Textile cloth auto-cutting apparatus

A technology for textile fabrics and cutting devices, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of cloth scraps everywhere, can not be cleaned by cloth scraps, can not be completed by one person, etc., to achieve the effect of easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

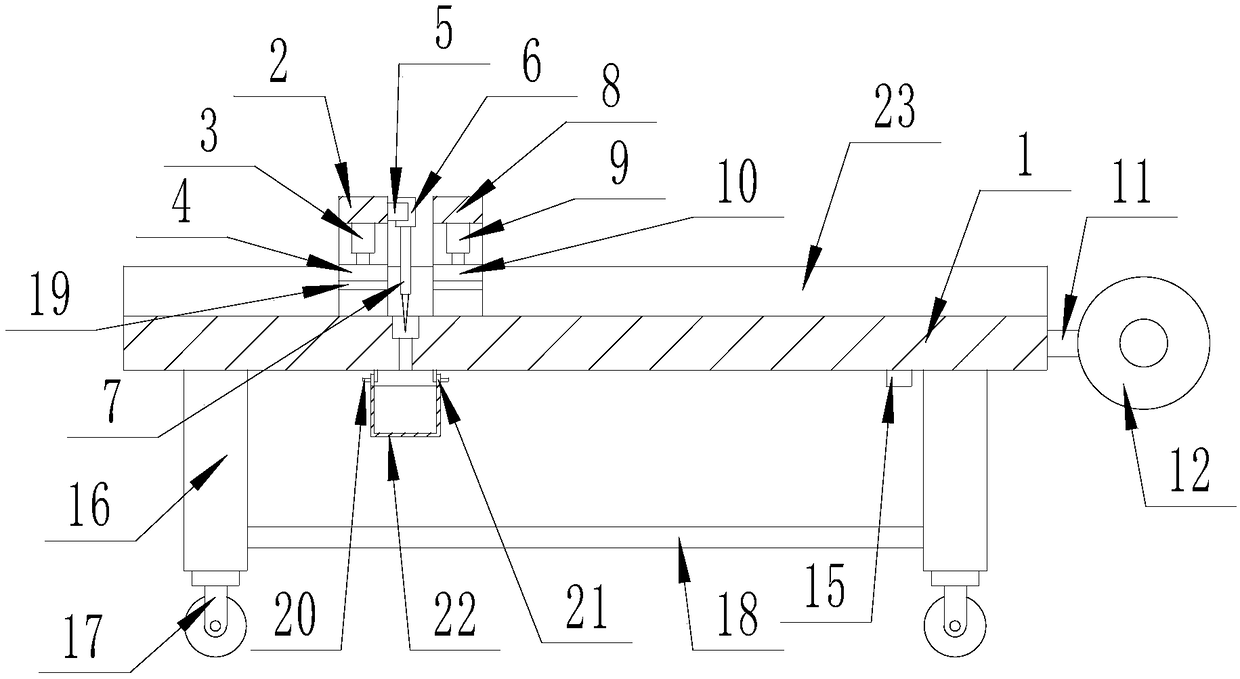

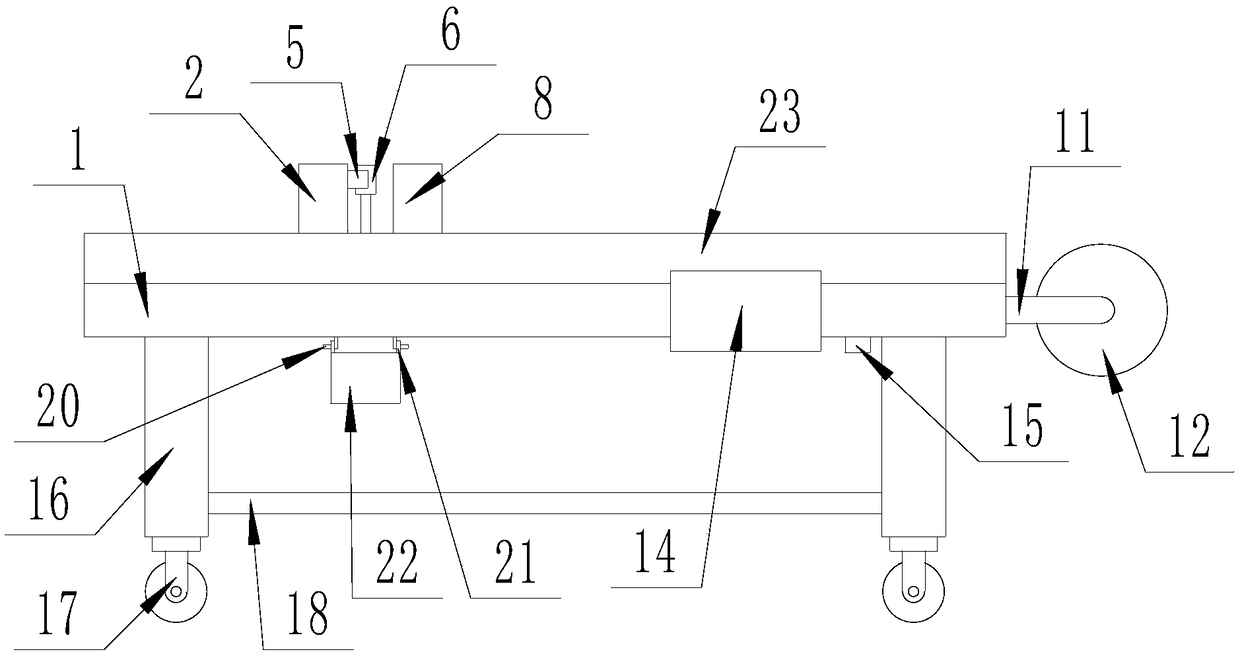

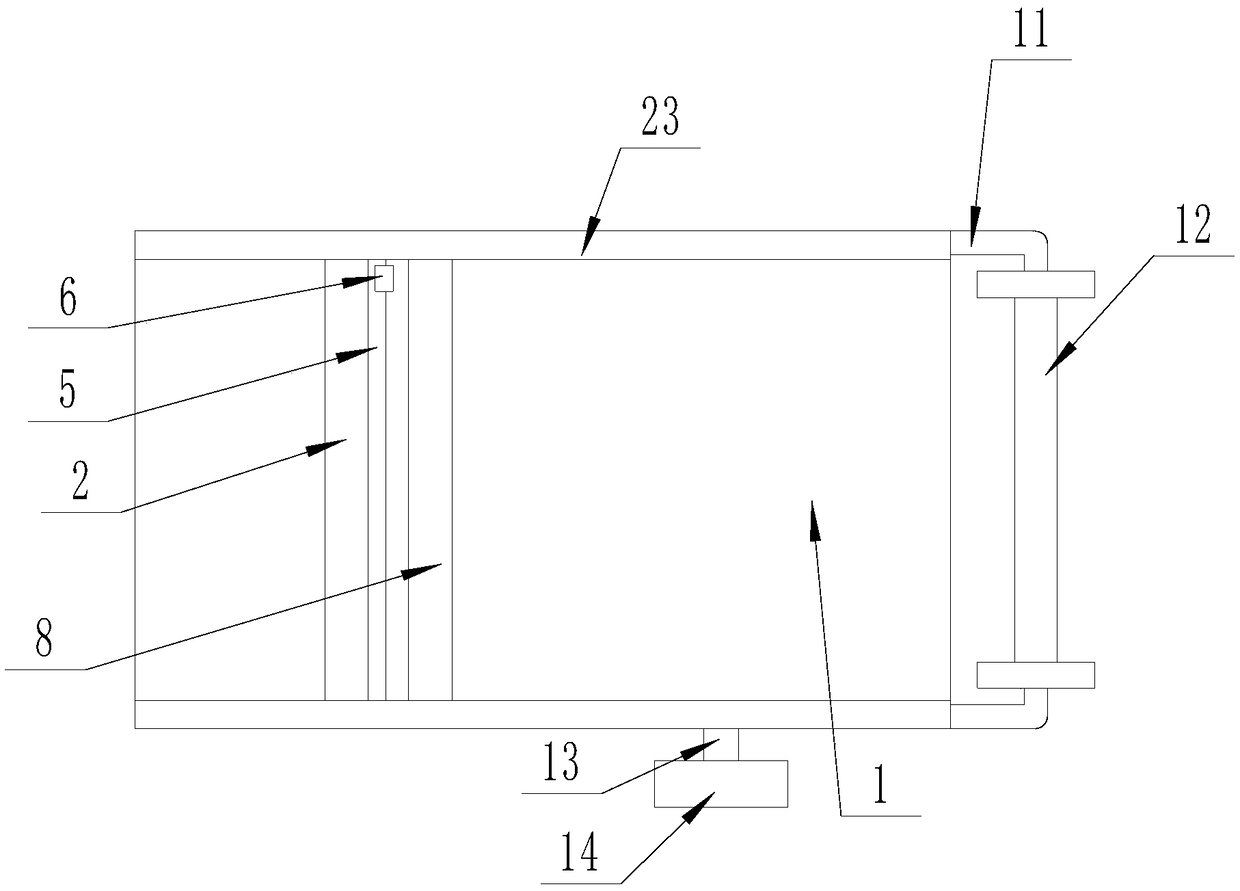

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, an automatic cutting device for textile fabrics includes a workbench 1, a No. 1 door frame 2 is provided on the left side of the upper surface of the workbench 1, and a number of telescopic end-to-end The No. 1 hydraulic telescopic rod 3 below, each telescopic end of the No. 1 hydraulic telescopic rod 3 is jointly connected with a No. 1 pressure plate 4, and the upper end of the right side surface of the No. 1 door frame 2 is provided with a guide rail 5, and on the guide rail 5 Slidingly connected with an electric slider 6, the lower surface of the electric slider 6 is provided with a cutting knife 7, and the upper surface of the workbench 1 is provided with a cutting groove on the right side of the No. 1 door frame 2. On the workbench 1 No. 2 gantry frame 8 is arranged on the surface and on the right side of the cutting groove, and a number of No. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com