Automatic sharpening device for grinding wheel

A grinding wheel, automatic technology, used in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve the problems of substandard cutting edge machining accuracy, grinding wheel dressing, grinding wheel flatness and sharpness reduction, etc. Achieving quick and effective adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

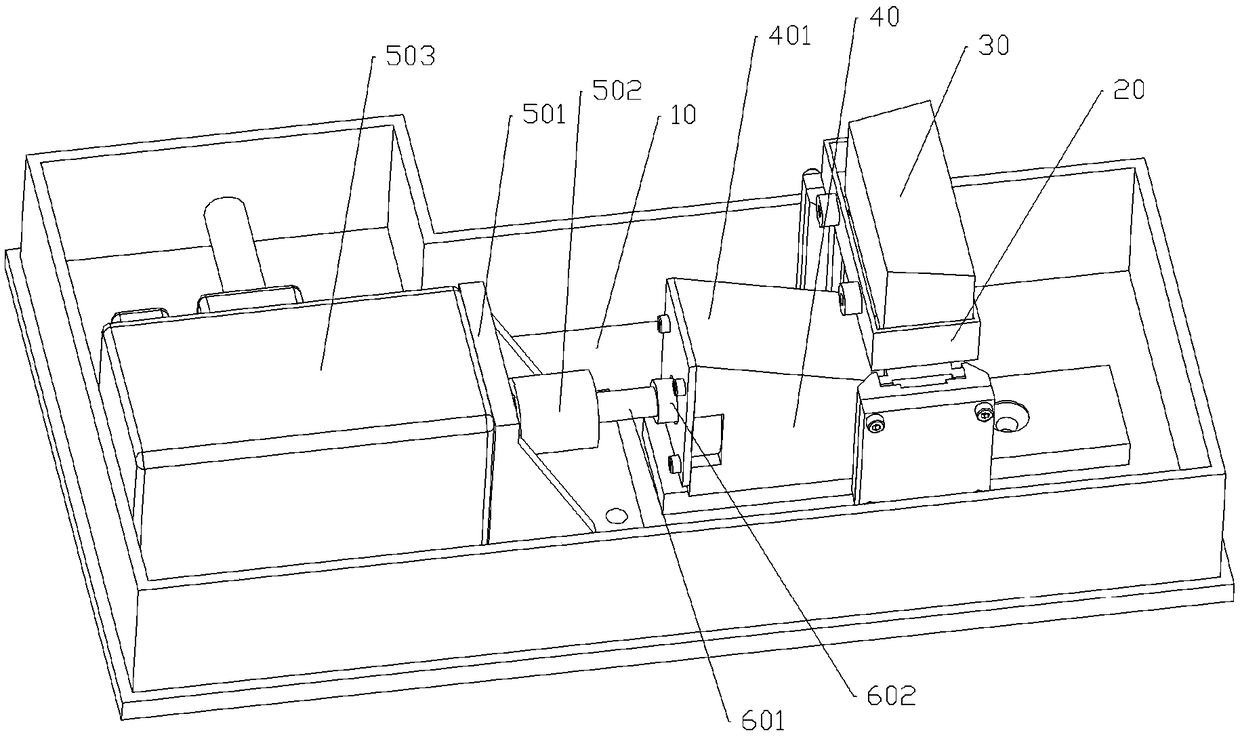

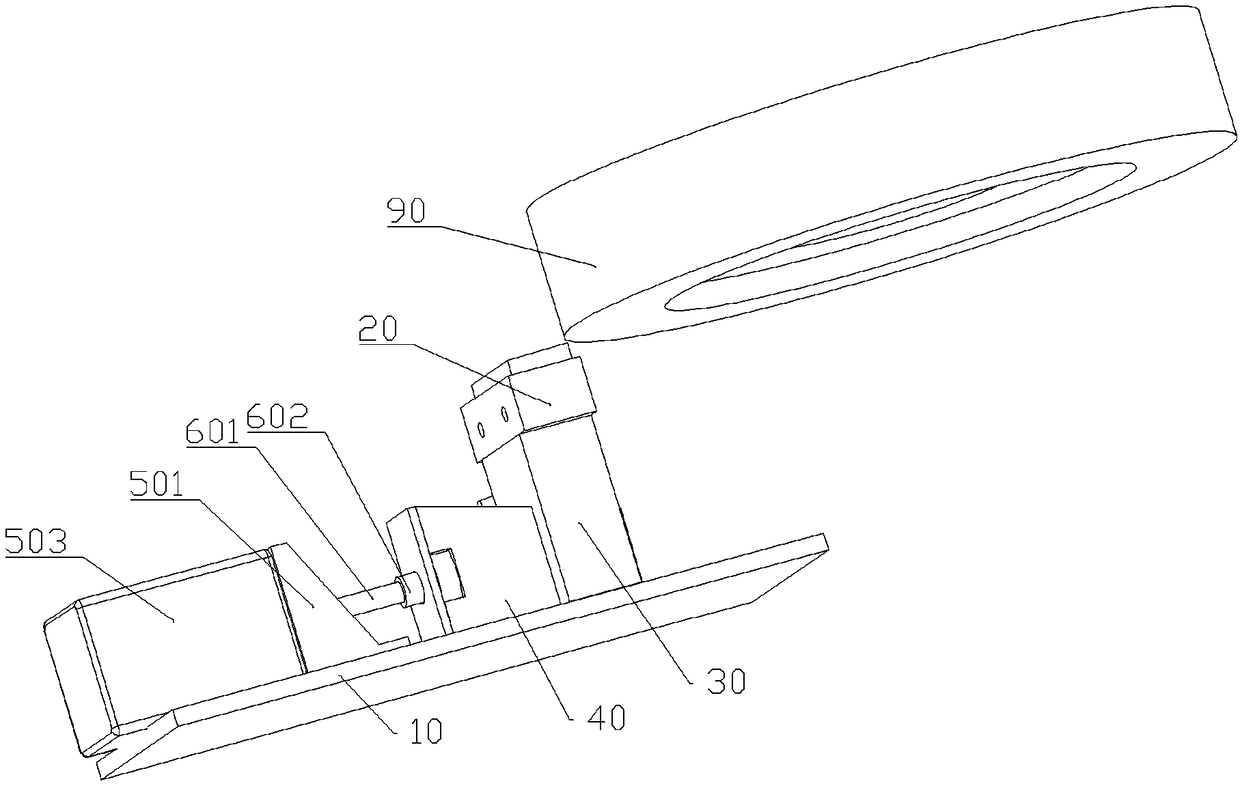

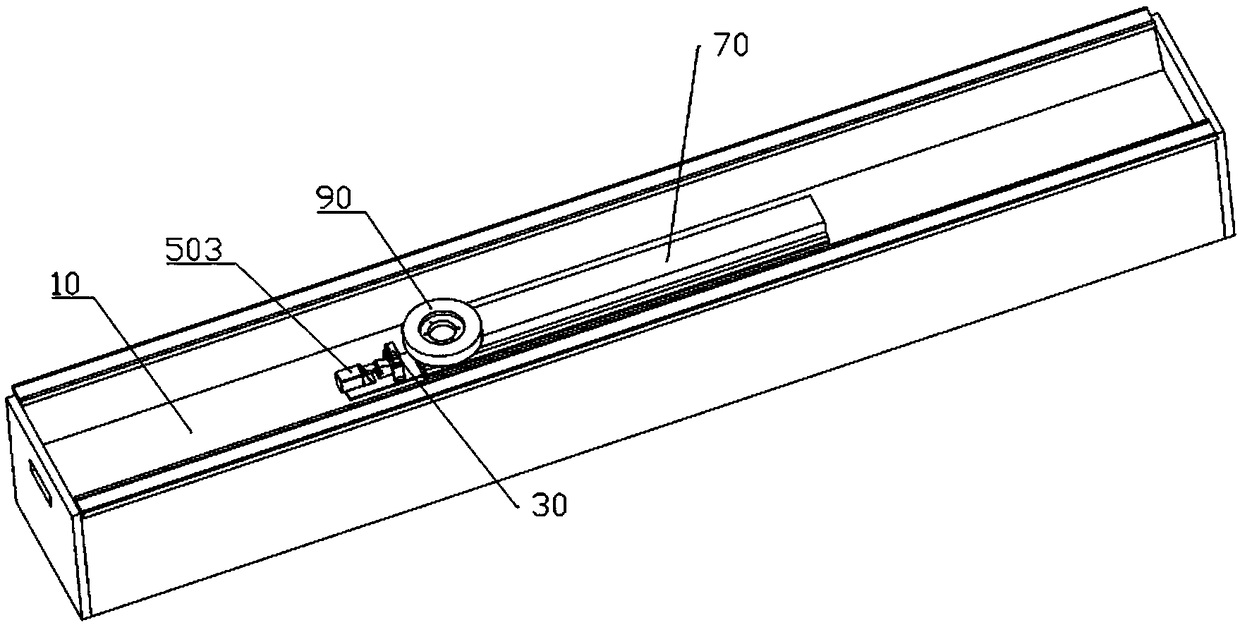

[0029] Embodiment 1 is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: an automatic grinding device for grinding wheels, including a frame and a grinding mechanism, the frame includes a bottom plate 10 and a cage 20, and the cage 20 is fixed on the frame by bolts and nuts 602.

[0030] Such as figure 1 As shown, the grinding mechanism includes a trimming block 30, a top block 40, a reducer 501, a coupling 502, a screw 601, a nut 602 and a servo motor 503, the servo motor 503, a reducer 501, a coupling 502, a screw 601 and nut 602 are arranged in turn from left to right, the left end of the screw rod 601 is coaxially fixedly connected with the right end of the shaft coupling 502, the left end of the shaft coupling 502 is fixedly connected with the right end of the speed reducer 501, and the right end of the speed reducer 501 is connected with the servo The motors 503 are coaxially fixedly installed.

[0031] The trimming block 30 is in the s...

Embodiment 2

[0040] Embodiment 2 is basically as attached Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that a rubber sheet 402 is fixedly installed on the slope 401 of the trimming block 30, the rubber sheet 402 is in contact with the trimming block 30, and the bottom surface of the trimming block 30 is bonded to the rubber sheet 402, To facilitate the top block 40 when pushing the trimming block 30 to move up, the trimming block 30 is fed stably; as Figure 4 As shown, the upper end of the cage 20 is provided with a collection mechanism, the collection mechanism includes a bowl-shaped collection tank 801 and a number of brushes 802, the center of the collection tank 801 passes through the cage 20, and the collection tank 801 is buckled with the cage 20 Connected, the brush 802 is fixedly bonded on the upper surface of the collection tank 801 , and the brush 802 is in contact with the lower surface of the grinding wheel 90 .

[0041] When the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com