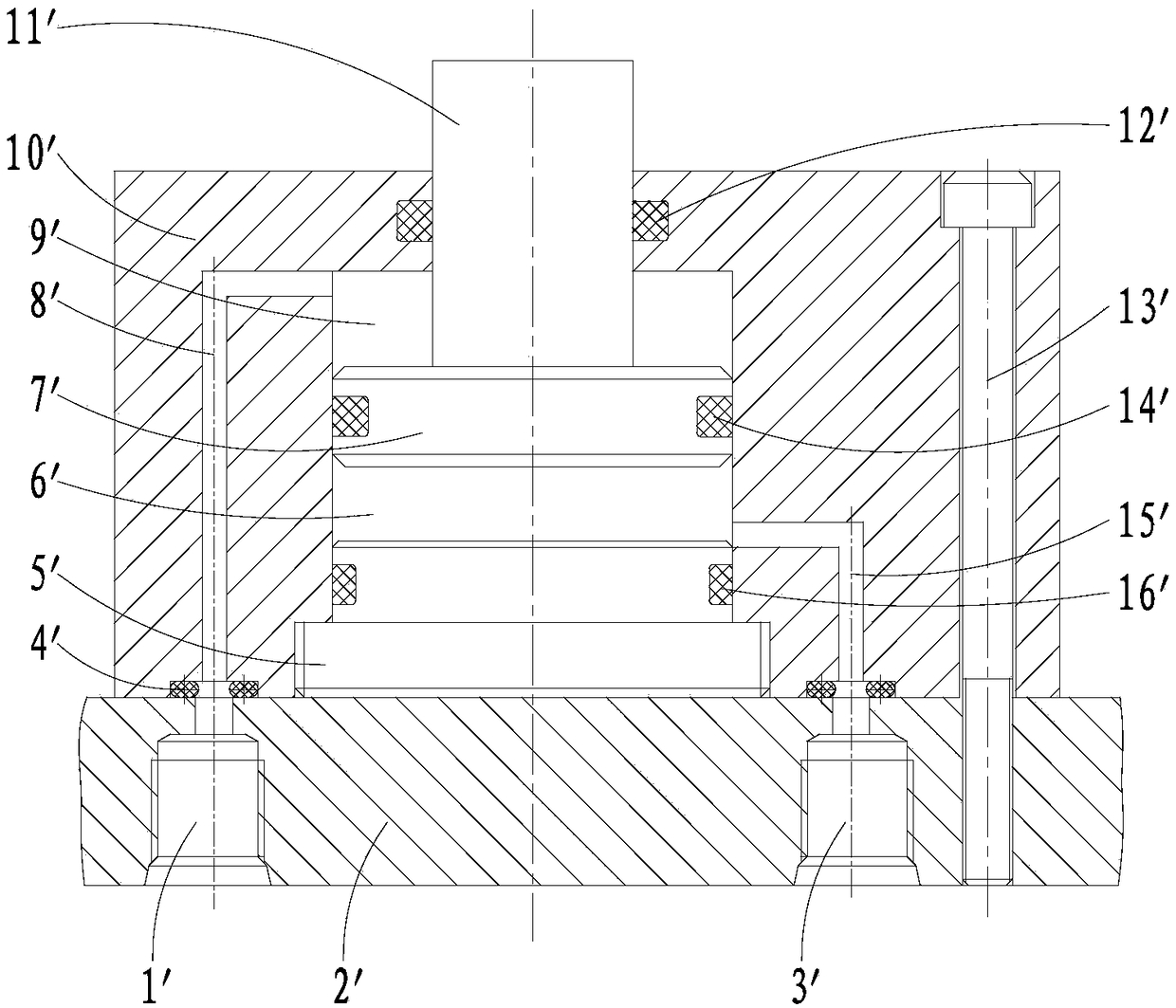

[0052] see image 3 A valve-cylinder integrated component is shown, which includes a fixed part and an actuating part. The fixed part includes a valve cylinder body 1 and a cylinder end cover 3. The actuating part includes a valve actuating element 2 and a cylinder actuating element 4. The valve cylinder The body 1 includes a valve body 11 and a cylinder body 12 . In this embodiment, the valve body 11 and the cylinder body 12 are integrated to form an integral valve cylinder body 1 .

[0053] The valve body 11 part of the valve cylinder body 1 has a valve cavity, and the valve actuator 2 is set in the valve cavity so as to reciprocate to form a reversing valve. Here, the valve actuator 2 is set in the valve cavity for linear reciprocating motion. In the spool 2, the valve body 11 has a flow control A port 111, a P port 112 and a T port 113, forming a two-position three-way reversing valve.

[0054] The cylinder body 12 of the valve cylinder body 1 has a piston hole, the cylin...

Embodiment 2

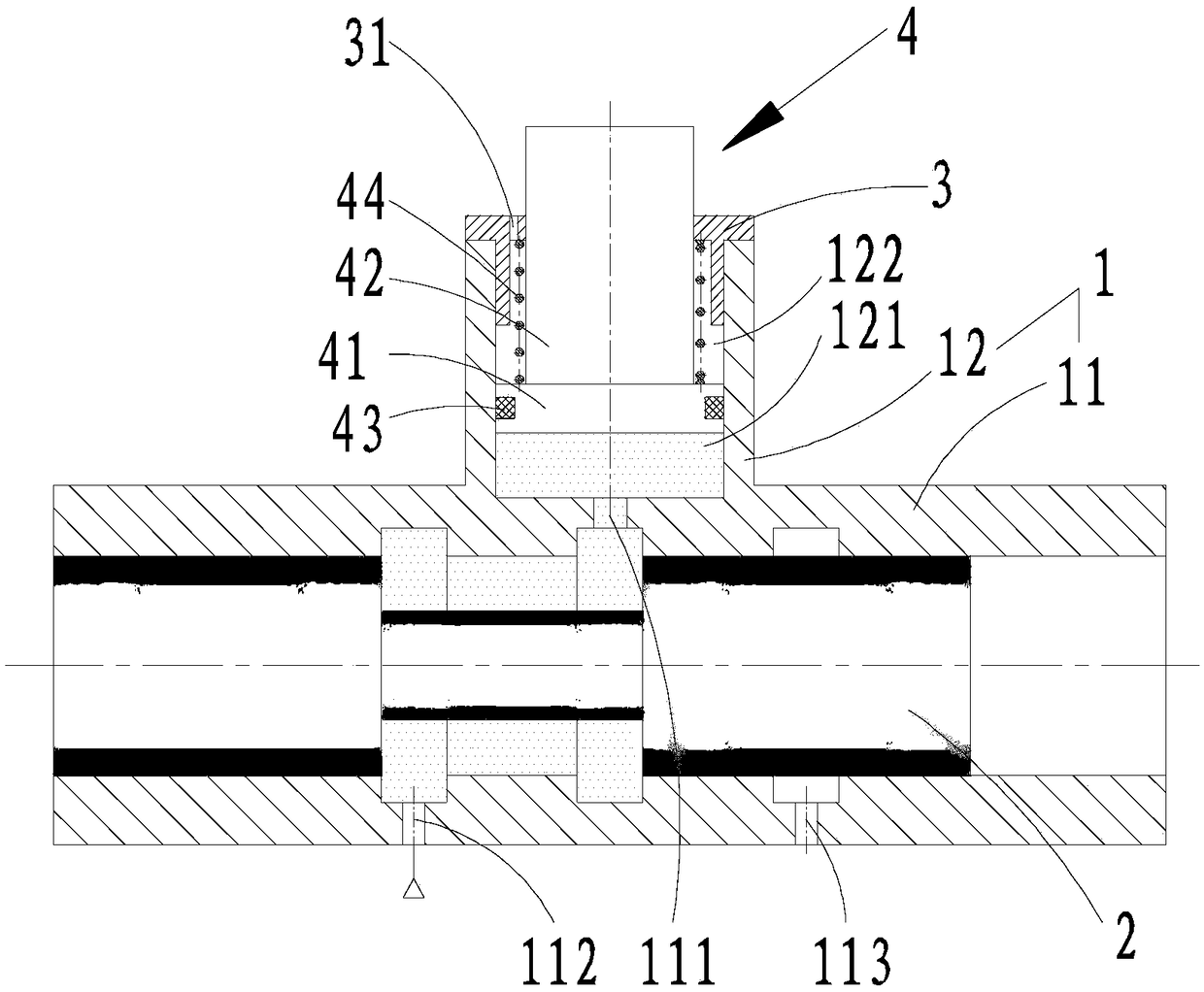

[0059] see Figure 4 In the valve-cylinder integrated component shown, in this embodiment, the reversing valve is a two-position five-way reversing valve, forming a double-acting valve-cylinder integrated component. Specifically, see Figure 4 As shown, the valve body 11 of the two-position five-way reversing valve has a flow control A port 111, a flow control B port 116, a P port 112, a T1 port 114, and a T2 port 115; the cylinder end cover 3 seals the piston hole, and the piston rod Between 42 and the piston rod hole that offers on the cylinder end cover 3, fit through the piston rod sealing ring 45 to slide and seal. Rod chamber 122 (pull action chamber) and rodless chamber 121 (thrust action chamber) alternately communicate with the flow control A port 111 and the flow control B port 116, forming a double cylinder between the actuator 2 and the piston hole. Force output device.

[0060] The working process of the double-acting valve-cylinder integrated component is: F...

Embodiment 3

[0062] see Figure 5 shown, for the Figure 4 The modification of the shown embodiment 2 is specifically that a compression spring 44 is also provided in the rod cavity 122, and the compression spring 44 is a high-rigidity compression spring, which causes it to be different from the Figure 4 The valve-cylinder integration shown works in a completely different manner, resulting in a double-acting valve-cylinder integration capable of approximately twice the output pull.

[0063] For example, Figure 4 When the shown valve-cylinder integrated component is in a non-working state, the position of the spool 2 is arbitrary, either right or left. and Figure 5 The shown double-acting valve-cylinder integrated component, in the non-working state, the valve core 2 is in the right position, and the piston 41-piston rod 42 is in the lowermost original position under the thrust of the high-rigidity compression spring 44 .

[0064] When starting to work, the valve core 2 is switched t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com