Cloth cutting machine

A cutting machine and cloth technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of time-consuming and laborious, unable to achieve accurate cloth cutting, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

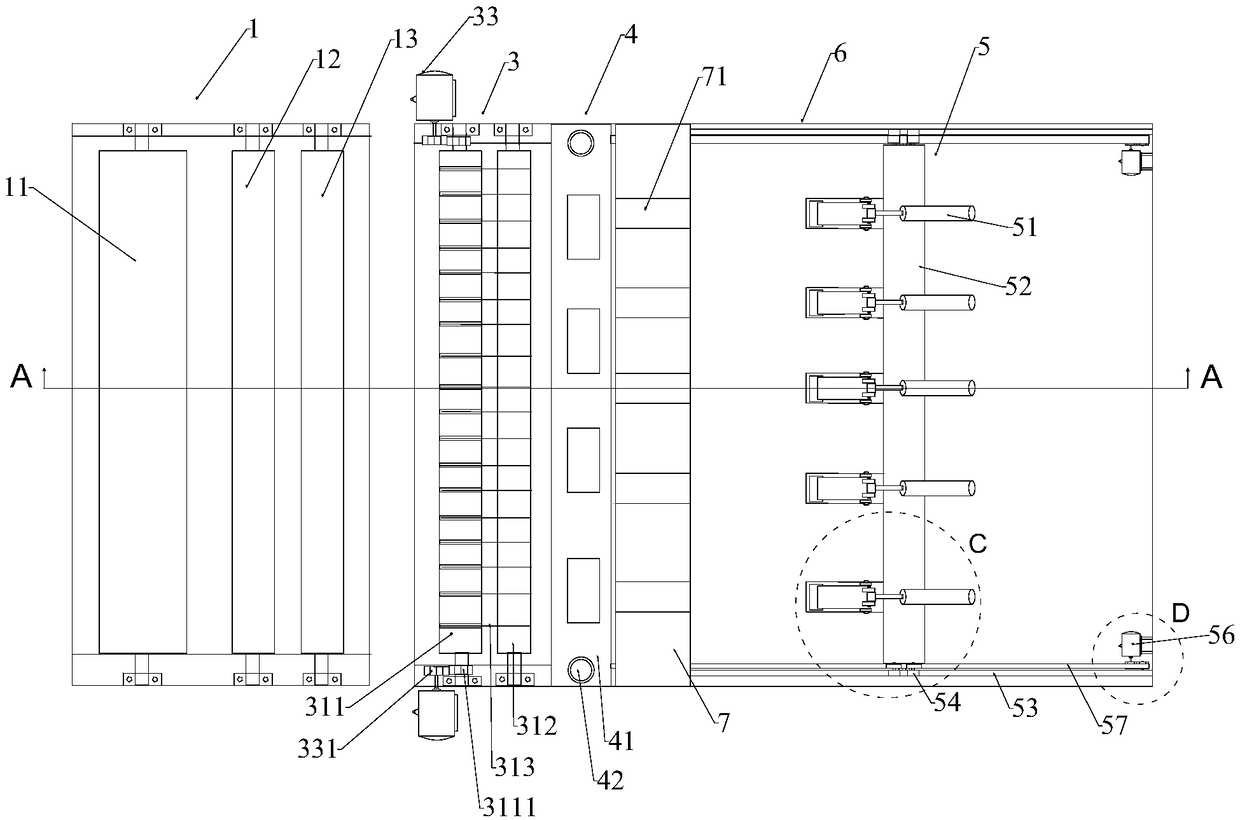

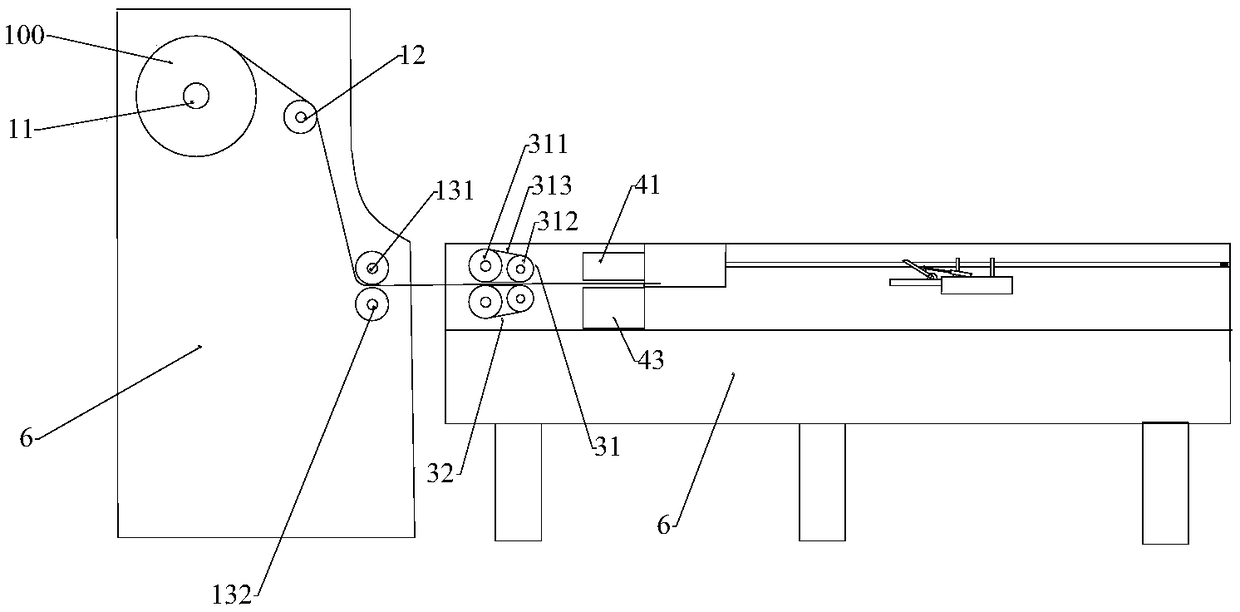

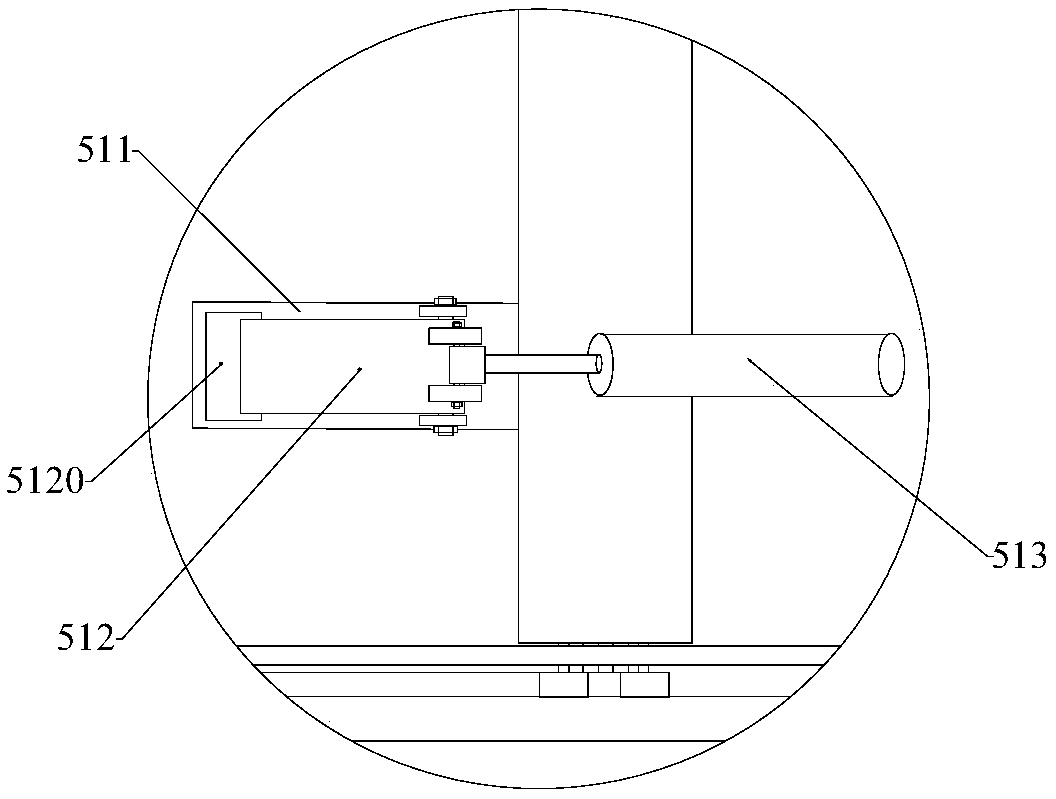

[0031] Embodiments of the present invention: as Figure 1-4 As shown, a cloth cutting machine is disclosed, including a spreading device 1, a leveling conveying device 3, a cutting device 4, a cloth pulling device 5 and a frame 6;

[0032] The spreading device 1 comprises a coiled material roller 11, an auxiliary roller 12 and a roller assembly 13, the two ends of the coiled material roller 11 and the auxiliary roller 12 are fixedly installed with bearings, and on the frame 6 There are bearing seats matched with each bearing, and the coil material roller 11 is rotated through the cooperation of the bearing and the bearing seat. The coil material roller 11 is covered with a coil material 100, and the coil material 100 is driven by the coil material roller 11. Rotation occurs. The auxiliary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com