Manufacturing method of working layer of icdp roll

A manufacturing method and working layer technology, which is applied in the field of metallurgical machinery roll casting, can solve the problems of increased raw material procurement costs, etc., and achieve the effects of high microhardness of the matrix, refined grains, and refined structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

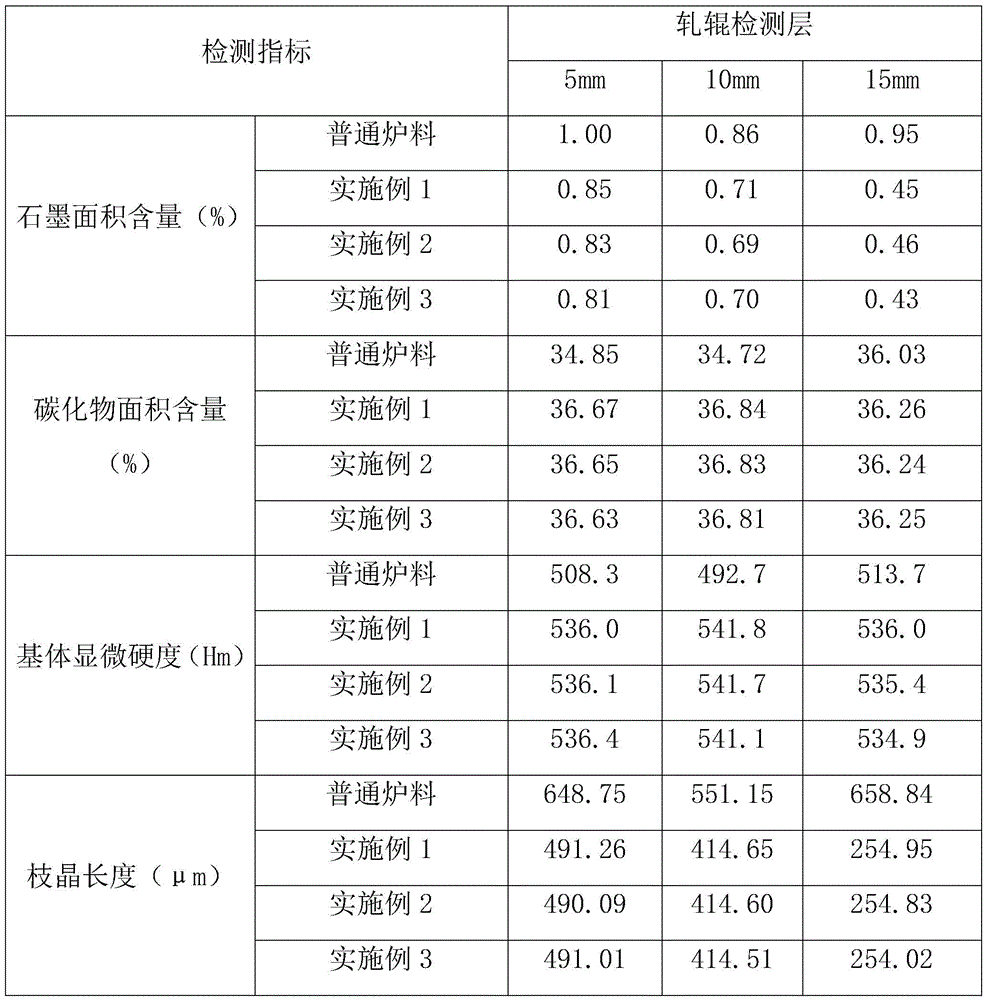

Examples

Embodiment 1

[0023] The manufacturing method of ICDP roll working layer, comprises the following steps:

[0024] ①Pre-melting treatment: Pig iron, iron filings, and returned furnace materials are prepared according to the composition ratio of the ICDP roll working layer, steelmaking pig iron 20%, iron filings + recycled materials 65%, and put into a 30t medium frequency induction furnace for melting; furnace materials are melted to molten iron After 1445°C, it is put into the treatment ladle, and the desiliconization agent (Anyang Huatai Metallurgical Furnace Charge Co., Ltd.), which accounts for 3% of the pre-melted molten iron, is added to the ladle in advance. The desiliconization agent has dual effects of desiliconization and dephosphorization. After the molten iron comes out of the ladle, the silicon and phosphorus elements in the molten iron will initially react with the desiliconization and dephosphorization; the spray gun is deep into the molten iron, and 0.25MPa nitrogen is sprayed...

Embodiment 2

[0029] The manufacturing method of ICDP roll working layer, comprises the following steps:

[0030] ① Pre-melting treatment: the pig iron, iron filings, and returned charge are prepared according to the composition ratio of the ICDP roll working layer, steelmaking pig iron 20%, iron filings + returned charge 65%, and put into the furnace for melting; the charge is melted to 1450°C of molten iron After being released into the processing ladle, a desiliconizing agent (Anyang Huatai Metallurgical Furnace Charge Co., Ltd.) accounting for 3% of the pre-melted molten iron is added to the ladle in advance. The desiliconizing agent has dual effects of desiliconization and dephosphorization. After the molten iron comes out of the ladle, the silicon and phosphorus elements in the molten iron will initially react with the desiliconization and dephosphorization; the spray gun is deep into the molten iron, and 0.25MPa nitrogen is sprayed into the passivated magnesium particles, and the pass...

Embodiment 3

[0035] The manufacturing method of ICDP roll working layer, comprises the following steps:

[0036]① Pre-melting treatment: Prepare pig iron, iron filings, and returned charge according to the composition ratio of the ICDP roll working layer, steelmaking pig iron 20%, iron filings + returned charge 65%, and put them into the furnace for melting; the charge is melted to molten iron at 1450°C After being released into the processing ladle, a desiliconizing agent (Anyang Huatai Metallurgical Furnace Charge Co., Ltd.) accounting for 3% of the pre-melted molten iron is added to the ladle in advance. The desiliconizing agent has dual effects of desiliconization and dephosphorization. After the molten iron comes out of the ladle, the silicon and phosphorus elements in the molten iron will initially react with the desiliconization and dephosphorization; the spray gun is deep into the molten iron, and 0.25MPa nitrogen is sprayed into the passivated magnesium particles, and the passivate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com