Wooden door and wooden decorative board

A decorative panel and wood technology, applied in the direction of door leaves, windows/doors, building components, etc., can solve problems such as falling off, costing a lot of manpower, and affecting the appearance of door panels or decorative panels, so as to eliminate the use of adhesives and make it easier to match The effect of attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

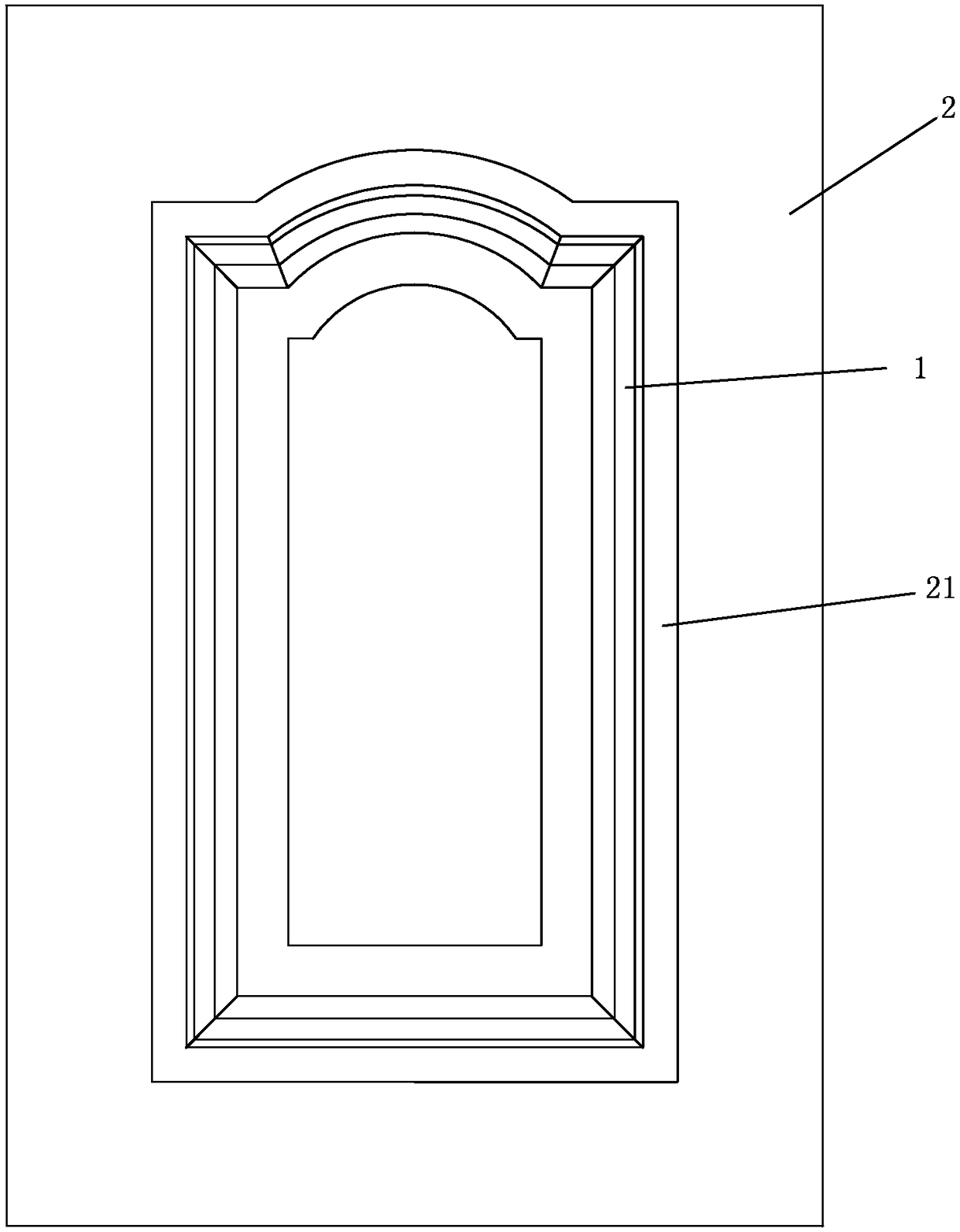

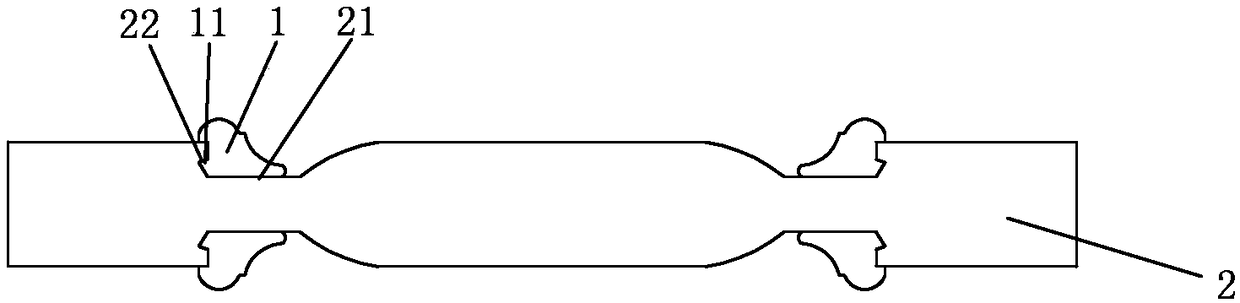

[0038] See Figure 1 to Figure 7 As shown, the wooden door of the present invention includes a door panel 2 and a decorative strip 1. A mounting groove 21 is provided on the surface of the door panel 2. The mounting groove 21 includes at least two sections, which are connected end to end in sequence to form a closed shape; The strip 1 includes at least two sections, which are connected end to end in sequence to form a closed shape; the decorative strip 1 and the mounting groove 21 have a one-to-one correspondence, and the shapes match each other;

[0039] The mounting groove 21 has a bottom surface and a side wall. A notch 22 is provided along the bottom of the side wall. The middle portion of each section of the decorative strip 1 is provided with a convex portion 11 that can be matched with the notch 22; 1 is a material with certain elasticity, and allows the protrusion 11 to be inserted into the notch 22 after being deformed.

[0040] The decorative strip 1 forming a closed shap...

Embodiment 2

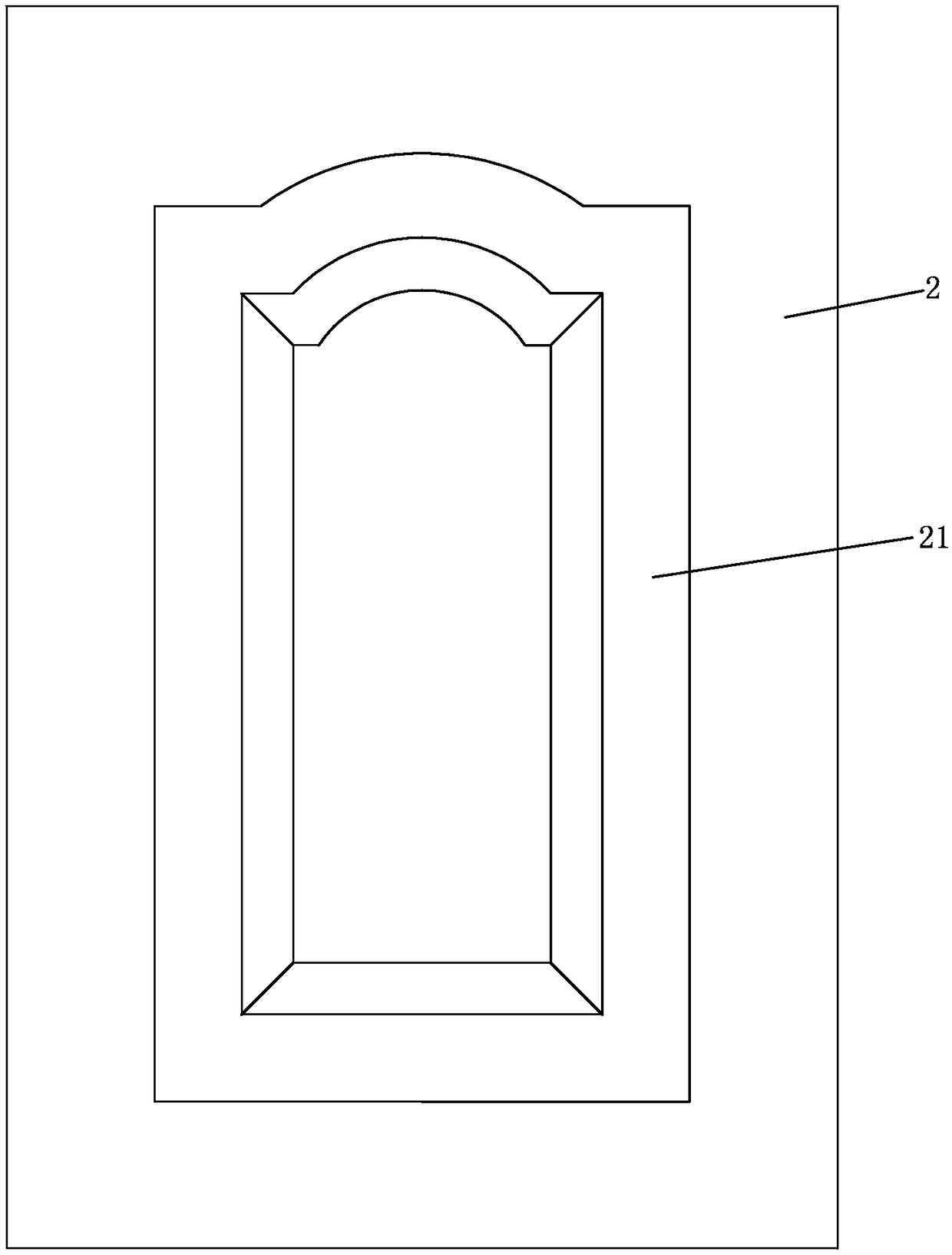

[0049] See Figure 8 to Figure 10 As shown, a wooden decorative board 3 includes a decorative board 3 and a decorative strip 1. A mounting groove 31 is provided on the surface of the decorative board 3, and the mounting groove 31 includes at least two sections, which are connected end to end in sequence to form a closed shape; Each segment of the decorative strip 1 includes at least two segments, which are connected end to end in sequence to form a closed shape; the decorative strip 1 and the mounting groove 31 have a one-to-one correspondence, and the shapes match each other;

[0050] The mounting groove 31 has a bottom surface and a side wall. A notch 32 is provided along the bottom of the side wall. The middle part of the decorative strip 1 is provided with a convex part that can be matched with the notch 32; the decorative strip 1 has A certain elastic material, so that the protrusion can be inserted into the notch 32 after being deformed.

[0051] The decorative strip 1 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com