LED plant joint growth lamp unit module and joint manner thereof

A unit module and splicing technology, applied in the field of plant growth lamps, can solve problems such as the inability to meet the needs of plant growth, and achieve the effect of saving production costs and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and with three embodiments the present invention will be further explained:

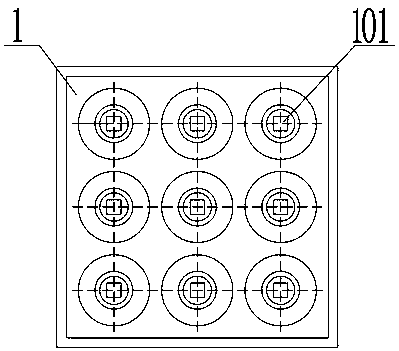

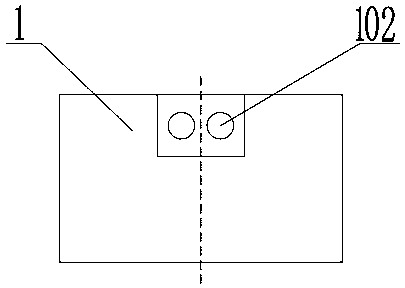

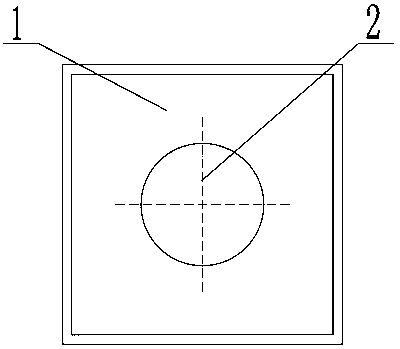

[0040] as attached figure 1 , 2 , 3, the unit modules 1a, 1b, 1c, 1n, 1n+1 include a lamp housing 1 and an LED light source 101, the housing 1 is a three-dimensional rectangle, the top surface of the three-dimensional rectangle is the mounting surface, and one or more The spectrum of LED chipsets, the number of LED light sources 101 is nine, which are arranged on the bottom surface of a three-dimensional rectangle, and arranged in matrix along the bottom surface; the four sides of the housing 1 are respectively provided with power supply and data ports 102 .

[0041] attached Figure 4 with 5 It is the compact splicing method of Embodiment 1 of the present invention, which adopts several straight-through connectors 3 to connect unit modules 1a, unit modules 1b, unit modules 1c, ..., unit modules 1n and unit modules 1 n+1Stitching into the posi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap