Injection molding machine for plastic automobile fitting production

A technology of injection molding machines and plastics, applied in applications, household components, household appliances, etc., can solve the problems of a large number of human resources, inconvenient device handling, and inability to install and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

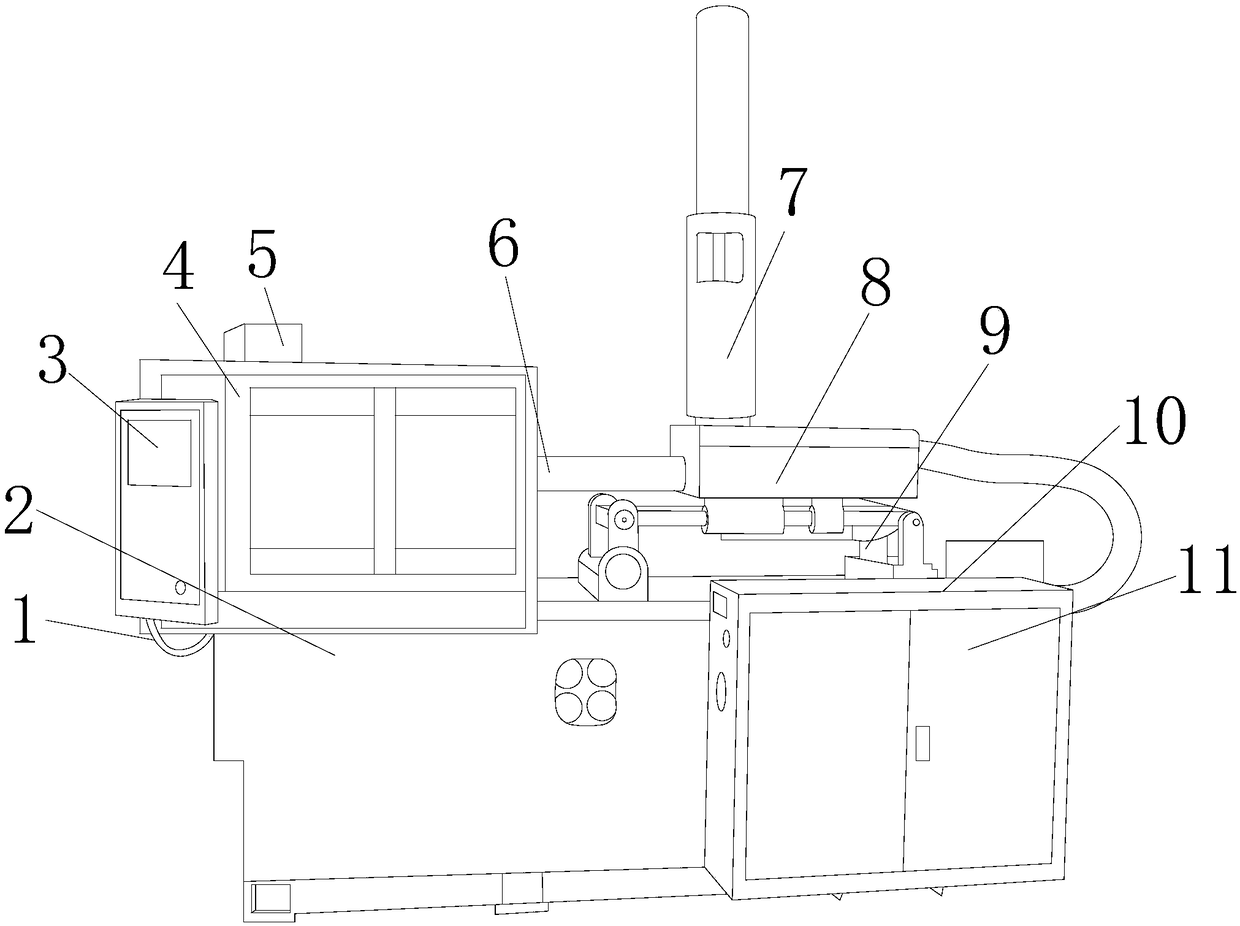

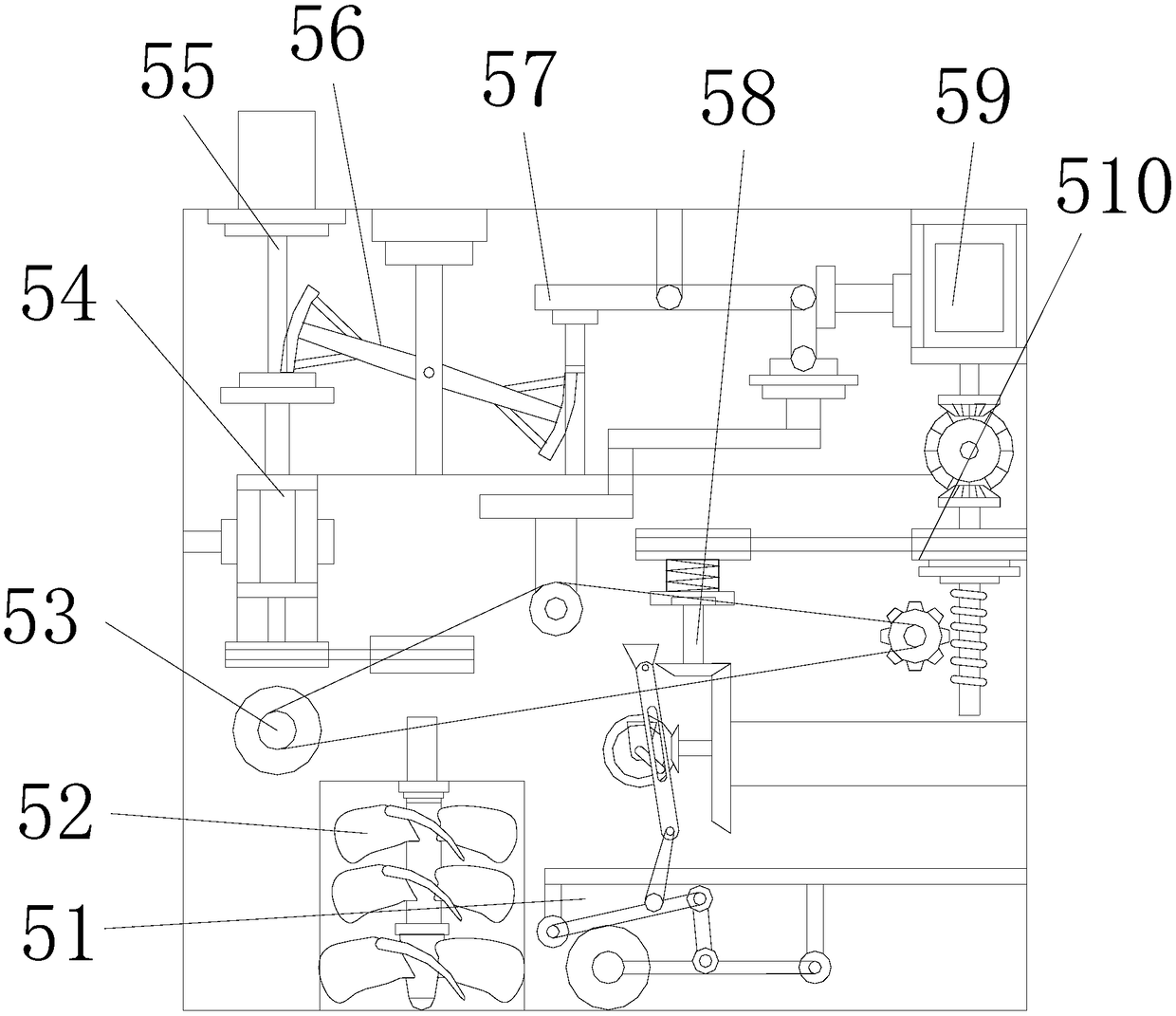

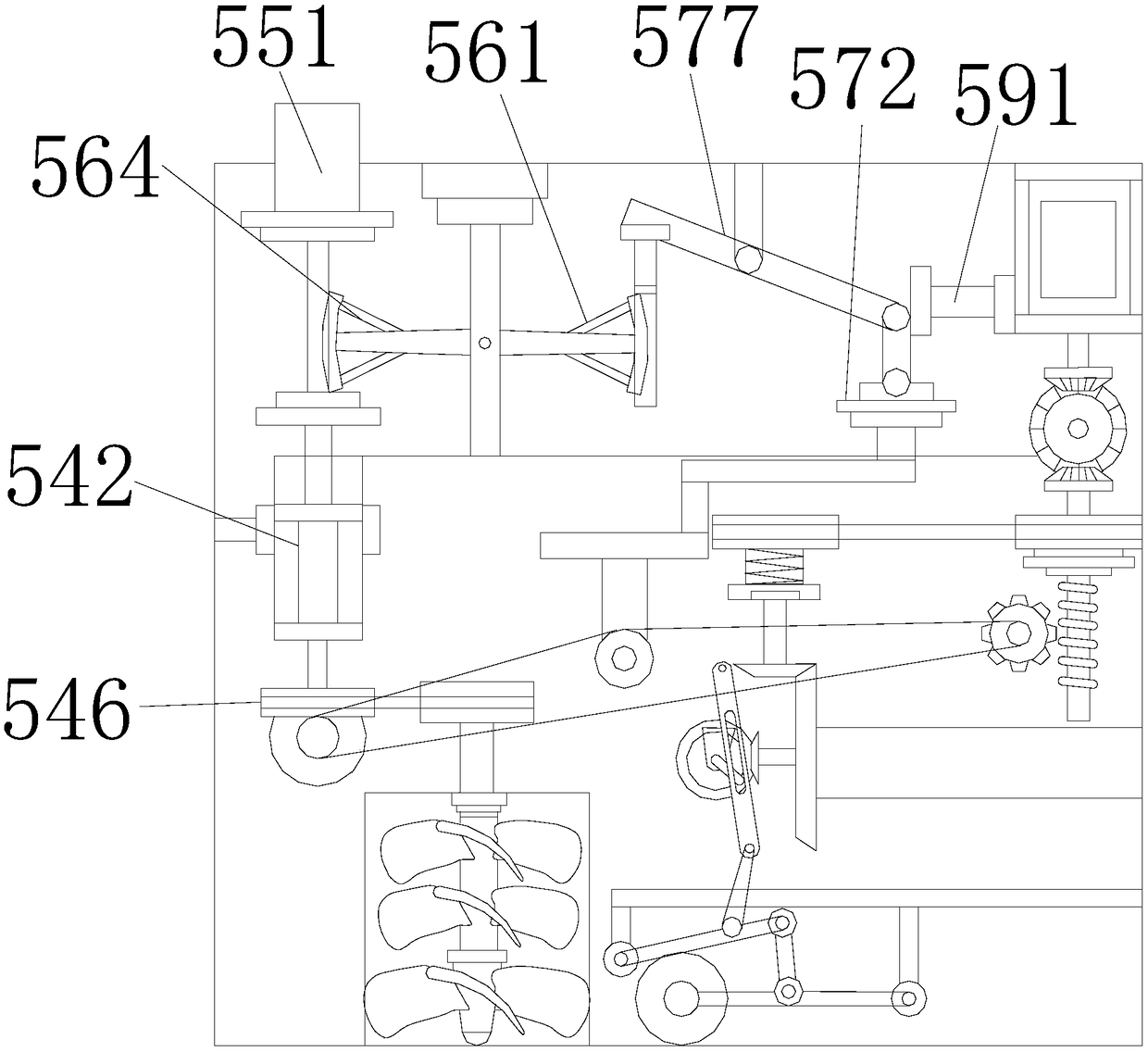

[0027] see Figure 1-Figure 5 , the invention provides an injection molding machine for the production of automobile plastic parts, its structure includes a cable 1, a body 2, an electric control box 3, an electricity storage box 4, a moving mechanism 5, a slide bar 6, a feeding bar 7, an injection box 8, and a bracket 9. The box body 10, the sliding door 11, the cable 1 is located in the electric control box 3, and the electric control box 3 is electrically connected to the cable 1;

[0028] The electric control box 3 is arranged on the electric storage box 4, the electric storage box 4 and the electric control box 3 are an integrated structure, the right side of the electric storage box 4 is provided with a slide bar 6, and the The sliding bar 6 and the electricity storage box 4 are an integrated structure, the sliding bar 6 is provided with an injection box 8, the injection box 8 and the sliding bar 6 adopt clearance fit, and the top of the injection box 8 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com