Gear synchronous displacement modular expansion joint

A technology of synchronous displacement and expansion joints, applied to bridge parts, bridges, buildings, etc., can solve the problems of easy damage, uneven force, etc., and achieve the effect of convenient maintenance and disassembly, low cost and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

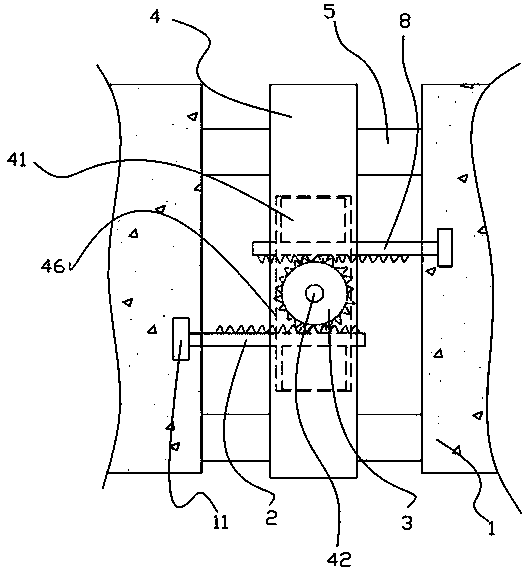

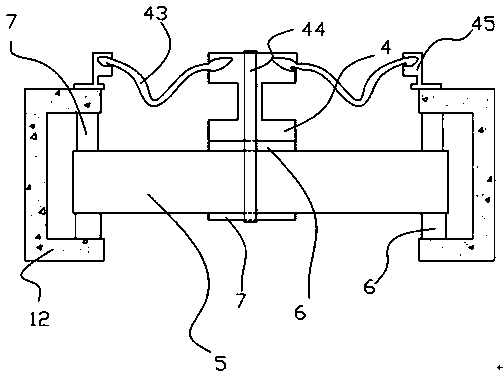

[0030] Example 1 A Gear Synchronous Displacement Modular Expansion Joint

[0031] This embodiment is a gear synchronous displacement modular expansion joint, which is installed in the gap between two existing bridge bodies 1, such as figure 1 As shown, it comprises the bridge main bodies 1 that are set apart, namely the left and right bridge body main bodies 1 in the figure, the middle is an expansion gap, and the bottom of the left and right bridge body main bodies 1 is respectively provided with displacement boxes 12 (beam body main body 1, The displacement boxes 12 are existing devices, and the positional relationship between them and the connection mode are also existing technologies), and two relative displacement boxes 12 are provided with a bridge spanning the expansion gap between the two bridge main bodies 1. The horizontal beam 5 extending along the length direction of the bridge body 1 can be provided with a plurality of displacement boxes 12 and beams 5 according t...

Embodiment 2

[0038] Embodiment 2 A gear synchronous displacement modular expansion joint

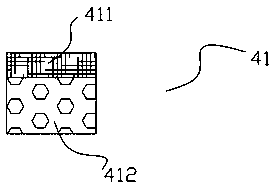

[0039] This embodiment is a gear synchronous displacement modular expansion joint, the specific structure is similar to that of Embodiment 1, the only difference is that it includes two or more sets of expansion joint sliding connection devices connected in series, that is, it includes two or more sets The first rack 2, the ball bearing 42, the second rack 8, and the gear 3. In practical applications, when the expansion gap is large, several middle beams 4 need to be provided, and the lower surface of each middle beam 4 is provided with a gear protection box 46, and the gear protection box 46 is provided with a first rack 2, a ball bearing 42. The second rack 8, the gear 3 and the buttress 41, a rack is shared between two adjacent middle beams 4, and each middle beam 4 is equipped with a gear 3, and two or more sets of them are connected in series. When the expansion joint slides the connection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com