A method for grain refinement of martensitic heat-resistant steel large-diameter thick-walled tube

A grain refining, heat-resistant steel technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as coarse grains or mixed grains, uneven radial structure and performance of finished pipes, and achieve performance uniformity. Improve, radial grain size uniformity is good, improve the effect of grain uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

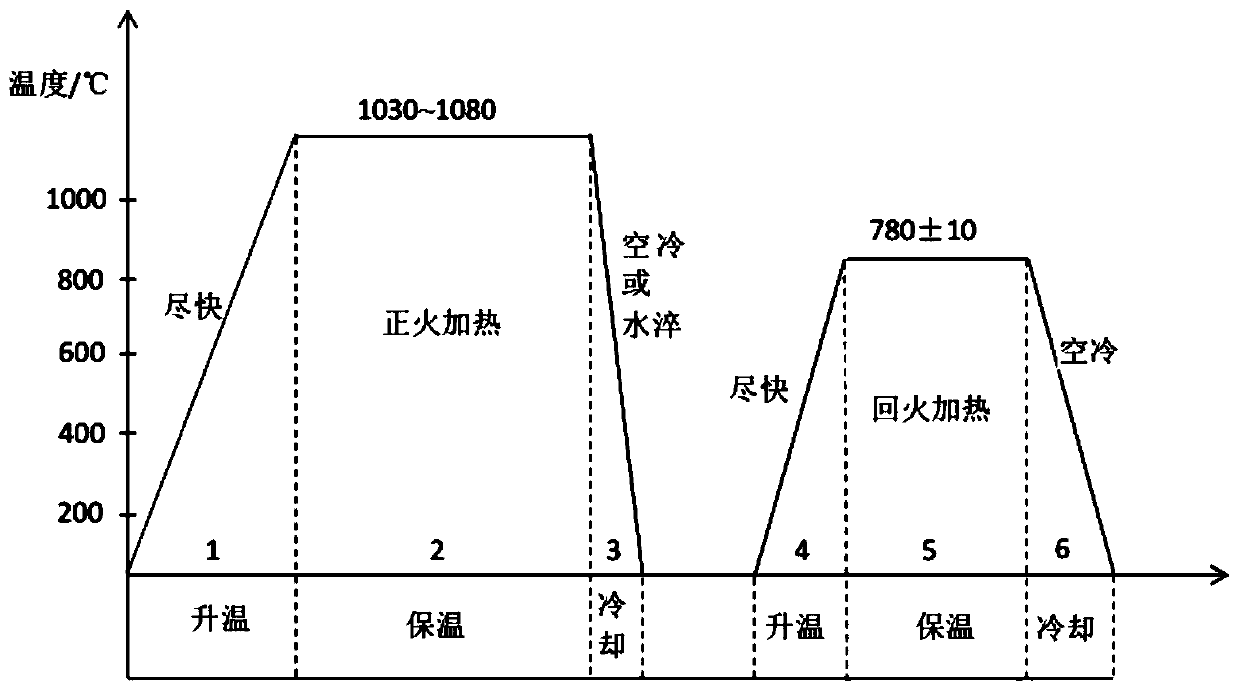

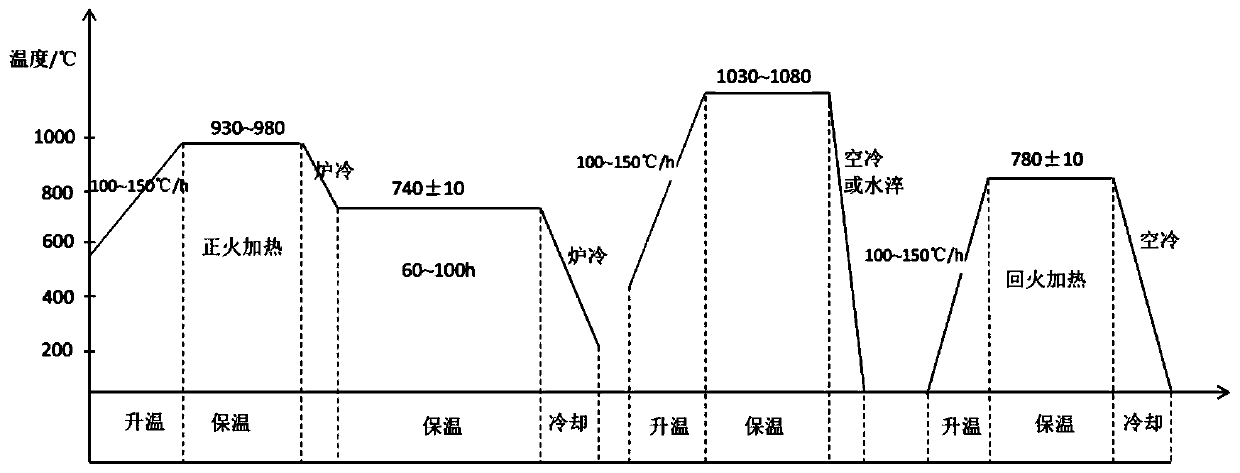

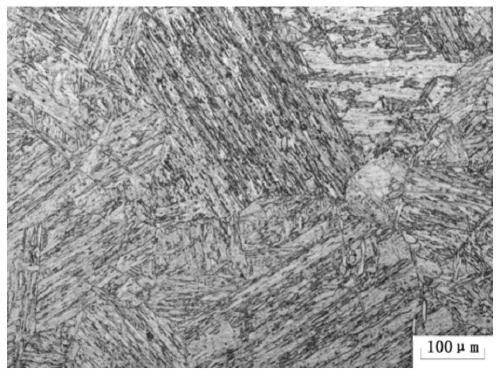

[0027] In the present invention, the pipe blank after hot extrusion of G115 martensitic heat-resistant steel, with a wall thickness of 150mm, is austenitized at 980°C before normalizing + tempering heat treatment, precooled to 745°C and kept for 75 hours, and then Furnace cools. Reheat to 1040°C, holding time 3 hours, water cooling; then proceed to 780°C, holding time 6 hours, air cooling. It not only refines the coarse grains of the G115 large-diameter thick-walled finished tube, but also improves the uniformity of the grains at different wall thickness positions, thus improving the uniformity of the radial structure and performance of the thick-walled tube.

Embodiment 2

[0029] In the present invention, the pipe blank after hot extrusion of G115 martensitic heat-resistant steel, with a wall thickness of 60mm, is austenitized at 930°C before normalizing + tempering heat treatment, precooled to 730°C for 60 hours, and then Furnace cools. Reheat to 1080°C, holding time 1.5 hours, water cooling; then proceed to 780°C, holding time 3 hours, air cooling. It not only refines the coarse grains of the G115 large-diameter thick-walled finished tube, but also improves the uniformity of the grains at different wall thickness positions, thus improving the uniformity of the radial structure and performance of the thick-walled tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com