Bouncing-prevention buffer mechanism of low-voltage switch

A low-voltage switch and buffer mechanism technology, applied in the contact drive mechanism, contact vibration/impact damping, etc., can solve the problems of poor stability of the anti-bounce device, and achieve the effects of convenient installation and maintenance, flexible rotation, and reduced maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

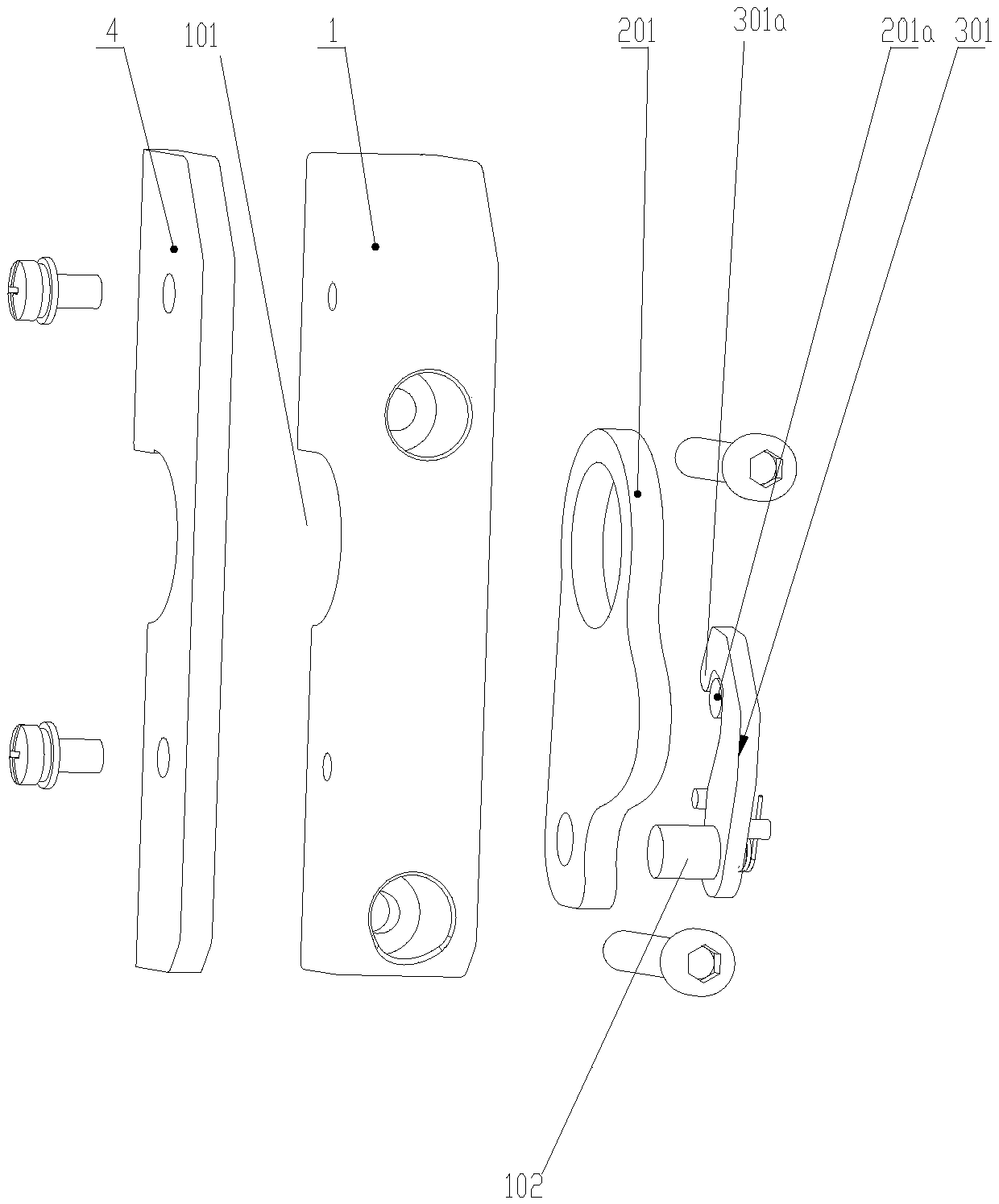

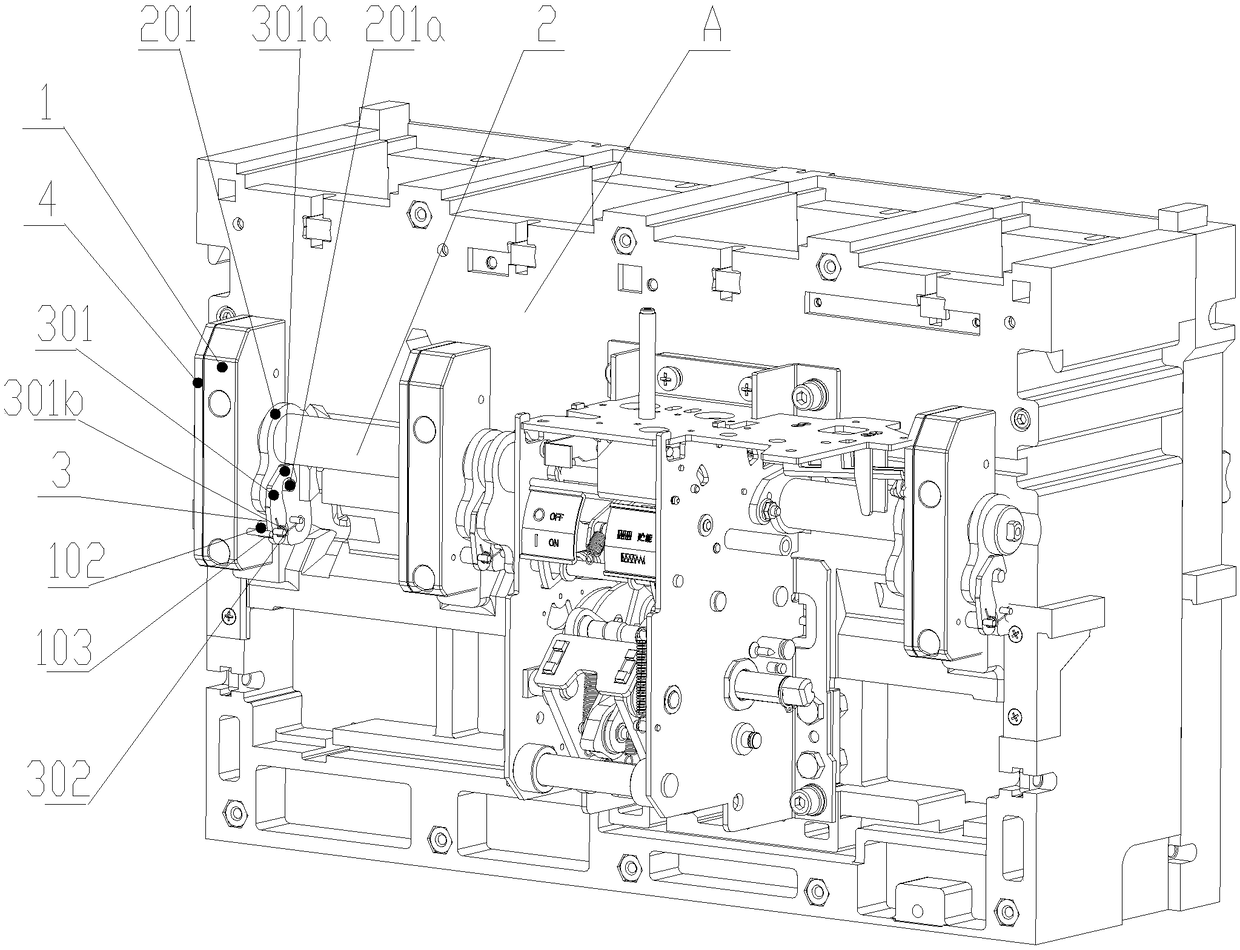

[0024] as attached figure 1 and 3 As shown, a low-voltage switch anti-bounce buffer mechanism, which includes a mechanism main shaft support 1, the upper and lower ends of the main shaft support 1 of the mechanism are mounted on the circuit breaker base A with screw locks, and the main shaft support 1 of the mechanism is provided with Half slot hole 101, the mechanism spindle 2 passes through the half slot hole 101 and is located in the space formed by the half slot hole 101 and the surface of the base A, wherein, the inner surface of the mechanism spindle support 1 is provided with an anti-bounce module 3 , the anti-bounce module 3 includes a resistance plate 301, the resistance plate 301 is installed on the support shaft 102 protruding from the inner side of the main shaft support 1 of the mechanism, the resistance plate 301 is provided with a clamping hook 301a, the A protrusion 301b is provided on the outer surface of the resistance plate 301 , and a torsion spring 302 is...

Embodiment 2

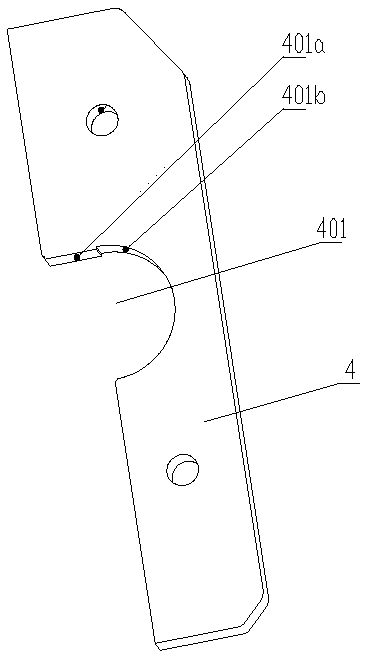

[0030] as attached Figure 5 , as shown in 6 and 8, the present invention also provides an embodiment that on the basis of embodiment 1, the inner surface of the main shaft support 1 of the mechanism is also equipped with an elastic buffer part 2 5, and the cantilever 201 of the main shaft 2 of the mechanism A stop rod 201b is provided.

[0031] as attached Figure 7 As shown, when the circuit breaker is opened, the stop rod 201b is in contact with the surface of the elastic buffer member 25 to absorb excess energy generated during the opening process and form resistance, thereby effectively reducing bouncing.

[0032] The invention provides an anti-bounce buffer mechanism for a low-voltage switch. An anti-bounce module is installed on the side of the bracket of the cantilever of the main shaft of the fixing mechanism. The buffer is installed on the bracket to play the role of buffer force, and the anti-bounce device and the bracket are combined into one. , not only can fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com