Upper threading and lower incoming stator winder

A wire stator and winding machine technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high labor intensity, inability to realize automation, low efficiency, etc., and achieve high winding efficiency and stable work. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

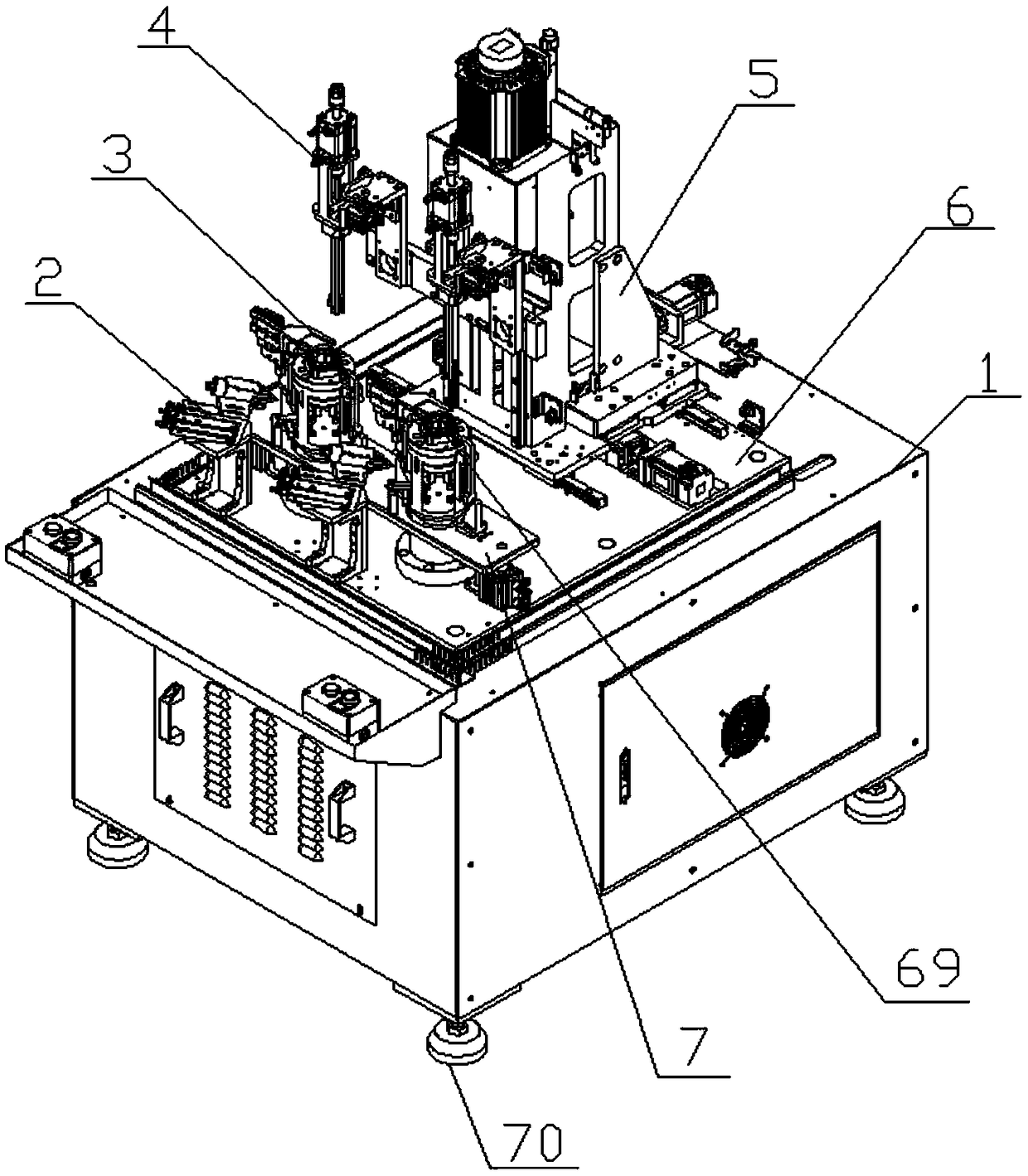

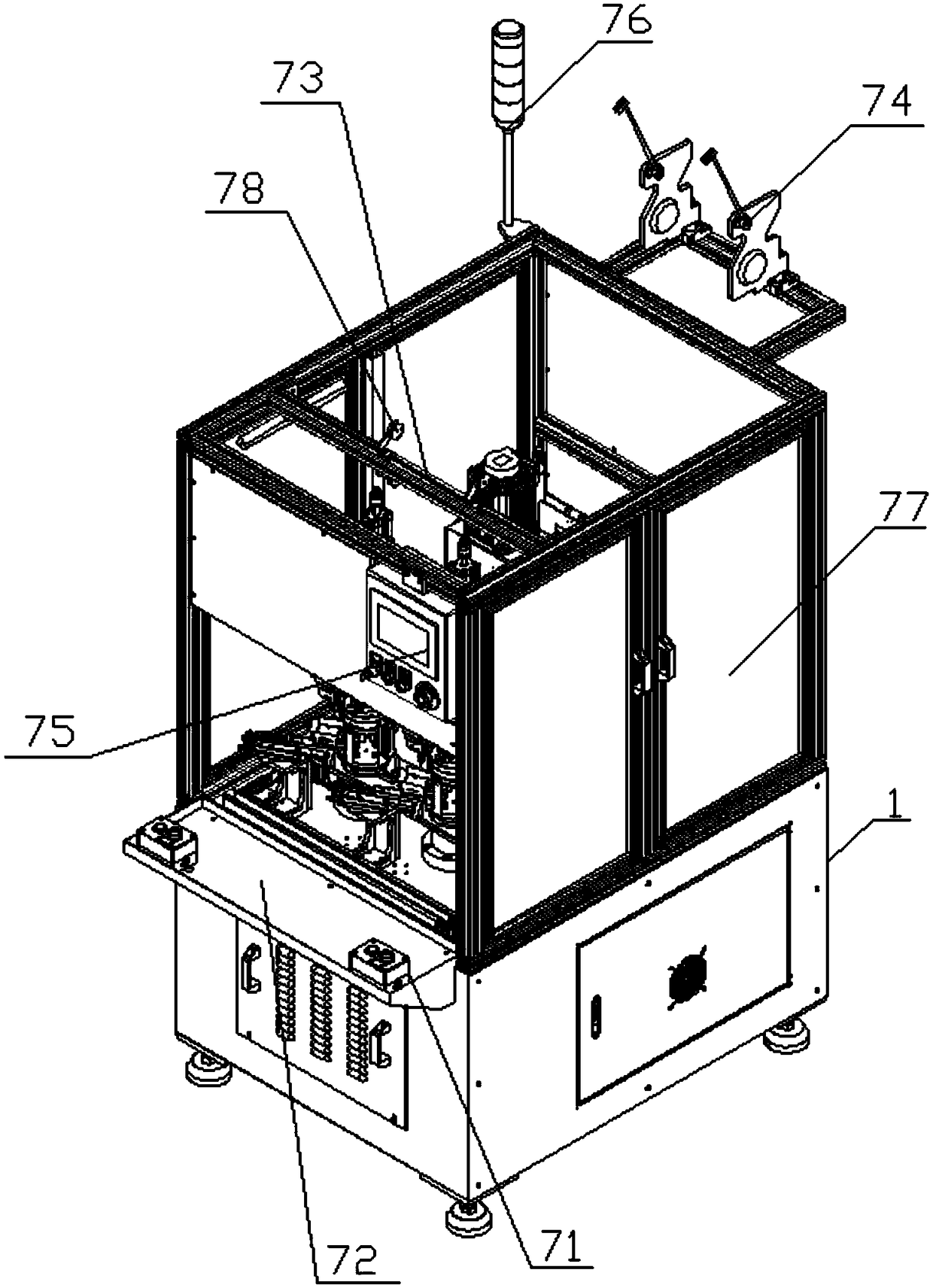

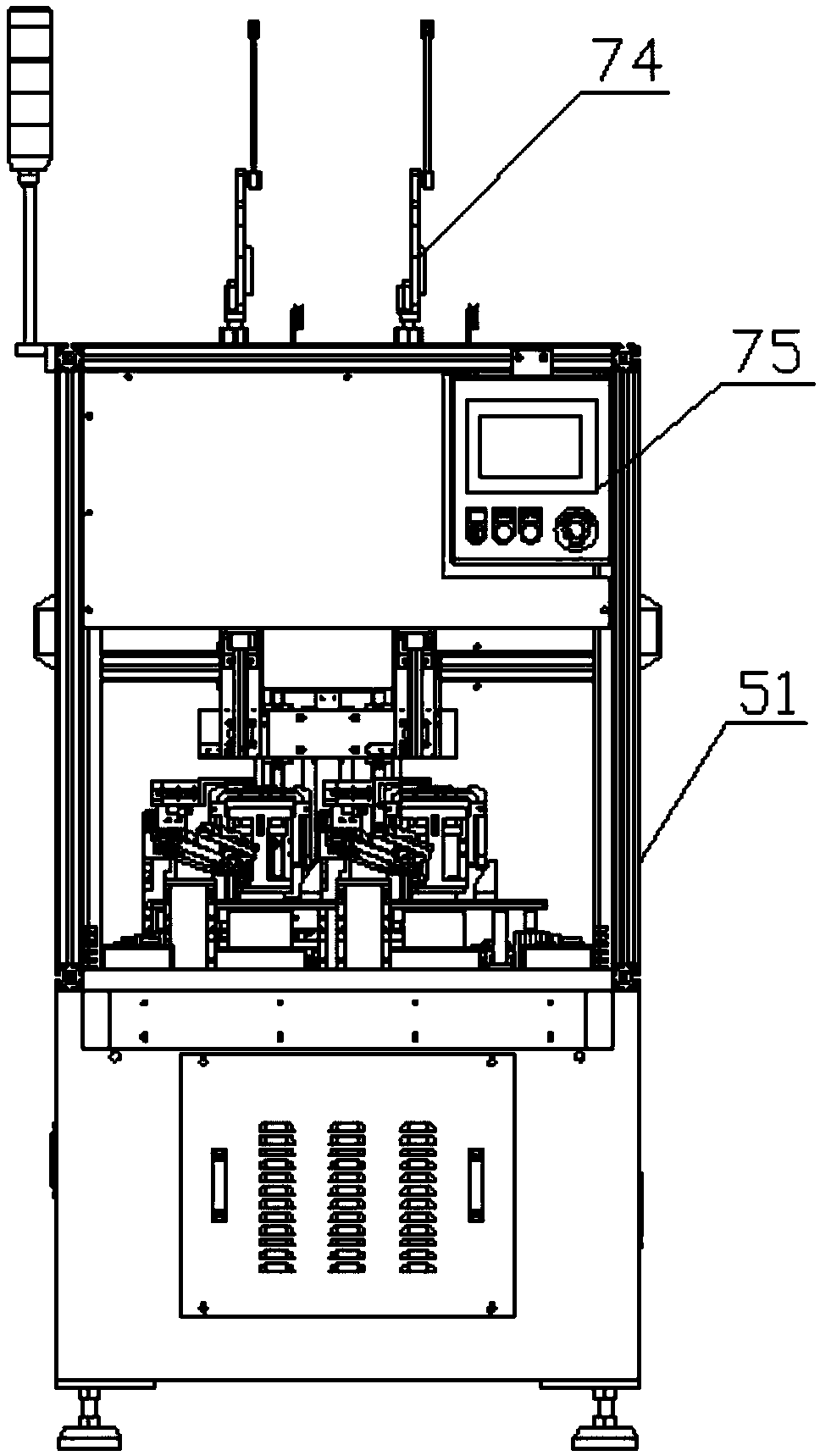

[0037] refer to Figure 1 to Figure 11 The shown stator winding machine includes a chassis assembly 1, a scissors assembly 2, a wire protection assembly 3, an upper and lower wire assembly 4, a three-dimensional assembly 5, a large bottom plate 6, and a loose clamp Assembly 7 and shield assembly 51, the large bottom plate 6 is installed directly above the chassis assembly 1, the lower end of the chassis assembly 1 is provided with a support foot 70, the scissors assembly 2, the wire protection assembly 3, and the upper and lower wires Component 4, three-dimensional component 5, large base plate 6 and loose clamp component 7 are installed on the large base plate 6, scissors component 2, wire protection component 3, wire entry component 4, three-dimensional component 5, large base plate 6 and loose clamp A shield assembly 51 is provided around the outer side of the assembly 7, the lower end of the shield assembly 51 is connected to the chassis assembly 1, and a forwardly protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com