A dual-purpose microstructure freezing and heating sampler and cutting device

A sampler and heater technology, which is applied to the field of dual-purpose microstructure freezing and heating samplers and cutting devices, can solve the problem of not being able to extract fluid plastic and soft plastic soil samples at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

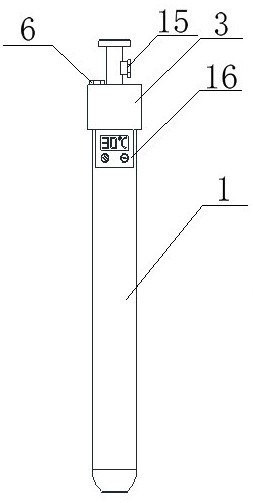

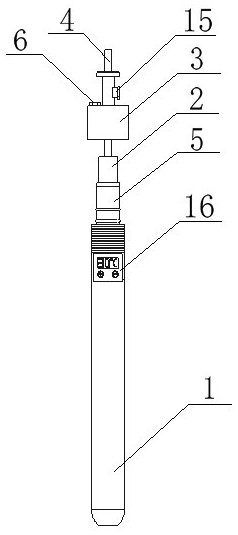

[0029] see Figure 1-Figure 6 Shown:

[0030] A dual-purpose microstructure freezing and heating sampler and cutting device is composed of a sampler and a cutting device, the sampler includes a sampler outer wall 1, a sampler inner wall 2, a sampler upper cover 3, a piston push rod 4 and a heating 5, the outer wall of the sampler 1 set is arranged outside the inner wall 3 of the sampler, a hollow interlayer is formed between the outer wall 1 of the sampler and the inner wall 2 of the sampler, and the outer wall 1 of the sampler is sealed and connected with the lower end of the inner wall 2 of the sampler; the inner wall of the sampler 2 The upper and lower ends are open, and the inside is connected; the sampler upper cover 3 is arranged on the upper end of the sampler outer wall 1, and the upper end of the sampler upper cover 3 is provided with a push rod through hole, and the described piston push rod 4 is arranged on Inside the inner wall of the sampler 2, the upper end pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com