Linear plasma gun head

A plasma and gun head technology, applied in the field of ion gun heads, can solve the problems of high processing, production and maintenance costs, uneven glass surface treatment, unstable operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

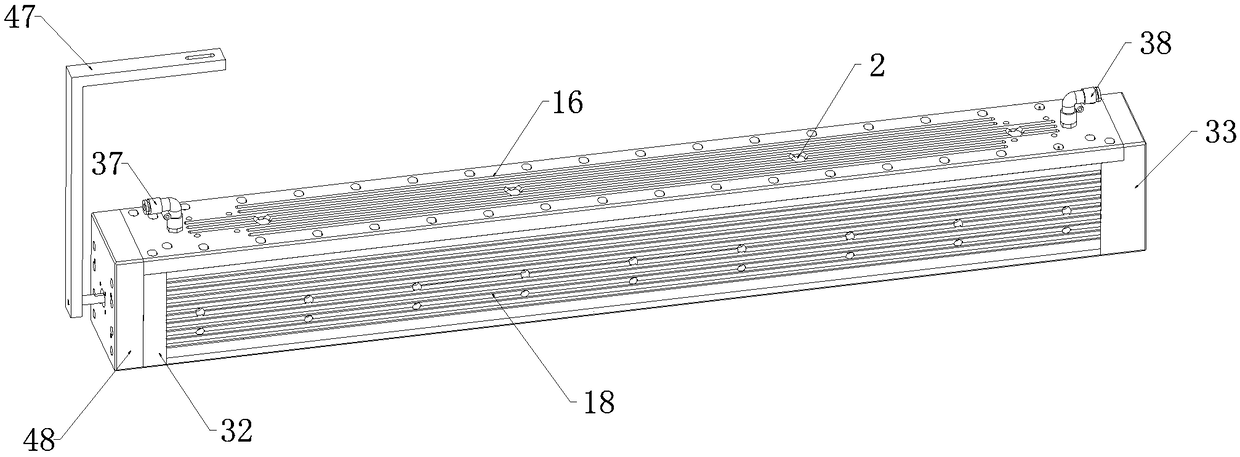

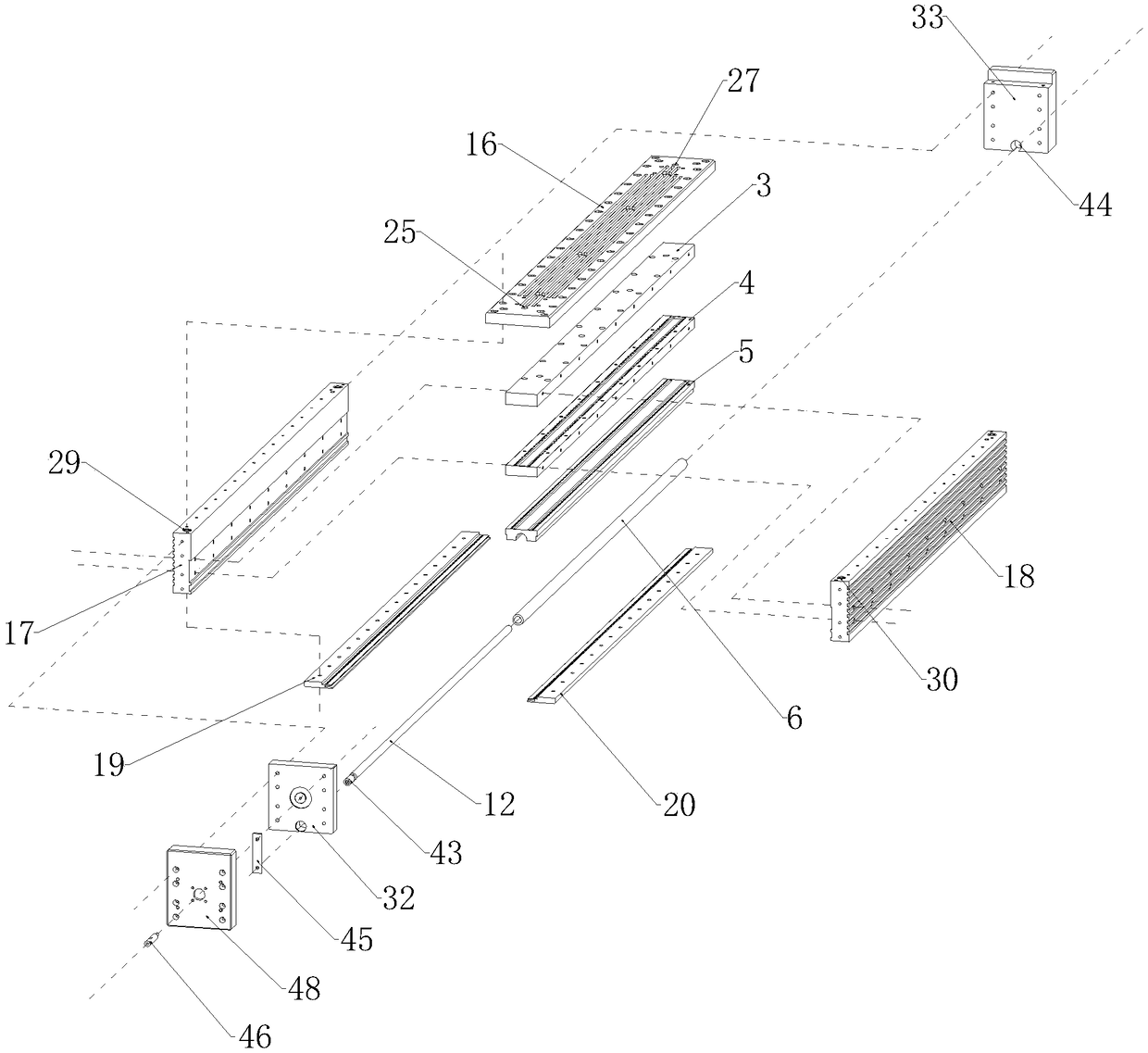

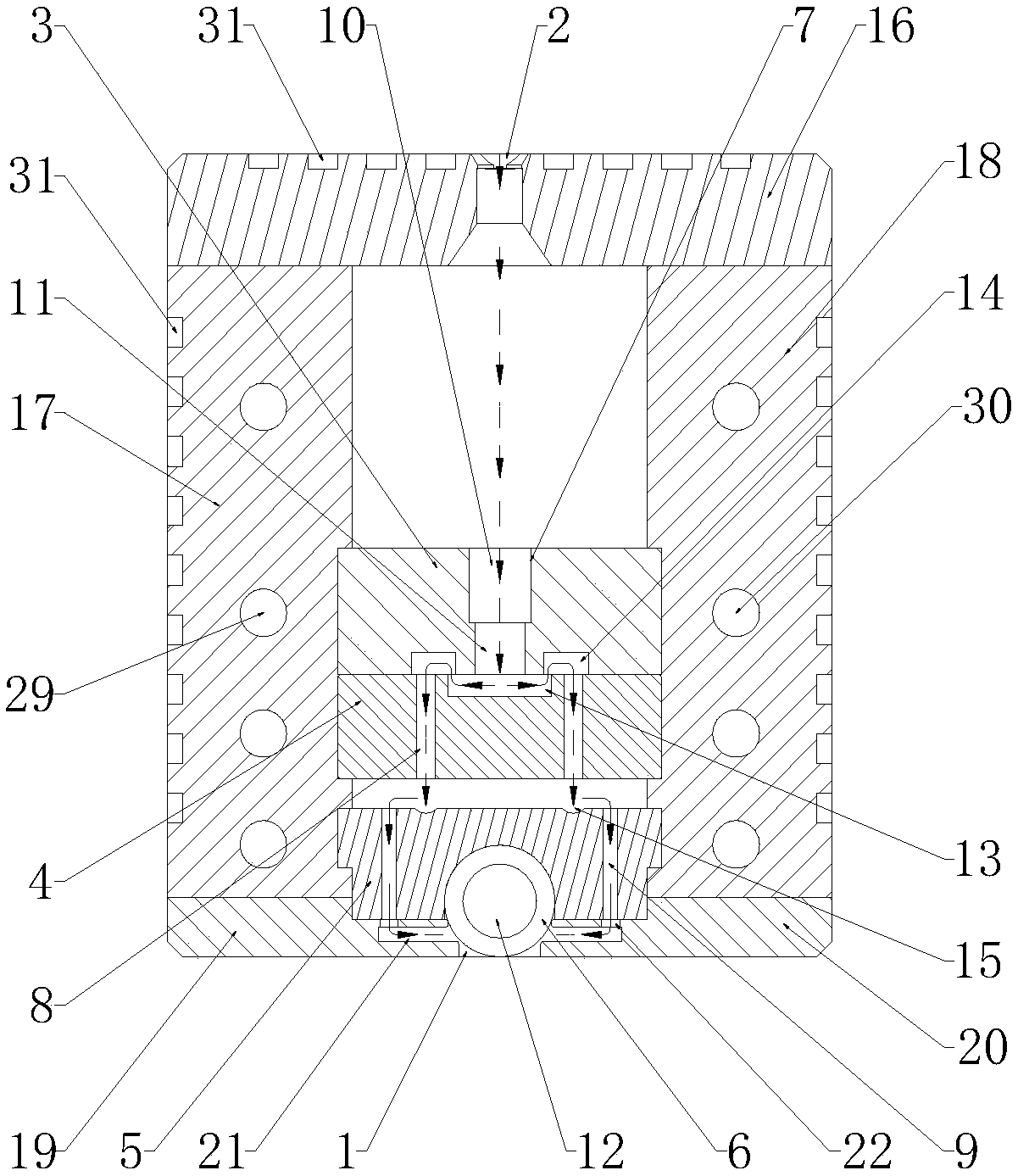

[0062] Such as Figure 1 to Figure 9 As shown, a linear plasma torch head includes a housing with a cavity, the bottom of the housing is provided with a bar-shaped outlet 1 communicating with the cavity, and the top of the housing is provided with an air inlet 2;

[0063] The first buffer plate 3, the second buffer plate 4, the third buffer plate 5, and the guide magnetic tube 6 are arranged in sequence from top to bottom in the cavity of the housing. Electrodes 12 are arranged in the guide magnetic tube 6, and the guide magnetic tube 6 The bottom end is located at the bar-shaped outlet 1 and is provided with a gap with the bar-shaped outlet 1. The first buffer plate 3, the second buffer plate 4, the third buffer plate 5, and the guide magnetic tube 6 jointly divide the cavity into independent first The buffer chamber, the second buffer chamber and the third buffer chamber, two fourth buffer chambers communicated with the strip outlet 1 are provided at the bottom of the shell,...

Embodiment 2

[0069] This embodiment makes the following further limitations on the basis of embodiment 1: the first buffer plate 3 is spaced apart from the top of the cavity;

[0070] The first mixing hole 7 includes a large-diameter section 10 and a small-diameter section 11 located below the large-diameter section.

Embodiment 3

[0072] This embodiment makes the following further limitations on the basis of embodiment 1: the upper end surface of the second buffer plate 4 is arranged in contact with the lower end surface of the first buffer plate 3;

[0073] The top of the second buffer plate 4 is provided with a first buffer groove 13 facing the first mixing hole group, and the width of the first buffer groove 13 is larger than the diameter of the bottom end of the first mixing hole 7;

[0074] The bottom end of the first buffer plate 3 is provided with two second buffer grooves 14, and the two second buffer grooves 14 are arranged symmetrically with respect to the first mixing hole group, and the second buffer grooves 14 are connected with the first buffer grooves 13 and the first buffer grooves. The second mixing hole groups are all connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com