Connecting column of right-angle concrete premix compound

A technology for connecting columns and premixed materials, applied to building components, ceramic molding machines, walls, etc., can solve problems such as low strength, easy to be affected by moisture, easy to crack, etc., and achieve the goal of improving construction efficiency, raising curing temperature, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

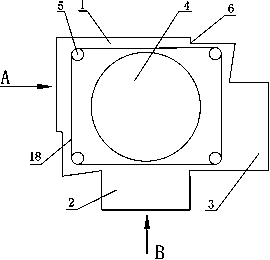

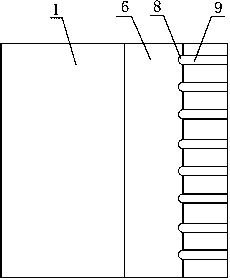

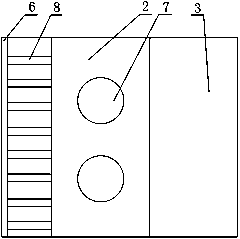

[0042] Such as Figure 4 As shown, the outer wall panel 11 and the inner wall panel 12 are clamped on both sides of joint one 2 and joint two 3 during use, and caulking grooves 6 are provided on the outer wall surface. Adhesive 14 until the adhesive 14 fills the vertical grouting groove 8 , the horizontal grouting groove 9 and the caulking groove 6 . After the grouting is finished, use the caulking tape 13 to lay in the caulking groove 6, and the adhesive 14 in the caulking groove 6 is smoothed and solidified, so as to prevent the wall from slit along the junction of the joint one 2 and the connecting column 1.

[0043] After the construction is completed, the electric wires 16 in the building can be laid through the passing through the wire hole 7 and the through hole 4 of the connecting column 1 in the outer wall panel 11 and the inner wall panel 12 as required, and can also pass through the auxiliary hole 10 and the through hole 4 To achieve cross-floor cable laying.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com