Double-suction submerged pump

A submerged pump and pump shaft technology, applied in the direction of pumps, pump devices, pump components, etc., can solve problems such as large volume loss, leakage in the high-pressure area on the back, and continued use of the pump body structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

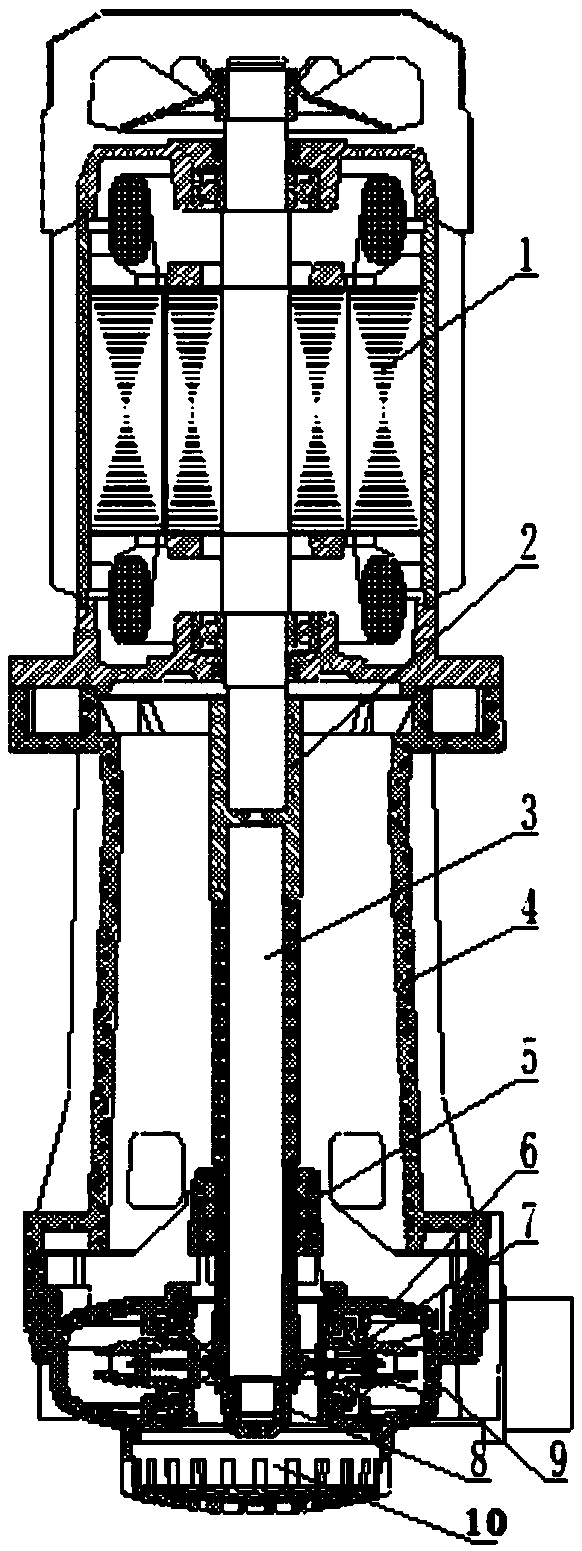

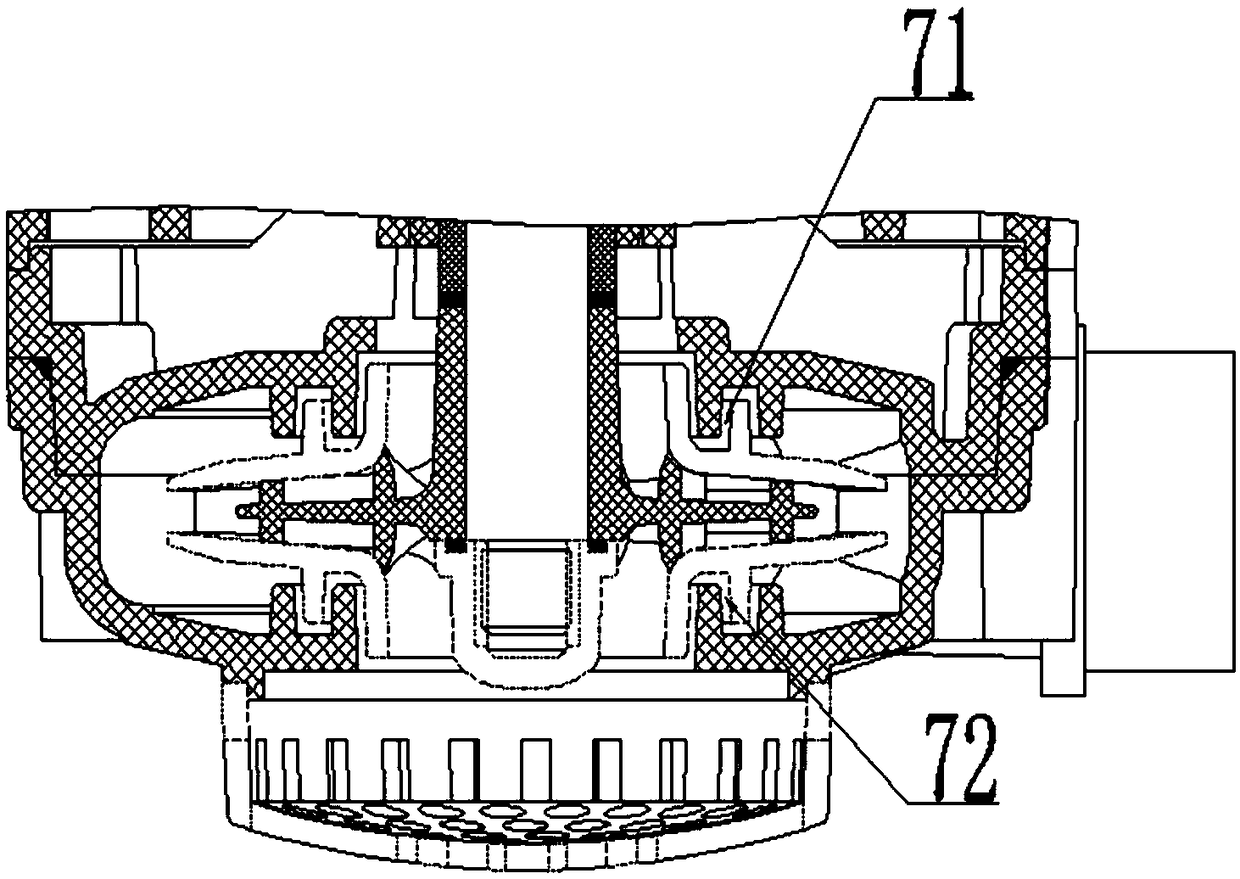

[0016] Such as figure 1 As shown, in the schematic diagram of the structure of the double-suction submersible pump of the present invention, the double-suction submersible pump includes a motor 1, a coupling 2, a pump shaft 3, a bracket 4, a sliding bearing 5, a pump cover 6, and an impeller 7. , Shaft cap 8, pump body 9, filter screen 10 and so on. The double-suction liquid pump is a double-suction structure. It can be understood that the impeller 7 is a symmetrically arrange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap