Sulfur concentrate concentration and dehydration process

A technology of concentrated dehydration and sulfur concentrate, which is applied in the field of mining metallurgy, can solve the problems of low foam surface tension, excessive sulfur content in products, overflow and muddy overflow, etc., to eliminate the use of flocculants, improve concentration efficiency, and avoid overflow The effect of running muddy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

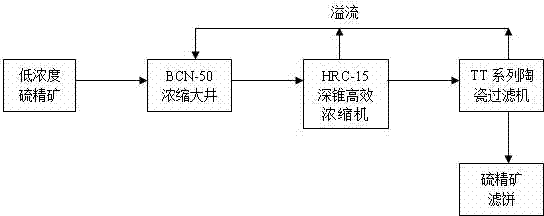

[0024] Such as figure 1 Shown is the process flow diagram of the present invention, the present invention is a kind of sulfur concentrate concentration dehydration process, comprises two-stage concentration flow process, concrete steps are:

[0025] (1) Transport the low-concentration sulfur concentrate to the BCN-50 concentration well for primary concentration;

[0026] (2) The sulfur concentrate after the primary concentration is trickled and transported to the HRC-15 deep cone high-efficiency thickener for secondary concentration, and the overflow generated by the HRC-15 deep cone high-efficiency thickener is returned and transported to the BCN-50 thickening w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com