Single arm pantograph with ternary system structure

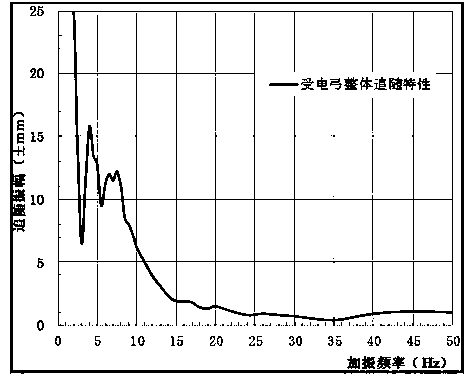

A pantograph and single-arm technology, applied in the field of pantographs, to achieve the effects of dispersing the quality of the bow head, reducing the quality of the calculation, and improving the followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

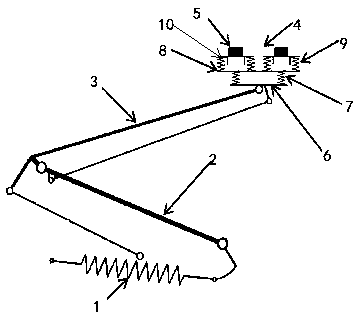

[0021] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0022] Three-element structure single-arm pantograph, including base frame, lifting bow spring 1, lower arm assembly 2, upper arm assembly 3 and bow head assembly 4, said bow head assembly 4 includes bow head bracket 6, micro Moving spring 7, connection frame 8, return spring 9, skateboard bracket 10 and slide plate 5, the bow bracket 6 is used to connect with the upper end of the upper arm assembly, and the micro-motion spring 7 is arranged on the bow bracket 6 and the connection frame 8 Among them, the return spring 9 is arranged between the connection frame 8 and the skateboard support 10; the slide plate 5 is fixed on the slide support 10; the displacement of the micro-motion spring 7 and the return spring 9 are the same. The displacement of described fretting spring 7 and recovery spring 9 is identical, specifically refers to:

[0023] The displ...

Embodiment 2

[0034] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0035] Three-element structure single-arm pantograph, including base frame, lifting bow spring 1, lower arm assembly 2, upper arm assembly 3 and bow head assembly 4, said bow head assembly 4 includes bow head bracket 6, micro Moving spring 7, connection frame 8, return spring 9, skateboard bracket 10 and slide plate 5, the bow bracket 6 is used to connect with the upper end of the upper arm assembly, and the micro-motion spring 7 is arranged on the bow bracket 6 and the connection frame 8 Among them, the return spring 9 is arranged between the connection frame 8 and the skateboard support 10; the slide plate 5 is fixed on the slide support 10; the displacement of the micro-motion spring 7 and the return spring 9 are the same. The coefficient of elasticity of the fretting spring 7 and the recovery spring 9 satisfies, K1 / K2=m1 / (2m1+m2); K2 repr...

Embodiment 3

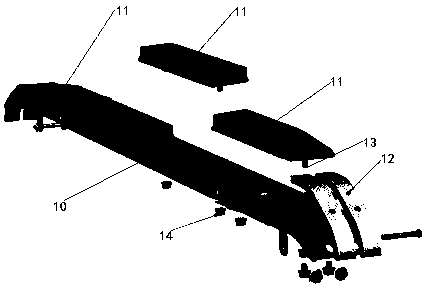

[0038] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0039] Three-element structure single-arm pantograph, including base frame, lifting bow spring 1, lower arm assembly 2, upper arm assembly 3 and bow head assembly 4, said bow head assembly 4 includes bow head bracket 6, micro Moving spring 7, connection frame 8, return spring 9, skateboard bracket 10 and slide plate 5, the bow bracket 6 is used to connect with the upper end of the upper arm assembly, and the micro-motion spring 7 is arranged on the bow bracket 6 and the connection frame 8 Between, the return spring 9 is arranged between the connecting frame 8 and the skateboard support 10; the slide plate 5 is fixed on the slide support 10; the displacement of the micro-motion spring 7 and the return spring 9 are the same; the slide plate 5 It includes several skateboard parts 11 and auxiliary skateboards 12 arranged at both ends of the skate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com