Multi-joint bionic mechanical chela pincer with autonomous hydraulic power distribution function

A bionic machinery and hydraulic power system technology, applied in the field of intelligent bionic robots, can solve the problems of inconvenient installation and maintenance, single movement mode, less degrees of freedom, etc., to reduce external energy requirements, easy installation and disassembly, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

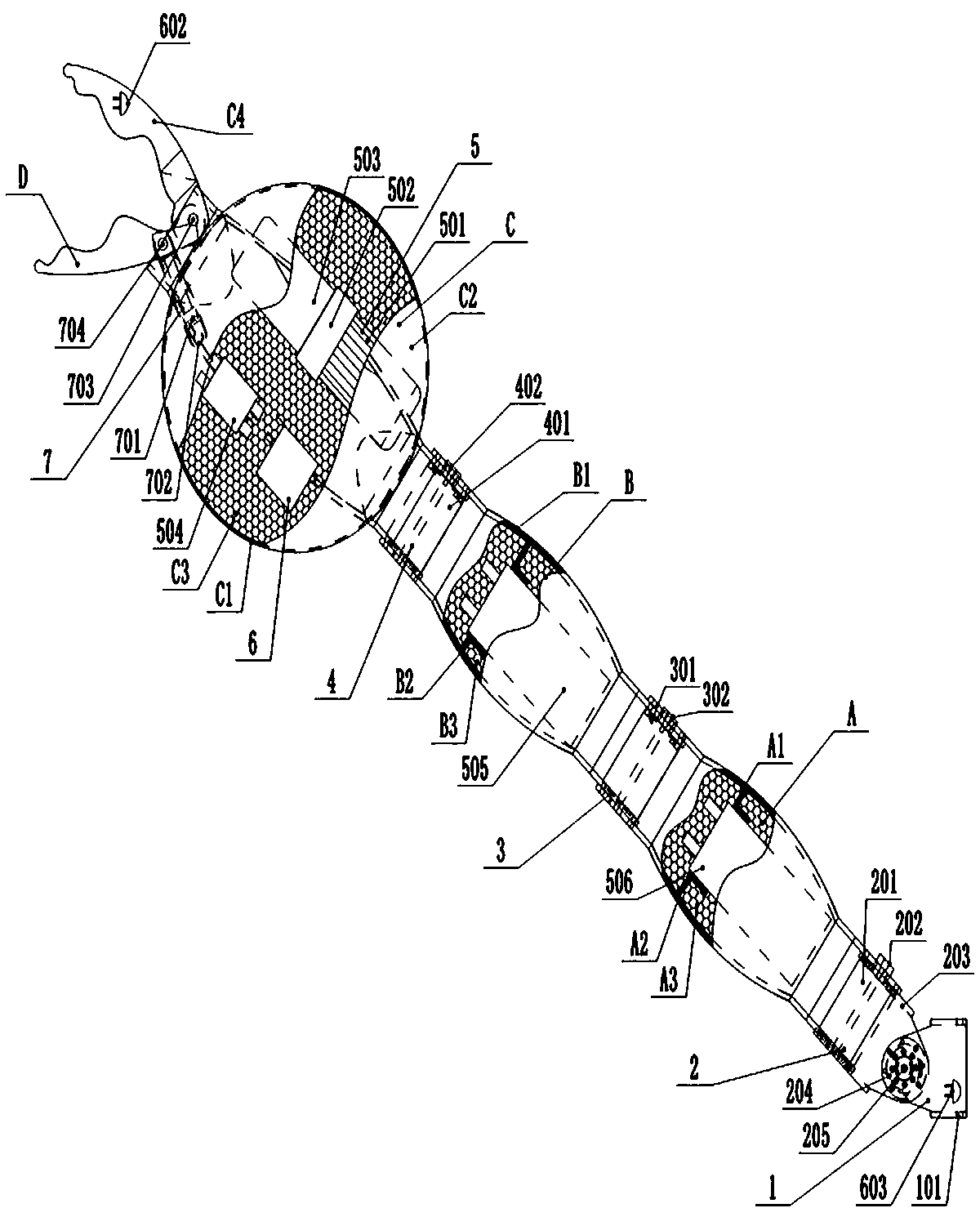

[0032] refer to figure 1 , figure 2 In this embodiment, the multi-joint bionic mechanical pliers with independent hydraulic power distribution mainly includes a connecting frame 1, a three-dimensional joint 2, a claw joint A, a two-dimensional joint I3, a claw joint B, a two-dimensional joint II4, a claw-shield joint C, Clamp moving device 7, clamp joint D, integrated hydraulic power system 5, intelligent electric control device 6; the three-dimensional joint 2 is fixed on the connecting frame 1 and connected with the jaw joint A, and the jaw joint A is connected with the jaw joint B through the two-dimensional joint I3 , the chela-shield B is connected with the chela-shield C through the two-dimensional joint II4, and the chela-shield C is connected with the chela-shield D through the clamp device 7, and the integrated hydraulic power system 5 is fixed on the claw A, the claw B and the claw-shield C In the cavity, it is respectively connected with the hydraulic ports of the...

Embodiment 2

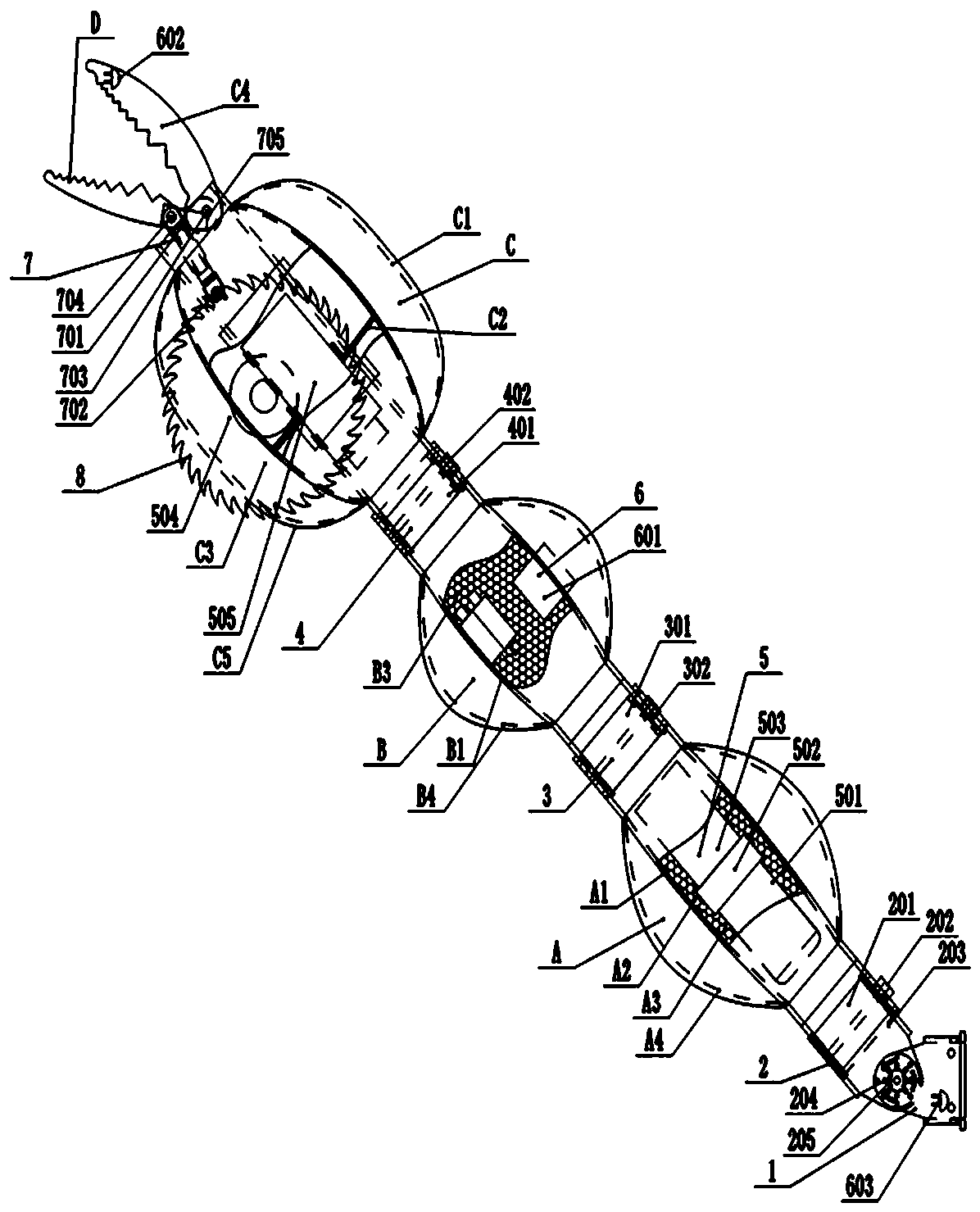

[0040] refer to image 3 , Figure 4 , the multi-joint bionic mechanical pincers with independent hydraulic power distribution in this embodiment differs from Embodiment 1 only in that: the mechanical pincers are additionally provided with a circular saw 8, which is fixed at the middle and lower part of the pincer-shield joint C; The connecting frame 1 adopts the form of a card slot and a fixed pin hole for quick connection; the claw joint A and the claw joint B are special-shaped components made of titanium alloy with cavities; wherein the outer surfaces of the claw joint A and the claw joint B are also provided with There are solar film parts ⅠA4 and solar film parts ⅡB4, which are used to collect solar energy to supply power to the bionic legs; the ends of the claw joint A and the claw joint B are provided with elastic stretchable protective sleeves A5 and elastic stretchable protective sleeves B5 for joint protection; the claw joints The shield section C adopts a shield s...

Embodiment 3

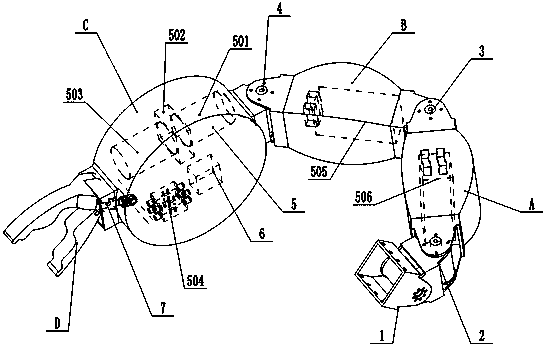

[0042] refer to Figure 5 , Image 6 , the difference between the multi-joint bionic mechanical pliers with independent hydraulic distribution power in this embodiment and embodiment 1 is only that a chain saw 8 is added on the mechanical pliers, which is fixed in the middle part of the claw-shield joint C; the chain saw 8 includes a drive motor 801, a chain saw disc 802, and a swing cylinder 803, wherein the swing cylinder 803 controls the swing of the chain saw disc 802, and when the chain saw is not working, the chain saw disc swings to the side of the upper jaw C4. The upper clamp section C4 and the clamp section D form a clamp, which is driven by the clamp hydraulic cylinder 701 to clamp the object, and is sawed off with the chain saw 8; the power device 5 is arranged in the claw section A, and Claw-shield joint C adopts shield type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com