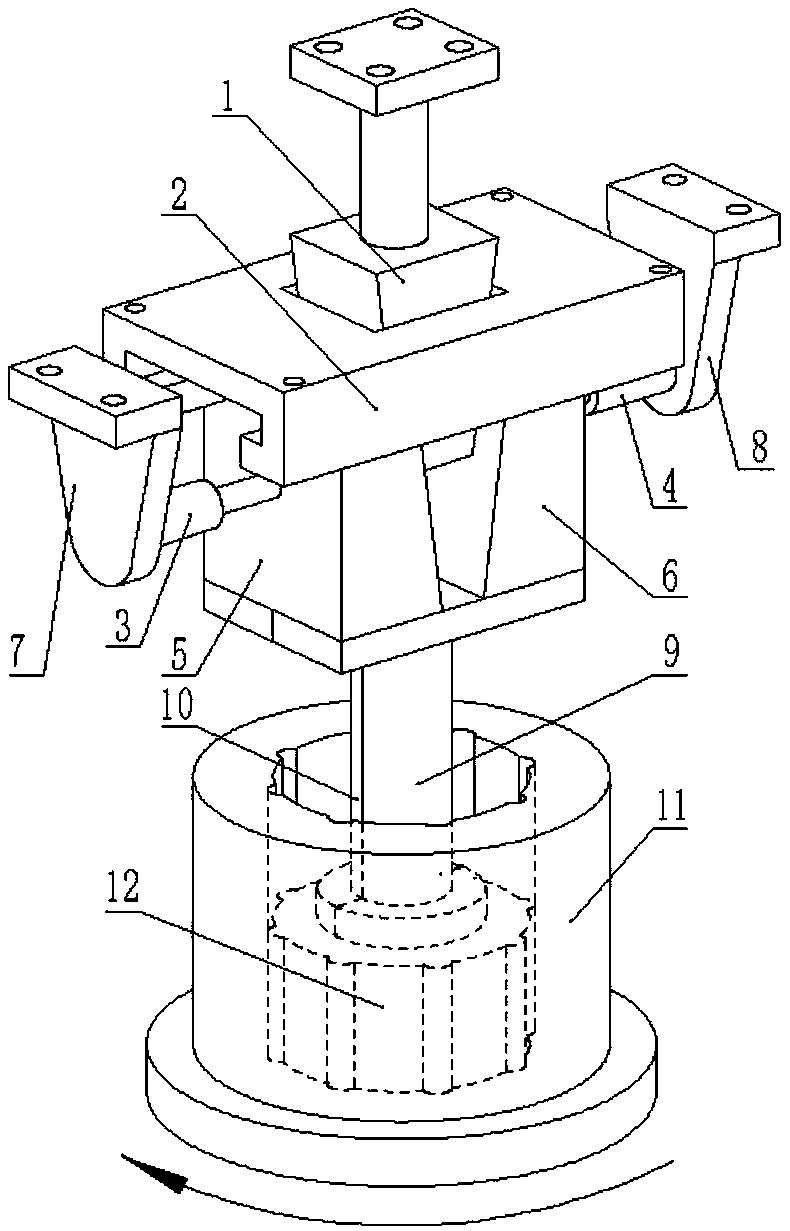

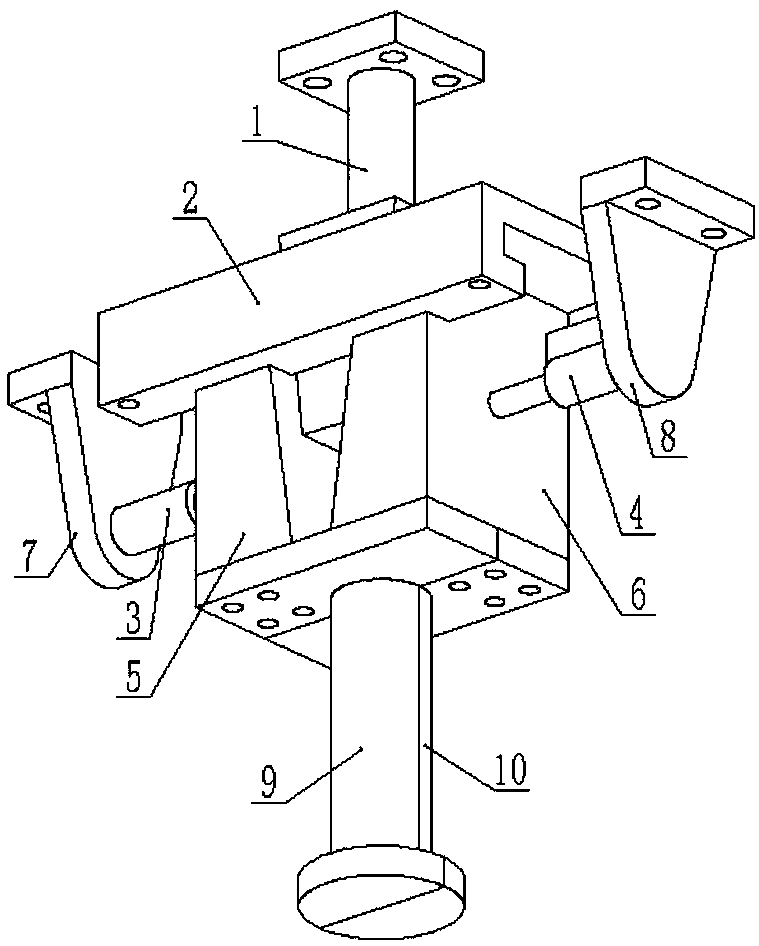

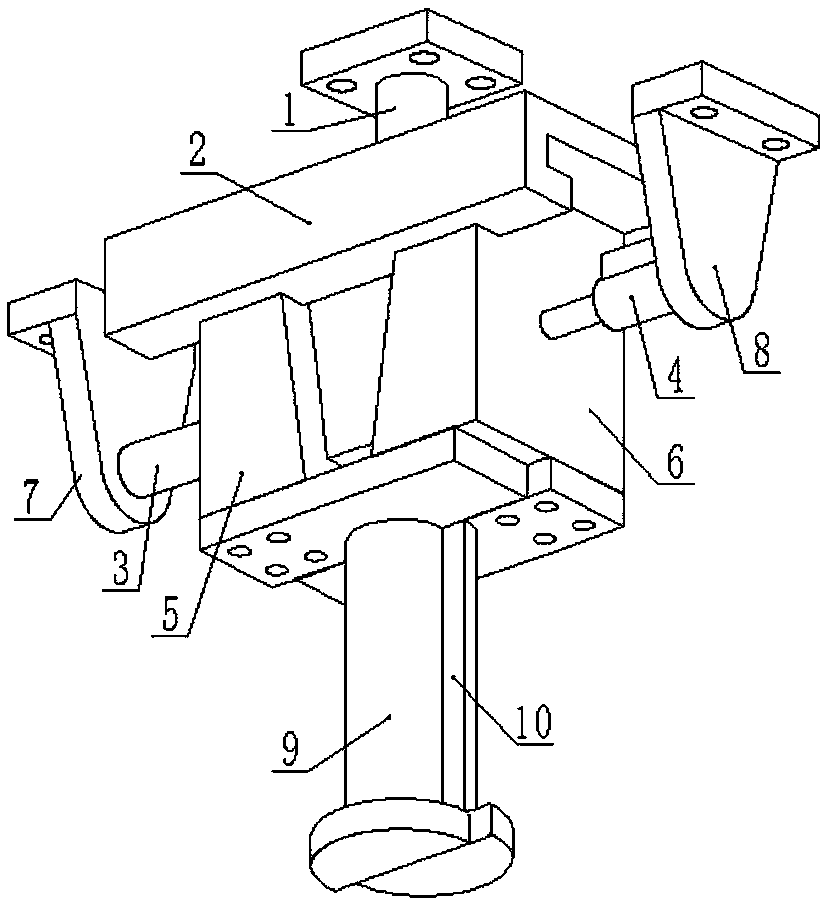

Parallel die parting multidirectional loading rotary extrusion forming die and die opening method

An extrusion forming and multi-directional loading technology, which is applied in the field of forming molds for cylindrical parts, can solve the problems that the internal streamline of the material affects the mechanical properties and service life, it is difficult to realize processing, and the material utilization rate is low, so as to achieve the preform process Convenience and simplicity, less machining allowance and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take the cylindrical part 14 that can be formed by the mold involved in the present invention with an inner ring rib at the port and a stepped inner ring rib in the middle along the central axis as an example, the cross section of the part is as follows Figure 4 shown, combined with Figure 5-7 The forming process will be described.

[0043] Use a solid bar with a diameter greater than or equal to the inner diameter of the die plus twice the inner wall groove of the cylindrical part along the radial direction as the blank. The length of the blank can be obtained according to the principle of constant volume before and after forming. The solid billet is machined into a preform whose cross section is consistent with the cross section of the concave mold cavity perpendicular to the central axis, and the preform is put into the concave mold. according to Figure 5 Process as indicated by the middle arrow:

[0044] First, according to Figure 5 As shown in the first pictu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com