A waste material collection device on a cutting machine for processing transmitter casings

A waste collection and cutting machine technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as danger, inconvenience, and troublesome unloading of waste, and achieve improved safety and high friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

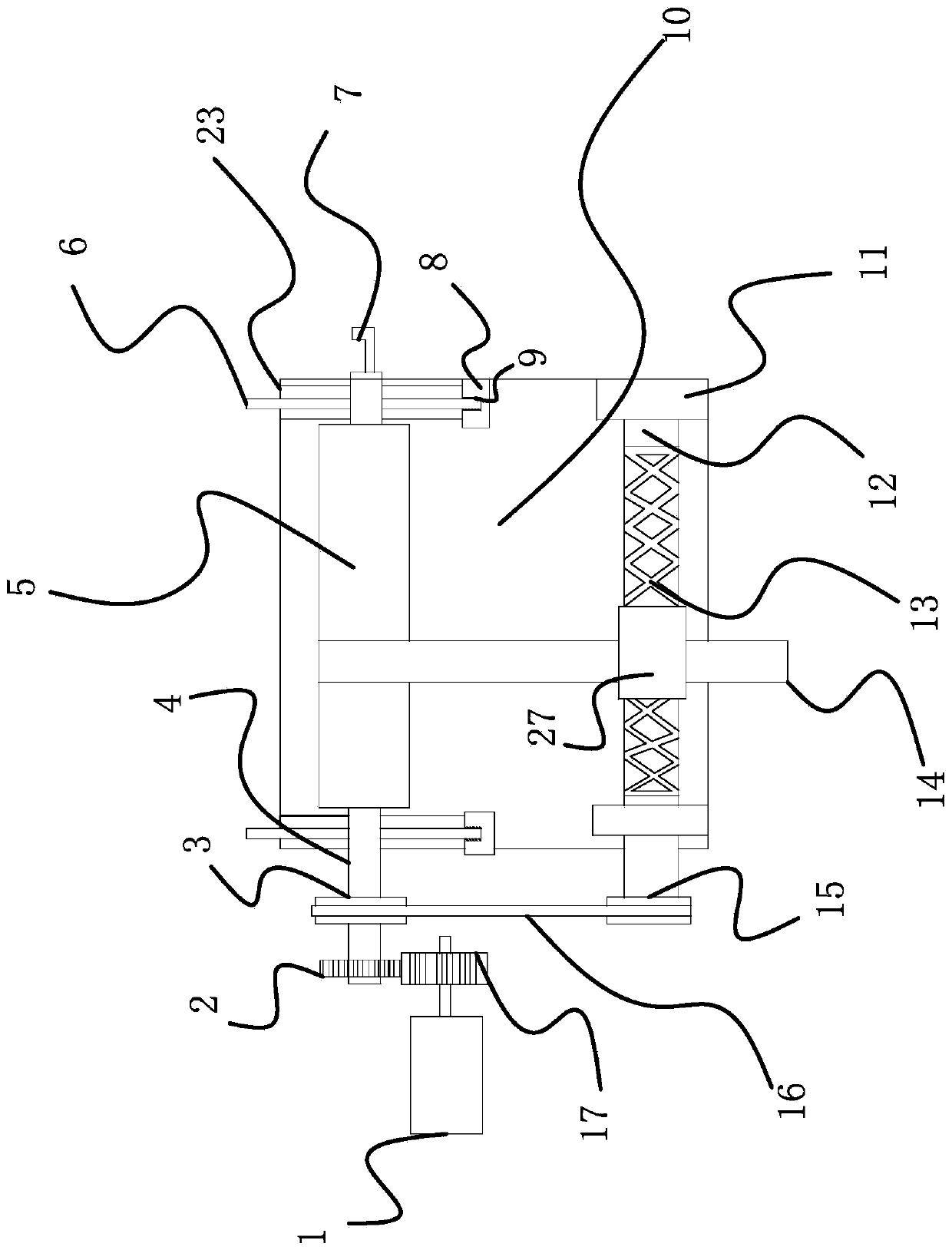

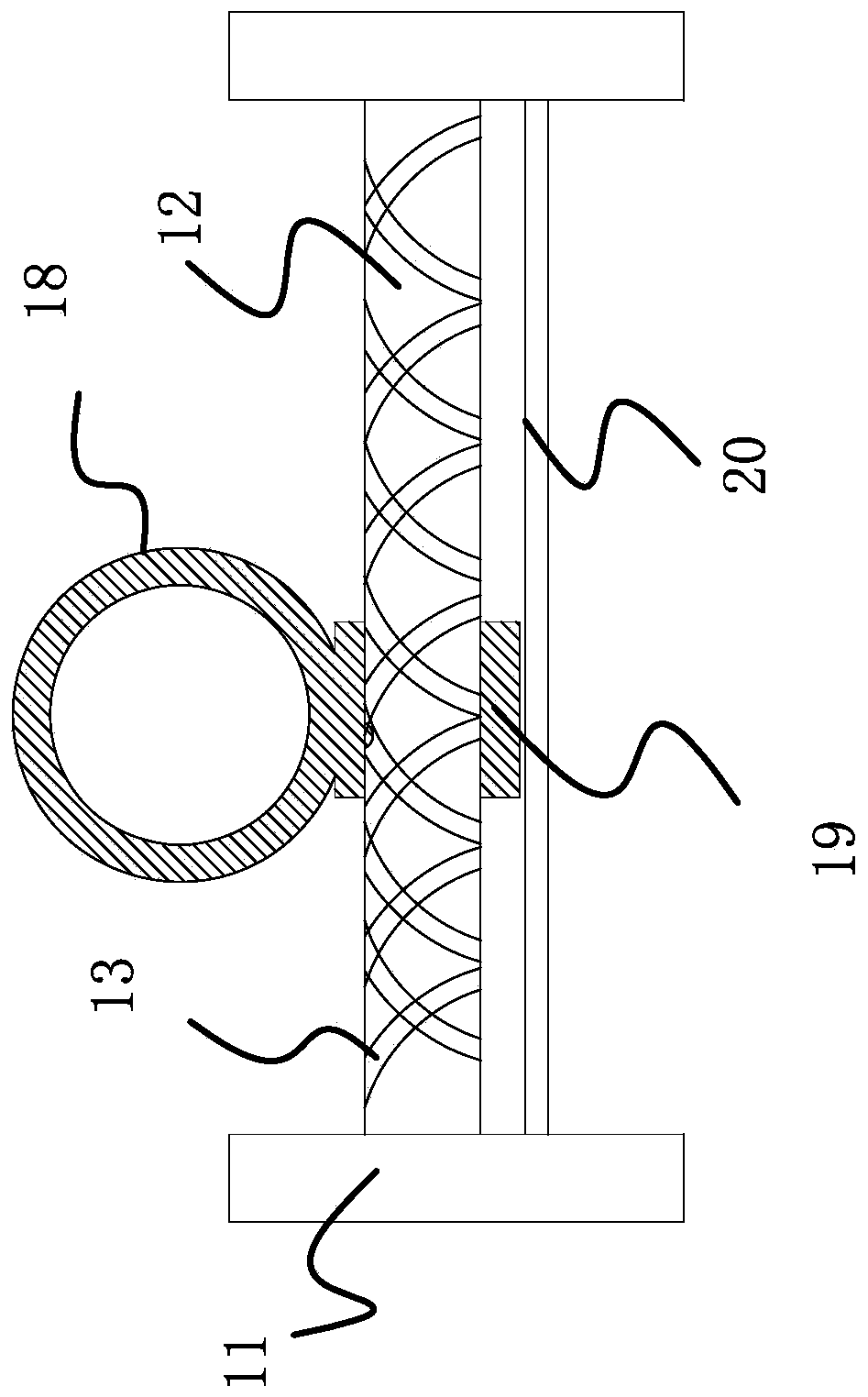

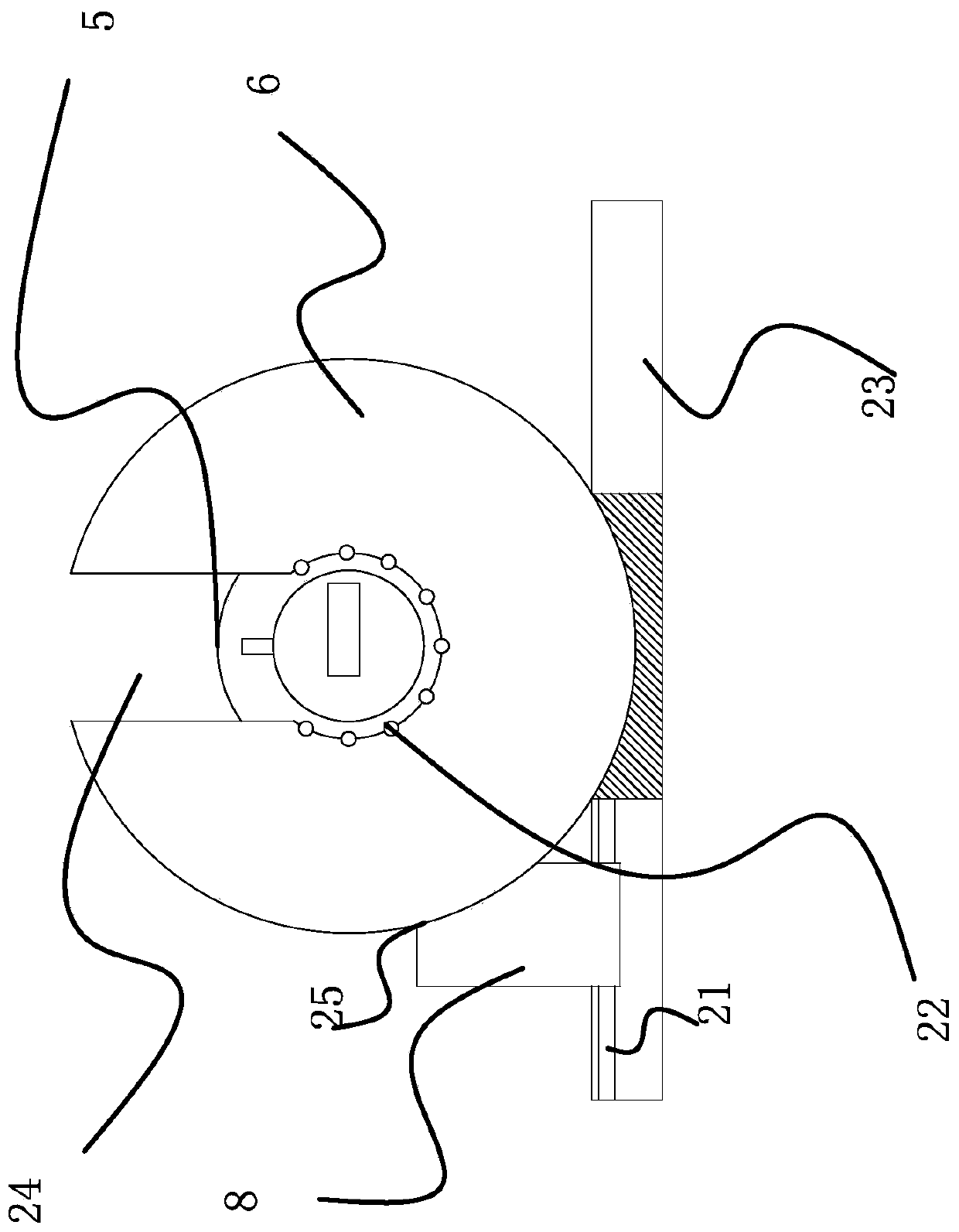

[0026] The following are specific embodiments of the present invention and the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0027] like figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of waste collection device on the cutting machine of processing transmitter chassis, it comprises machine base 10, winding mechanism, guide mechanism and transmission mechanism, it is characterized in that, described guide mechanism is arranged on the front of winding mechanism and Both are arranged on the machine base 10, and the transmission mechanism is connected between the guide mechanism and the winding mechanism. The winding device includes a winding rod 4 with a driven gear 2 at the end, and a winding rod 4 sleeved on the winding rod 4. The disc 6, the support seat 23 for placing the disc 6 with semicircular grooves on the surface and the block 8 slidingly connected to the support seat 23, the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com