Punching equipment for motorcycle accessory production

A technology for punching equipment and motorcycles, applied in vehicle parts, metal processing equipment, punching tools, etc., can solve the problem of not being able to take out and collect parts, and achieve the effect of reducing production efficiency, improving efficiency, and strong linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

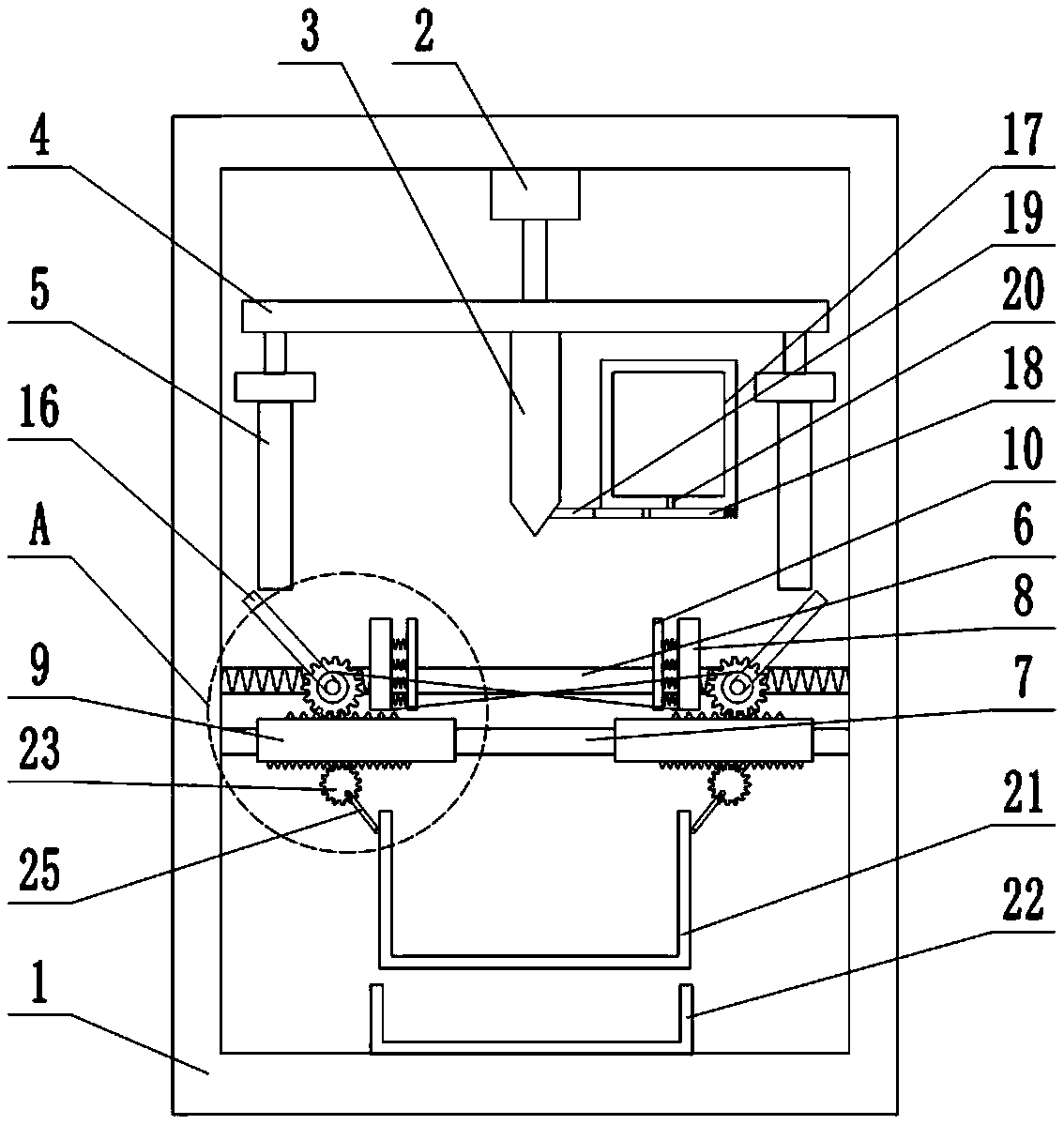

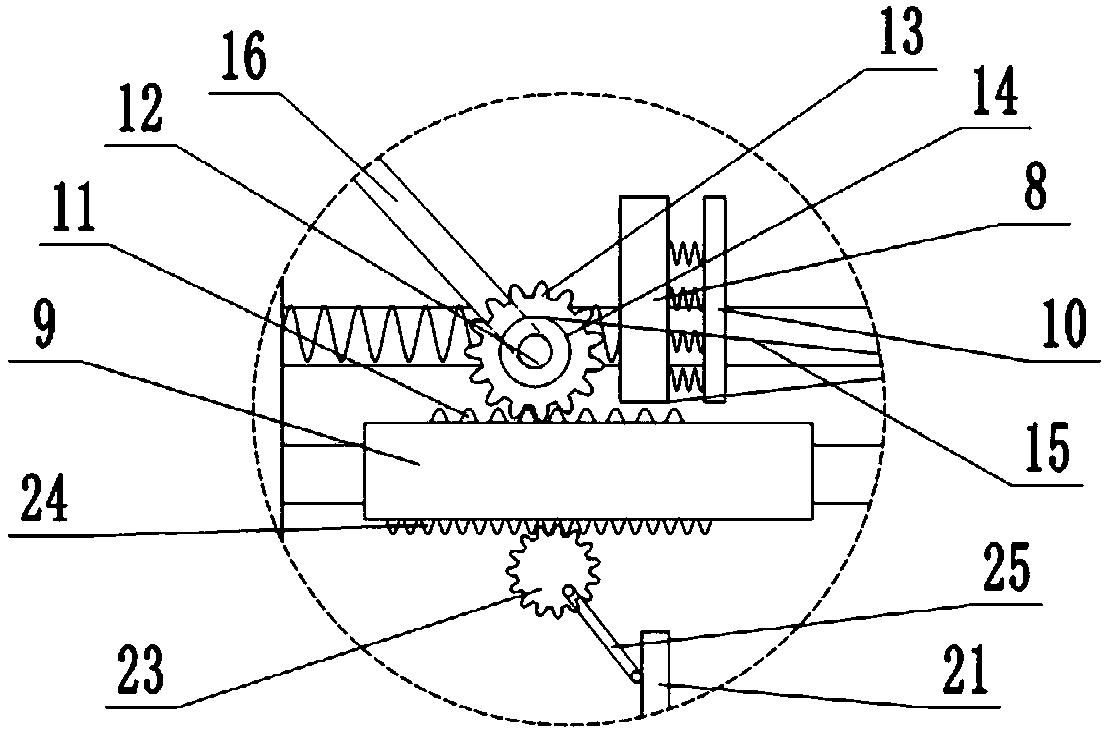

[0023] basically as figure 1 Shown: the punching equipment used to produce motorcycle accessories, including frame 1, cylinder 2, punching head 3, clamping block 8 and placing table 9. The cylinder 2 is fixed on the frame 1 by bolts, the output shaft of the cylinder 2 is fixed with a support 4, the punching head 3 is fixed on the middle part of the support 4 by bolts, and both sides of the support 4 are fixed with pressure blocks 5; figure 2 As shown, the first slide rail 6 and the second slide rail 7 are welded on the frame 1, and there are two clamping blocks 8 which are slidably connected to the two ends of the first slide rail 6. The connection between the clamping block 8 and the frame 1 There are springs connected between them. The clamping blocks 8 are provided with elastic layers, and the elastic layers of the two clamping blocks 8 are opposite; There are two placing platforms 9 and they are slidably connected to both ends of the second slide rail 7 , and a first ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com