Vehicle-mounted folding retractable type down-the-hole drill

A down-the-hole drilling rig and telescopic technology, which is applied in drilling equipment, underwater drilling, earth-moving drilling, etc., can solve problems such as low efficiency, high requirements, and self-importance, so as to improve operation efficiency, reduce personnel input, and save energy. The effect of time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

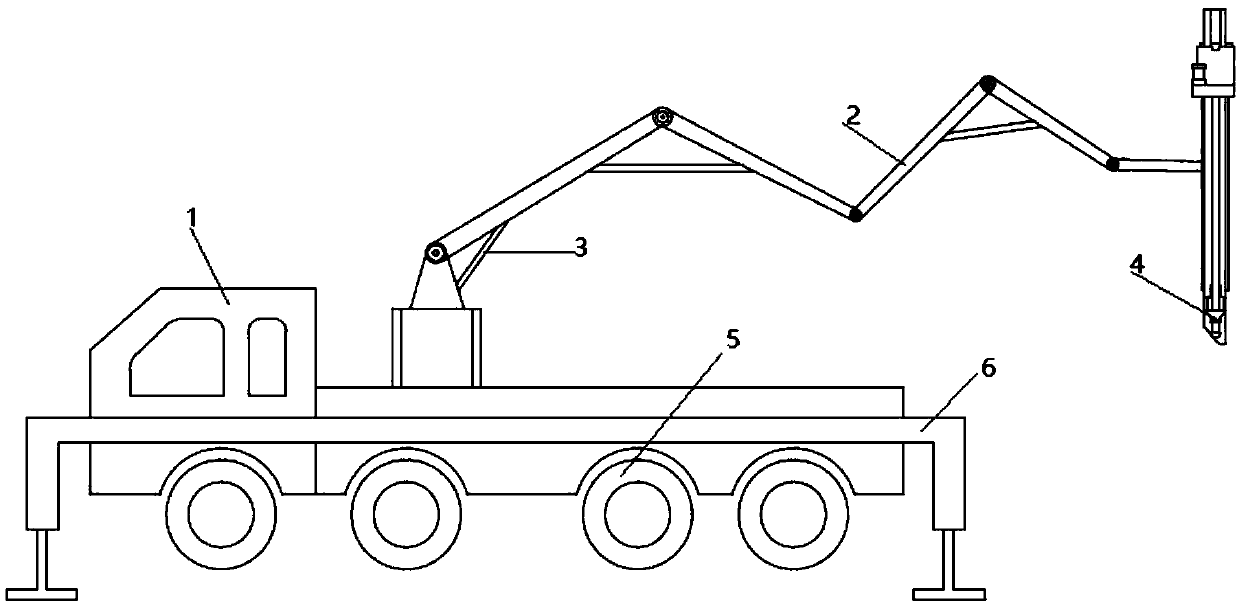

[0028] Such as figure 1 As shown, a vehicle-mounted folding and telescopic down-the-hole drilling rig includes a vehicle body, a vehicle-mounted hydraulic main pump device is arranged above the vehicle body, a folding arm is fixedly connected to the vehicle body, and the output end of the vehicle-mounted hydraulic main pump device is connected to the folding arm. The folding control device is connected, and the fully automatic drilling head system is connected at the other end of the folding arm. The length, strength, and quantity of the folding arm can be produced and manufactured according to the needs of the use site, which further facilitates the use range of the down-the-hole drilling machine. By installing other components on the top of the car body, the overall movement and handling of the down-th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com