Wall corner vertical type forced-convection heat transfer device

A technology of forced convection and heat exchange devices, which is applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchanger types, etc., can solve the problems of air not circulating, unfavorable for people to breathe fresh air, unevenness, etc., and achieve high Air purification and circulation, avoiding local overheating, and improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

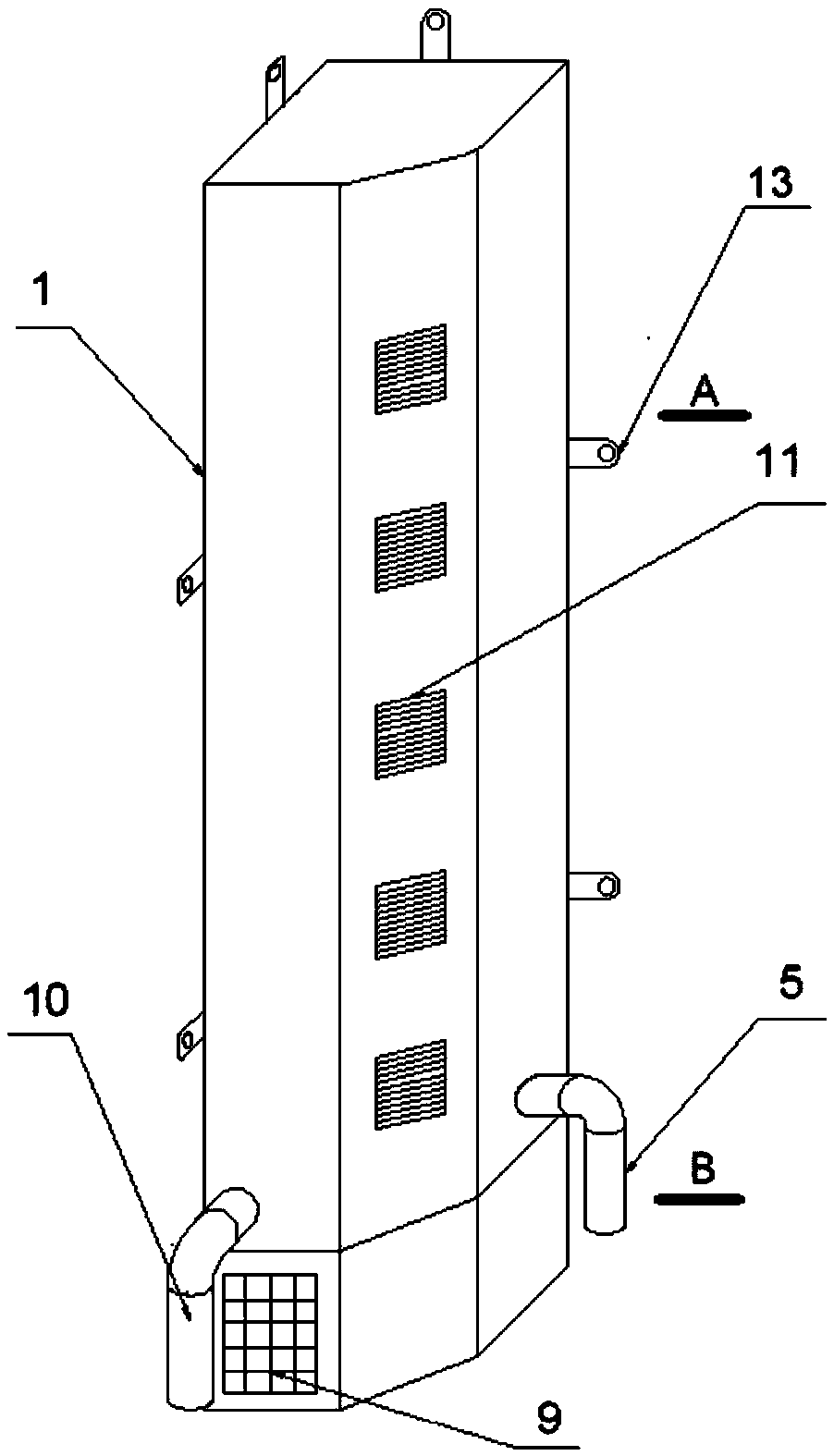

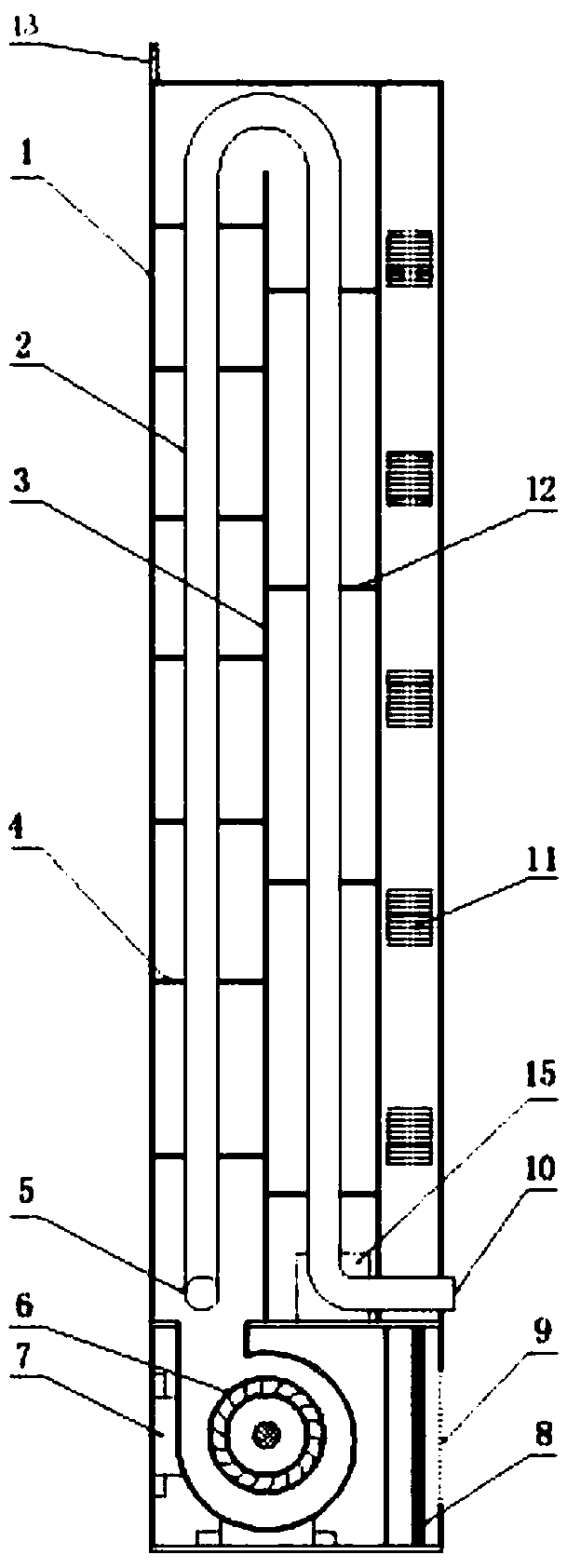

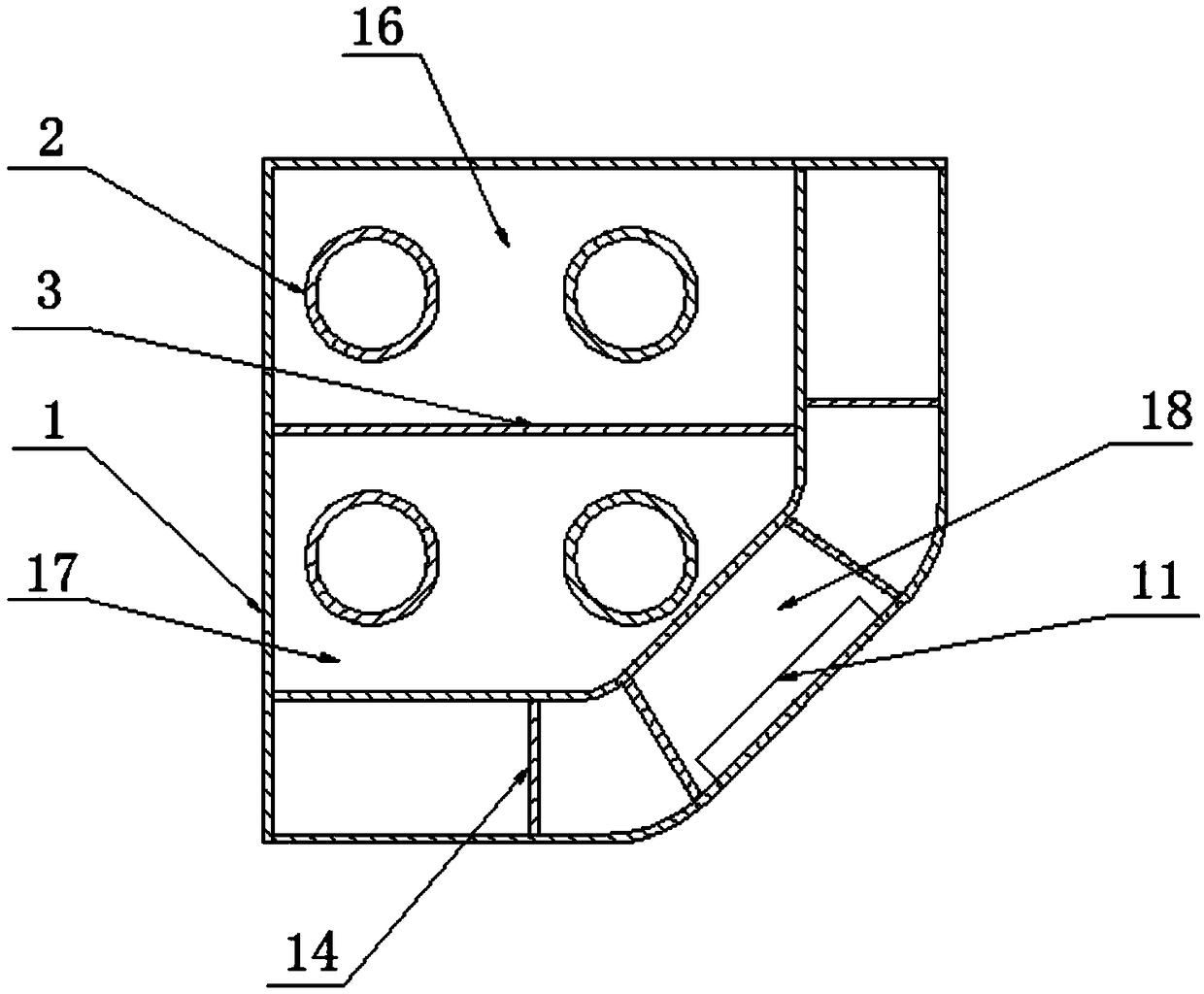

[0026] Specific embodiment: this device is placed in the corner position of the room, press figure 1 As shown in the three-dimensional structure, the left side and the rear side are respectively kept in contact with the two wall surfaces at the corner, and then the fixing ears 13 at various positions are used to fix the device to the wall to ensure the installation stability of the device . The total height of the device is about 3m, and its horizontal cross-sectional size is 200×200mm, the occupied area is small, and the spatial position of the corner of the wall can be reasonably utilized. A fan 6 is installed on the lower part of the housing 1, the air outlet of the fan 6 is directly connected to the heat exchange air duct on the upper part, the air inlet of the fan 6 communicates with the air inlet 9 opened on the housing 1, and the filter 8 is installed on both sides. position between them. When the fan is working, the air is sucked in from the air inlet 9, and after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com