Contact terminal assembled from at least two parts

A contact terminal and component assembly technology, which is applied in the direction of contact components, contact manufacturing, connection device components, etc., can solve the problem of not having the same or equivalent force distribution, and achieve the effect of optimizing the contact tongue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

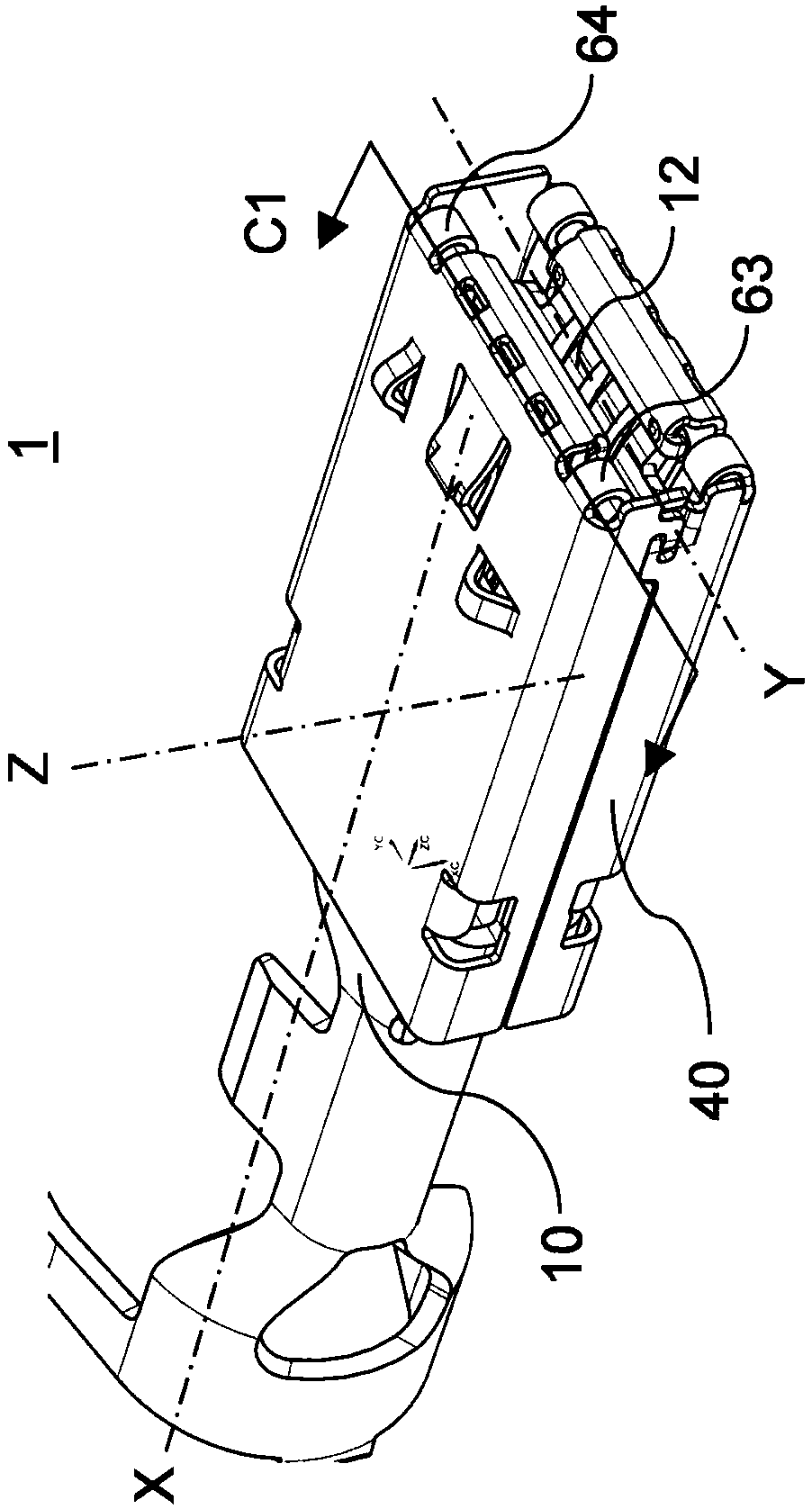

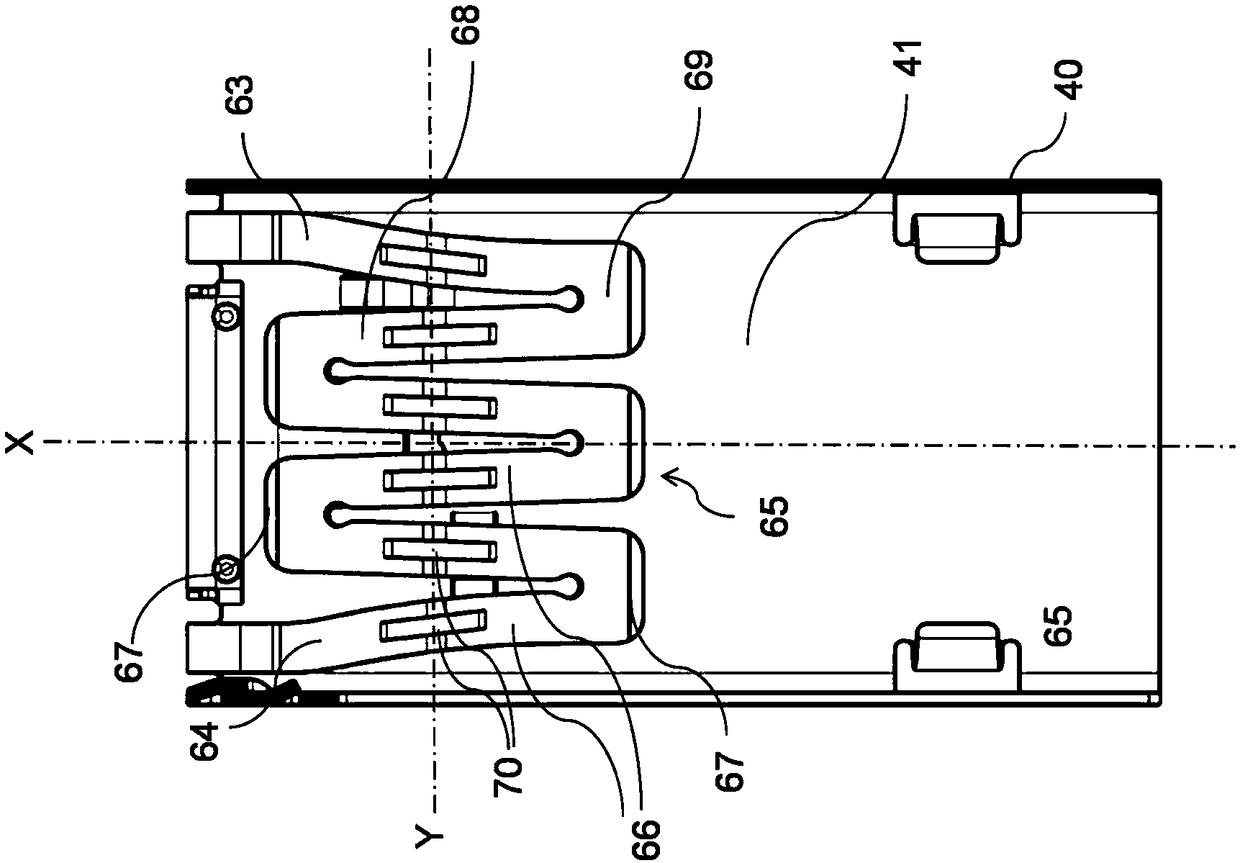

[0030] figure 1 Shown is a contact terminal 1 assembled from at least two parts, comprising a base part 10 having a plurality of contact tongues 12 aligned along a mating axis X, adapted to pass through a plurality of contacts The contact surface 13 on the tongue 12 ( Figure 4 ) contact the male connector pin. The sleeve 40 is adapted to be arranged at least partially over the base part 10 . The first arm 63 and the second arm 64 protrude from the sleeve 40 along the mating axis X inside the sleeve 40 . The sleeve 40 has a rectangular cross-section and the sleeve walls are aligned along the transverse axis Y and the vertical axis Z. The transverse axis Y is arranged perpendicular to the mating axis alignment X and the vertical axis alignment Z. The vertical axis Z is arranged perpendicular to the mating axis X and the transverse axis Y.

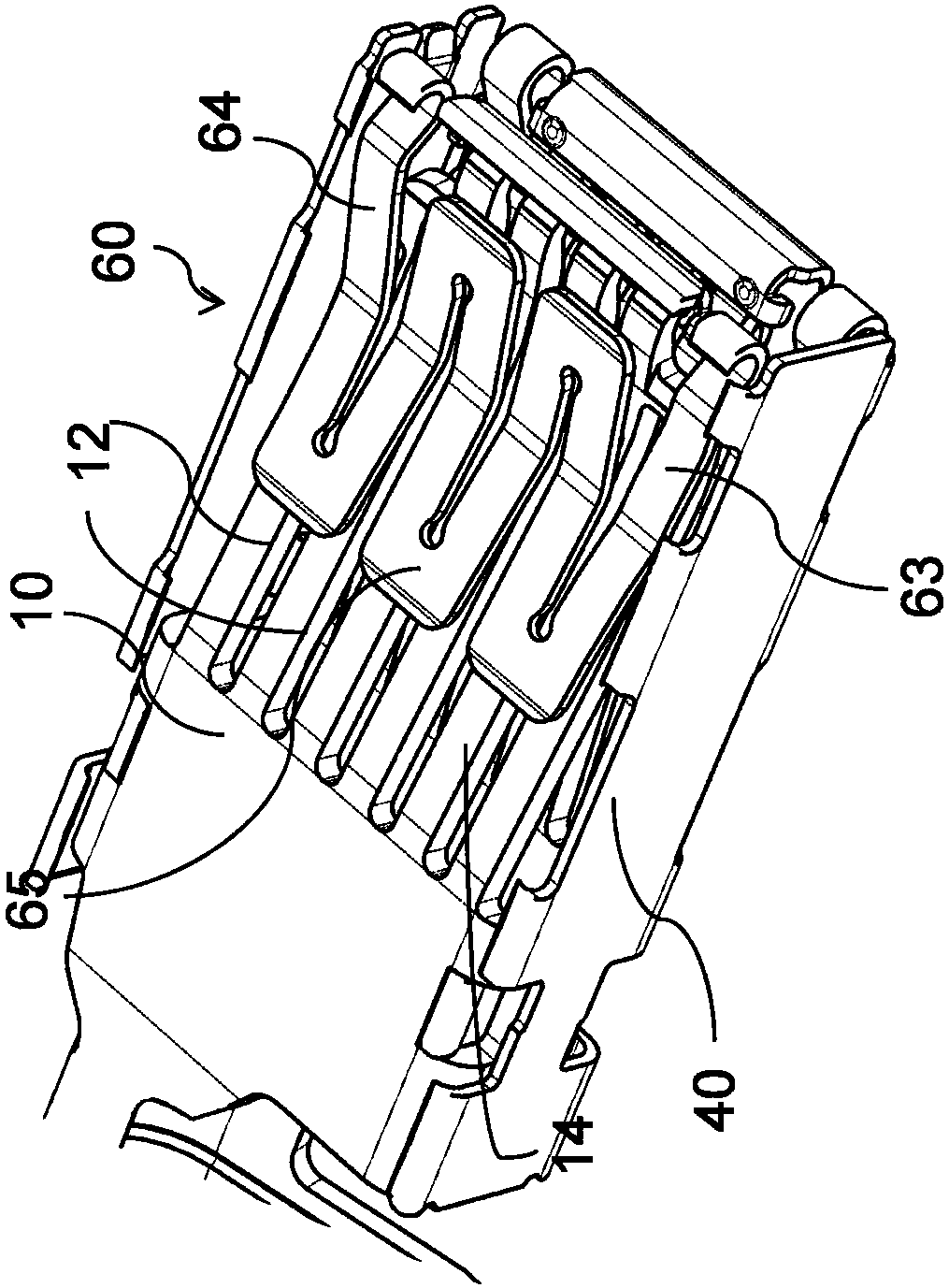

[0031] figure 2 show figure 1 A cross-sectional view of , wherein cutting is performed along cutting line C1. The sleeve 40 has at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com